16” Bar 54 DL

6220-210816

18” Bar 60 DL

6220-210805

19

18

GUIDE BAR MAINTENANCE:

Most guide bar problems can be prevented merely by

keeping the chain saw well maintained.

Insufficient guide bar lubrication and operating the saw

with chain that is too tight will contribute to rapid bar wear.

To help minimize bar wear, the following guide bar

maintenance procedures are recommended.

BAR WEAR - Turn guide bar frequently at regular

intervals (for example, after 5 hours of use), to ensure

even wear on top and bottom of bar.

BAR GROOVES - Bar grooves (or rails which support and

carry the chain) should be cleaned if saw has been used

heavily or if saw chain appears dirty. Rails should always

be cleaned every time saw chain is removed.

OIL PASSAGES - Oil passages on the bar should be

cleaned to ensure proper lubrication of the bar and chain

during operation.

NOTE: The condition of the oil passages can be easily

checked. If the passages are clear, the chain will

automatically give off a spray of oil within

seconds of starting the saw. Your saw is

equipped with an automatic oiler system.

CHAIN MAINTENANCE

Chain Tension

Check the chain tension frequently and adjust as often as

necessary to keep the chain snug on the bar, but loose

enough to be pulled around by hand.

Breaking in a New Saw Chain

A new chain and bar will need chain readjustment after

as few as 5 cuts. This is normal during the break-in

period, and the interval between future adjustments will

begin to lengthen quickly.

Chain Lubrication

Always make sure the automatic oiler system is working

properly. Keep the oil tank filled with Genuine Factory

Parts Chain, Bar and Sprocket Oil.

Adequate lubrication of the bar and chain during cutting

operations is essential to minimize friction with the guide bar.

Never starve the bar and chain of lubricating oil. Running

the saw dry or with too little oil will decrease cutting

efficiency, shorten saw chain life, cause rapid dulling of

chain, and lead to excessive wear of bar from

overheating. Too little oil is evidenced by smoke or bar

discoloration.

Chain Sharpening

Chain sharpening requires special tools to ensure that

cutters are sharpened at the correct angle and depth. For

the inexperienced chain saw user, we recommend that

the saw chain be professionally sharpened by the

nearest Authorized Service Center. If you feel

comfortable sharpening your own saw chain, special

tools are available from your Authorized Service Center.

MAINTENANCE AND REPAIR INSTRUCTIONS

Never have more

than 3 links

removed from a loop of chain. This could

cause damage to the sprocket.

WARNING:

CHAIN REPLACEMENT INFORMATION

There may be other quality equivalent replacement

components for achieving kickback protection.

INERTIA CHAIN BRAKE

®

ACTION

NOTE: THIS SAW IS EQUIPPED WITH AN INERTIA

CHAIN BRAKE. IF THE SAW KICKS BACK

WHILE IN USE, THE INERTIA OF THE MOVING

SAW WILL ACTIVATE THE BRAKE. A BRAKE

BAND AROUND THE CLUTCH DRUM

ACTIVATES AND STOPS THE MOVING CHAIN.

CHAIN BRAKE

®

OPERATIONAL TEST

Test the Chain Brake

®

periodically to ensure proper

function.

Perform a Chain Brake

®

test prior to initial cutting,

following extensive cutting, and definitely following any

Chain Brake

®

service. Test the Chain Brake:

