PAGE 62 — DCA-220SSJ— OPERATION AND PARTS MANUAL — REV. #1 (03/22/07)

Tires/Wheels/Lug Nuts

Tires and wheels are a very important and critical

components of the trailer. When specifying or replacing the

trailer wheels it is important the wheels, tires, and axle are

properly matched.

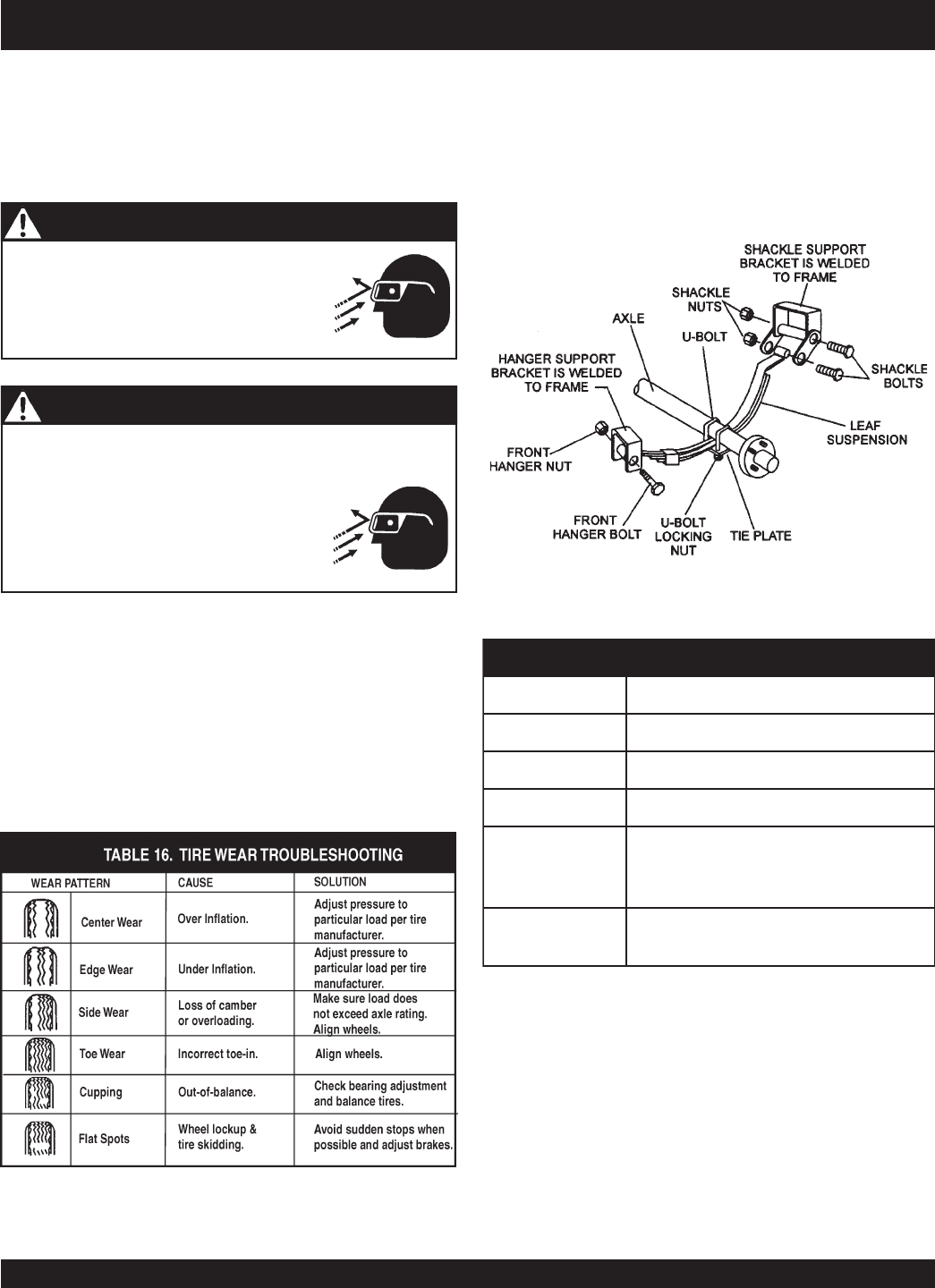

Tire Wear/Inflation

Tire inflation pressure is the most important factor in tire life.

Pressure should be checked cold before operation DO NOT

bleed air from tires when they are

hot!

. Check inflation

pressure weekly during use to insure the maximum tire life

and tread wear.

Table 16 (Tire Wear Troubleshooting) will help pinpoint the

causes and solutions of tire wear problems.

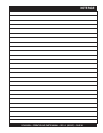

Suspension

The

leaf suspension

springs and associated components

(Figure 61) should be visually inspected every 6,000 miles

for signs of excessive wear, elongation of bolt holes, and

loosening of fasteners. Replace all damaged parts

(suspension) immediately. Torqued suspension components

as detailed in Table 17.

Figure 61. Major Suspension Components

DCA-220SSJ — MAINTENANCE (TRAILER)

DO NOT attempt to repair or modify a wheel. DO NOT

install in inner tube to correct a leak through the rim. If the

rim is cracked, the air pressure in the inner

tube may cause pieces of the rim to

explode (break off) with great force and

cause serious eye or bodily injury.

CAUTION - REPAIRING TRAILER WHEELS

ALWAYS

wear safety glasses when

removing or installing force fitted parts.

Failure to comply may result in serious

injury.

CAUTION - EYESIGHT HAZARD

stnemeriuqeReuqroTnoisnepsuS.71elbaT

metI ).sbL-.tF(euqroT

TLOB-U"8/353-XAM03-NIM

TLOB-U"61/706-XAM54-NIM

TLOB-U"2/106-XAM54-NIM

SHACKLE BOLT

SPRING EYE BOLT

SNUG FIT ONLY

.

PARTS MUST ROTATE FREELY

.

LOCKING NUTS OR COTTER PINS ARE PROVIDED

TO RETAIN NUT

-

BOLT ASSEMBLY

.

SHOULDER TYPE

SHACKLE BOLT

05-XAM03-NIM