PAGE 36 — DCA-100SSVU— OPERATION AND PARTS MANUAL — REV. #0 (11/05/07)

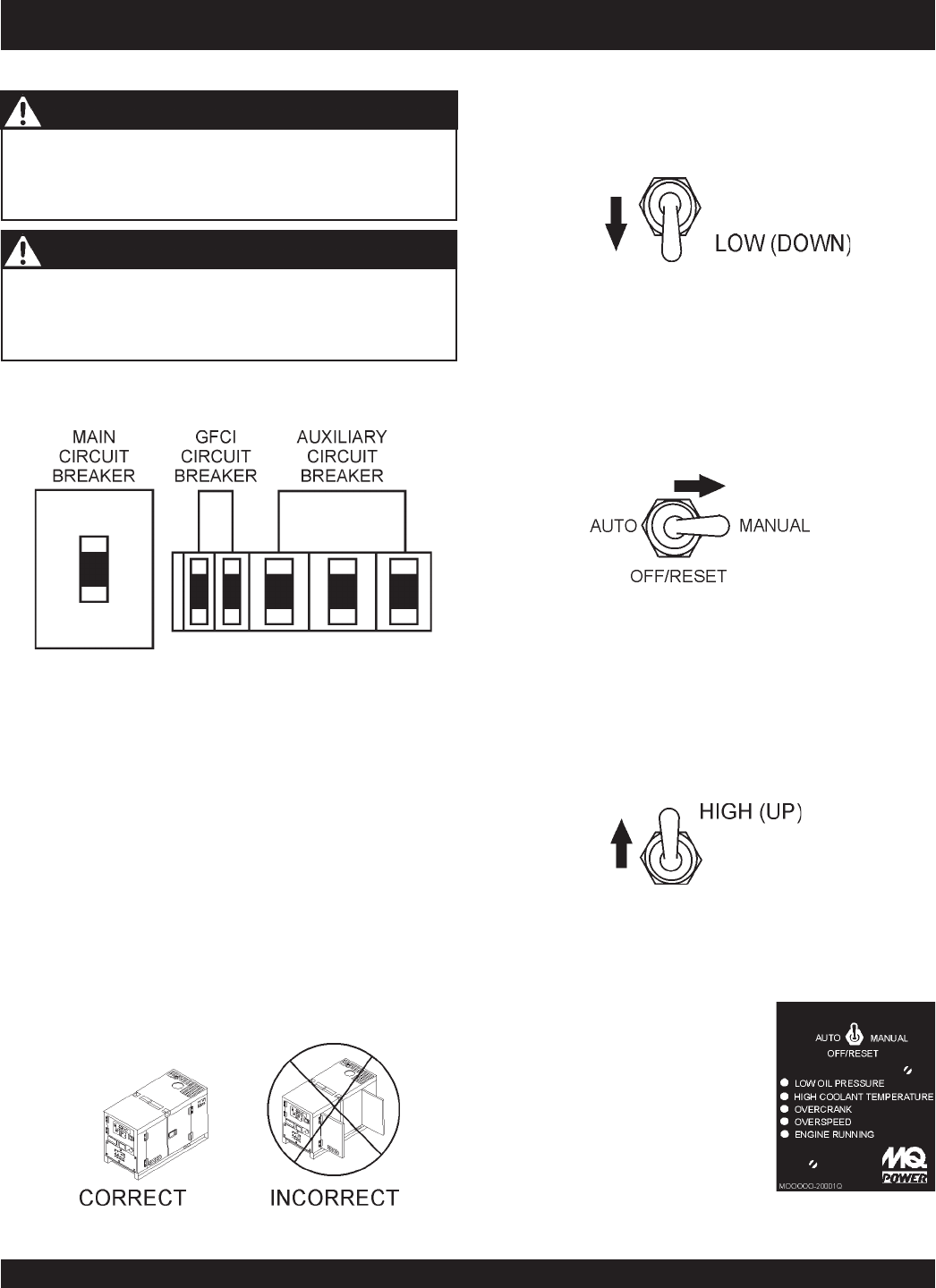

4. Verify that the Engine Running

status LED on the MPEC unit

(Figure 44) is ON (lit) after the

engine has been started.

Figure 44. Engine Running LED (ON)

Manual Start-up

Procedure

Figure 42. MPEC Control Switch

(Manual Position)

DCA-100SSVU — GENERATOR START-UP PROCEDURE (MANUAL)

The engine's exhaust contains harmful emissions.

ALWAYS have adequate ventilation when operating

.

Direct exhaust away from nearby personnel.

Before Starting

Figure 39. Engine Enclosure Doors

1. Place the

main, G.F.C.I.,

and

aux.

circuit breakers

(Figure 38) in the OFF position prior to starting the engine.

Figure 38. Main, Aux. and GFCI

Circuit Breakers (OFF)

2. Make sure the the

voltage change-over board

has

been configured for the desired output voltage.

3. Connect the load to the

receptacles

or

the

output

terminal lugs

as shown in Figure 13. These load

connection points can be found on the output terminal

panel and the output terminal panel’s hard wire hookup

panel.

4. The output terminal lugs are protected by a plastic cover.

Remove this cover to gain access to the terminals.

Tighten terminal nuts securely to prevent load wires from

slipping out.

5. Close all engine enclosure doors (Figure 39).

CAUTION - LETHAL EXHAUST HAZARD

3. Once the engine starts, let it engine run for 1-2 minutes.

Listen for any abnormal noises. If any abnormalities

exists shutdown the engine and correct the problem.

If the engine is running smoothly, place the engine

speed switch (Figure 43) in the “

HIGH

” (up) position.

2. Once the engine glow plugs have been warmed, place

the

MPEC Control Switch

in the MANUAL position to

start the engine (Figure 42).

Figure 41. Engine Speed Switch (Low)

Figure 43. Engine Speed Switch (High)

NEVER!

manually start the engine with the

main

,

GFCI

or

auxiliary

circuit breakers in the ON (closed) position.

WARNING - STARTING THE GENERATOR

1. Place the engine speed switch (Figure 41) in the “

LOW

”

(down) position.