PAGE 40 — INDUSTRIAL GENERATOR SETS — APPLICATION & INSTALLATION MANUAL — REV. #4 (09/07/07)

MECHANICAL INSTALLATION — FUEL SYSTEM (GASEOUS FUELS)

Gaseous Fuels

Some MQ Power Industrial generator sets may utilize

gaseous fuels such as Pipeline natural gas or Liquid

Petroleum Gas (LPG). Regardless of the fuel used, the

primary factors in successful installation and operation of a

gas fuel system are:

The gas supplied to the generator set must be of

acceptable quality.

The gas supply pressure must be measured to ensure

that the gas supply at the generator set, not just at the

source, is of proper pressure must be available while the

generator is running at full load.

The gas must be supplied to the genset in sufficient

volume to support proper operation.

Gaseous fuels are actually a mixture of several different

hydrocarbon gases and various contaminants, some of

which are potentially damaging to an engine over time.

The quality of the fuel is based on the amount of energy

per unit volume in the fuel and the amount of contaminants

in the fuel. Most gaseous fuel suppliers can provide a

fuel analysis that describes the chemical makeup of the

fuel that is to be provide to insure that the fuel is usable

for a specific application, and also to verify that the BTU

content of the fuel is sufficient to provide necessary kW

output of the genset.

Energy Content

One of the most important characteristics of gaseous

fuel used in a generator set is the heat value of the fuel.

The value of a fuel describes how much energy is stored

in a specific volume of the fuel. Gaseous fuel has a low

heat value (LHV) and a high heat value (HHV). The low

heat value is the heat available to do work in an engine

after the water in the fuel is vaporized. If the low heat

value of the fuel is too low (generally below 905 BTU/ft

3

)

the engine will not be able to maintain full output power

and may not produce rated power at standard ambient

temperature conditions.

Pipeline Natural Gas

The most common gaseous fuel for generator sets is

called

Pipeline natural gas

. In the United States, "dry

pipeline natural gas" has specific qualities based on

federal requirements. U.S. pipeline gas is a mixture

composed of approximately 98% methane and ethane

with the other 2% being hydrocarbons such as propane

and butane, nitrogen, carbon dioxide, and water vapor.

"Dry" means that is free of liquid hydrocarbons such as

gasoline, but NOT that it is free of water vapor.

Field Gas

The composition of

Field natural gas

varies considerably

by region and continent. Careful analysis is necessary

prior to using field natural gas in an engine because in

can contain heavier hydrocarbon gases which may require

derating of the output of the engine. Field natural gas

may also contain other contaminants such as sulfur.

Liquid Petroleum Gas (LPG)

Liquid Petroleum Gas is available in two grades,

commercial and special duty. Commercial propane is

used where high volatility is required. Special duty

propane (also called HD5) is a mixture of 95% propane

and other gases such as butane that allows better engine

performance due to the reduction pre-ignition due to

reduced volatility. Special duty propane fuel should meet

the ASTM D 1835 specifications for special duty propane.

BTU Content

The total BTU content of the fuel will determine the rating of

the generator set when using fuel of a specific compostion.

If any component of the fuel has more than the specific

value allowed, derating will be required. Consult MQ Power

for fuel derating instructions.

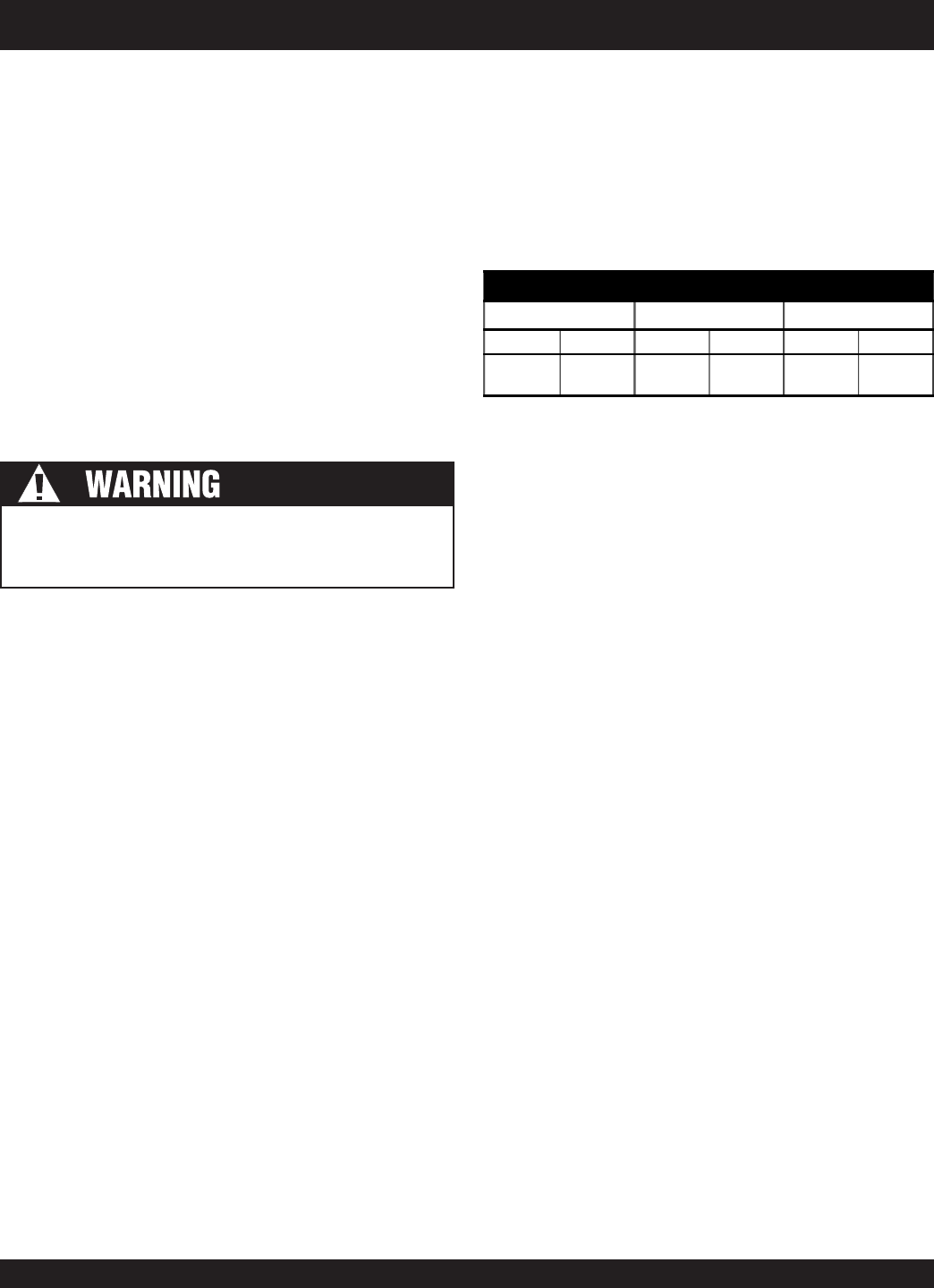

TABLE 11. TYPICAL BTU CONTENT OF GASEOUS FUEL

DRY PIPELINE GAS FIELD GAS LPG

LHV HHV LHV HHV LHV HHV

936

BTU/ft

3

1,038

BTU/ft

3

1,203

BTU/ft

3

1,325

BTU/ft

3

2,353

BTU/ft

3

2,557

BTU/ft

3

Failure to meet the minimum requirements in these areas will

result in the inability of the generator set to operate or carry

rated load and will induce poor performance.