HDA-SERIES WALK-BEHIND TROWEL — OPERATION AND PARTS MANUAL — REV. #9 (07/02/10) — PAGE 33

Trowel Arm Adjustment

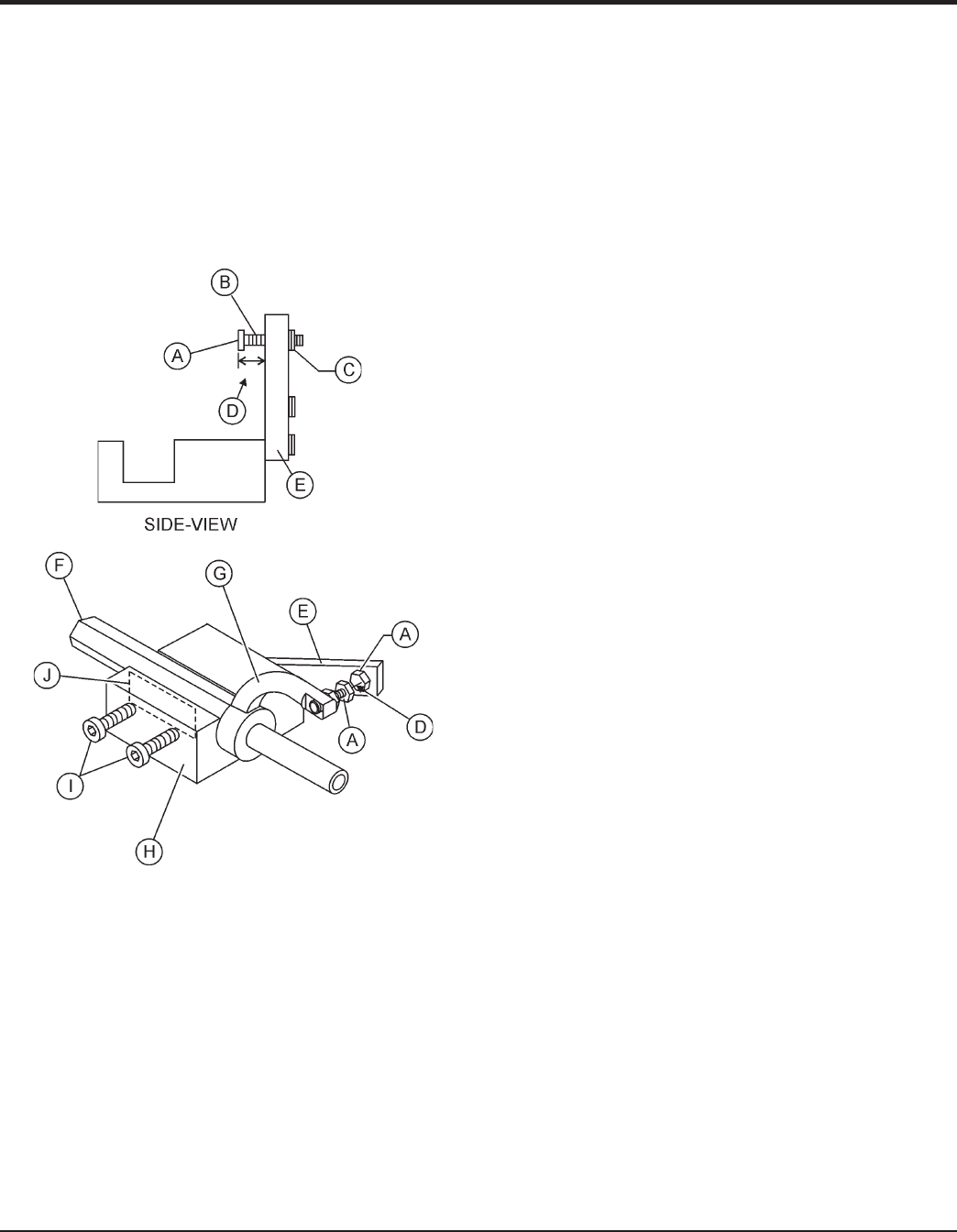

Shown in (Figure 45) is the adjustment fixture with a trowel arm

inserted. As each trowel arm is locked into the fixture, the arm bolt

is adjusted to where it contacts a stop on the fixture. This will

consistently adjust all of the trowel arms, keeping the finisher as

flat and evenly pitched as possible.

1. Locate the trowel arm adjustment tool P/N 1817. Set the

adjustment tool for a clockwise blade rotation, meaning the

fixture arm is in the "UP" position.

Figure 45. Trowel Arm Adjustment Tool

MAINTENANCE

3. Unscrew the locking bolts on the adjustment tool, and place

the trowel arm into the adjustment fixture channel (Figure 45).

A

thin shim

may be required to cover the blade holes on the

trowel arm. Make sure to align the trowel adjustment bolt with

the fixture adjustment bolt.

4. Using an allen wrench, tighten the locking bolts on the

adjustment tool and securely lock the trowel arm in place.

5. Loosen the locking nut on the trowel arm lever, then turn the

trowel arm adjusting bolt until it barely touches (.010") the

adjusting bolt on the fixture.

6. After the correct adjustment has been made, tighten lock nut

on trowel arm lever to lock in place.

7. Loosen locking bolts on adjustment fixture, and remove

trowel arm from fixture.

8. Repeat steps 2-7 for the remaining trowel arms.

A. Adjustment Bolt B. Adjust as in Step 2

C. Locking Nut D. Distance (.010 Inch)

E. Fixture Arm F. Arm

G. Trowel Arm Lever H. Fixture P/N 1817

I. Locking Bolts J. Shim

Re-Assembly

1. Clean and examine the upper/lower wear plates and thrust

collar. Examine the entire spider assembly. Wire brush any

concrete or rust build-up. If any of the spider components are

found to be damaged or out of round, replace them.

2. Make sure that the bronze trowel arm bushing is not dam-

aged or out of round. Clean the bushing if necessary. If the

bronze bushing is damaged or worn, replace it.

3. Reinstall bronze bushing onto trowel arm.

4. Repeat steps 2 -3 for each trowel arm.

5. Make sure that the spring tensioner is in the correct position

to exert tension on the trowel arm.

6. Insert all trowel arms with levers into spider plate (with bronze

bushing already installed) using care to align grease hole on

bronze bushing with grease hole fitting on spider plate.

7. Lock trowel arms in place by tightening the hex head zerk

grease fitting and jam nut.

8. Re-install the blades back onto the trowel arms.

9. Install stabilizer ring onto spider assembly.

10. Reinstall lower wear plate,

thrust collar

and

upper wear

ring

in the

reverse order

that they were dis-assembled onto

the spider shaft. Make sure that there is little or no lateral

movement between the thrust collar and the spider shaft.

2. Adjust the adjustment bolt to fit the tallest adjustment screw,

then adjust the other arms to match.