PAGE 22 — HDA-SERIES WALK-BEHIND TROWEL— OPERATION AND PARTS MANUAL — REV. #9 (07/02/10)

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

NEVER operate the trowel

in a confined area or enclosed

area structure that does not

provide ample

free flow of

air

.

ALWAYS wear approved eye and hearing

protection before operating the trowel.

NEVER place hands or feet inside the guard

rings while the engine is running. ALWAYS shut

the engine down before performing any kind of

maintenance service on the trowel.

PRE-INSPECTION

It is recommended that the trowel's

safety stop switch

be used

to stop the engine after every use. Doing this will verify that the

switch is working properly and presents no danger to the operator.

Before Starting

1. Read safety instructions at the beginning of manual.

2. Clean the

trowel

, removing dirt and dust, particularly the

engine cooling air inlet, carburetor and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty, replace

air filter with a new one as required.

4. Check carburetor for external dirt and dust. Clean with dry

compressed air.

5. Check fastening nuts and bolts for tightness.

Engine Oil Check

1. To check the engine oil level, place the trowel on secure level

ground with the engine stopped.

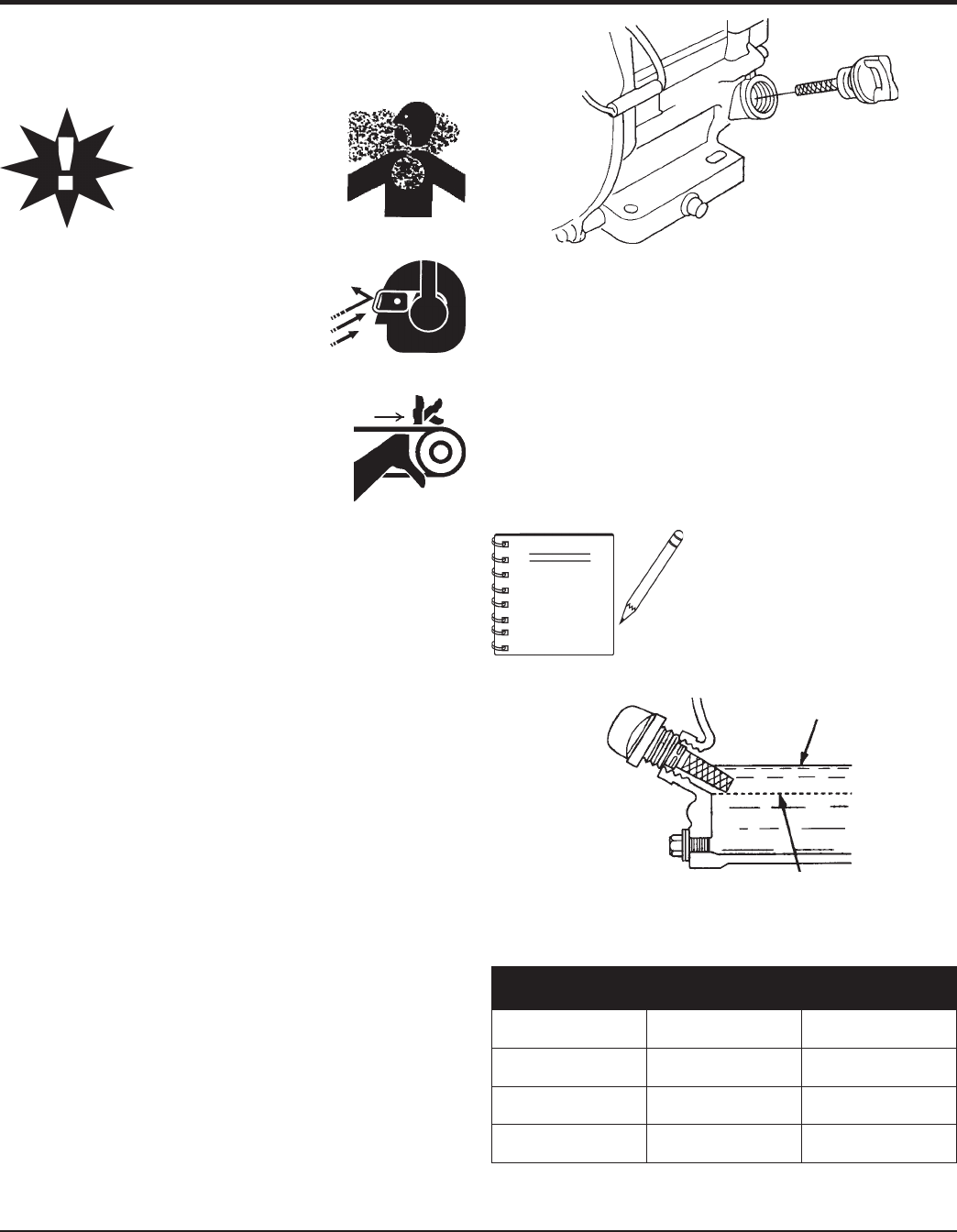

2. Remove the filler dipstick from the engine oil filler hole

(Figure 16) and wipe it clean.

Figure 16. Engine Oil Dipstick (Removal)

3. Insert and remove the dipstick without screwing it into the filler

neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 17), fill to the edge of the oil filler

hole with the recommended oil type (Table 3). Maximum oil

capacity is 1.16 US Qt. (1.1 liters).

Figure 17. Engine Oil Dipstick (Oil Level)

Reference manufacturer engine

manual for specific servicing

instructions.

NOTE

epyTliO.3elbaT

nosaeS erutarepmeT epyTliO

remmuS rehgiHroC°52 03-W01EAS

llaF/gnirpS C°01~C°52 02/03-W01EAS

retniW rewoLroC°0 01-W01EAS

PRE-INSPECTION