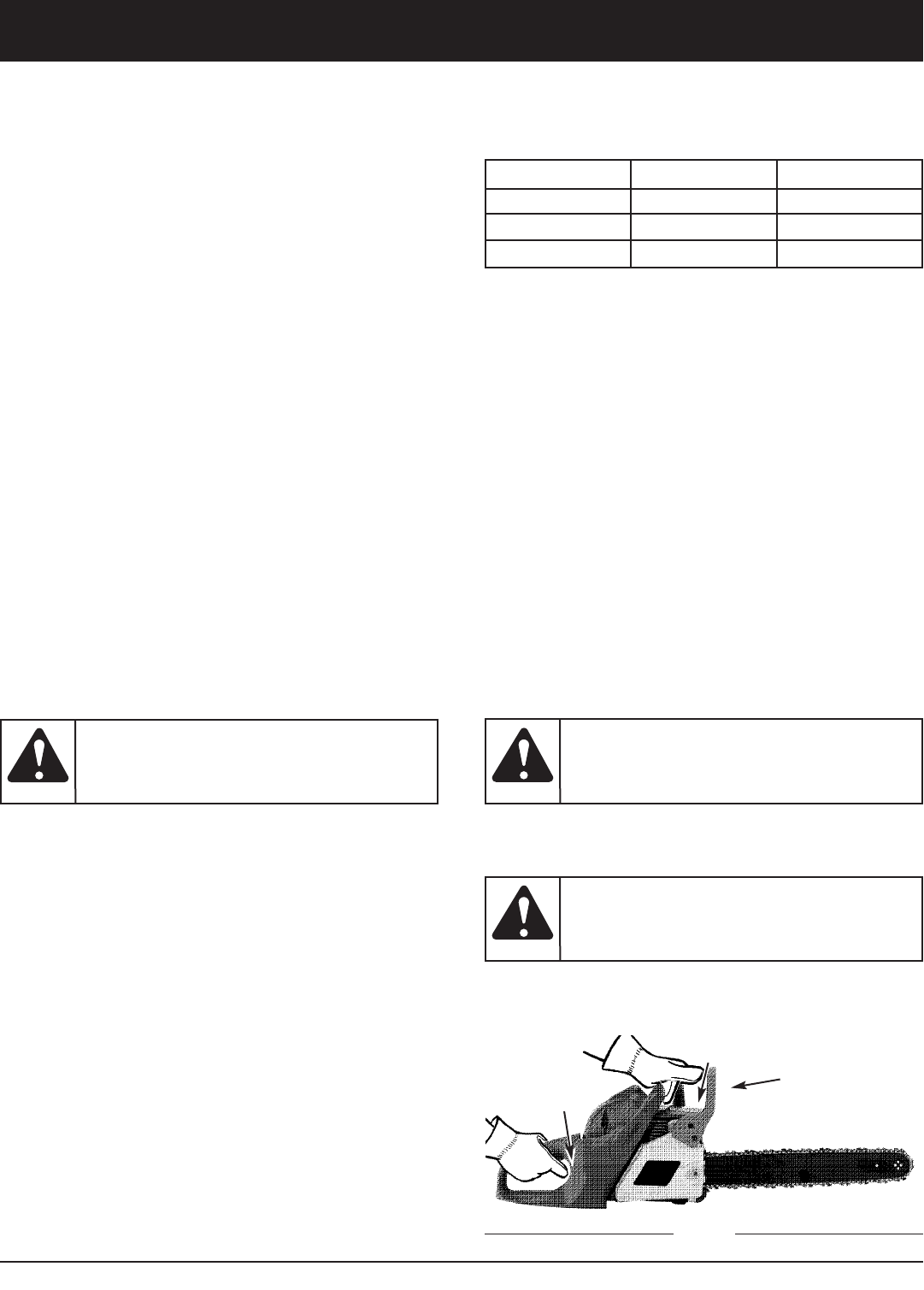

1. Place saw on a clear, firm, flat surface.

2. Start engine.

3. Grasp the rear handle (A) with your right hand (Fig. 33).

4. With your left hand, hold the front handle (B) [not

Chain Brake

®

lever (C)] firmly (Fig. 33).

5. Squeeze the throttle trigger to 1/3 throttle, then

immediately activate the Chain Brake

®

lever (C) (Fig. 33).

6. Chain should stop abruptly. When it does,

immediately release the throttle trigger.

A

C

B

Activate the Chain

Brake

®

slowly and

deliberately. Keep the chain from touching

anything; don’t let the saw tip forward.

WARNING:

If chain does not

stop, tur

n engine of

f

and take your unit to the nearest Authorized

Service Center for service.

WARNING:

Fig. 33

7. If Chain Brake

®

functions properly, turn the engine off

and return the Chain Brake

®

to the DISENGAGED

position.

Bar Length Drive Links

Part Number

14” Bar 49 DL

6220-210803

MAINTENANCE AND REPAIR INSTRUCTIONS

STORING A CHAIN SAW

Storing a chain saw for longer than 30 days requires

storage maintenance. Unless the storage instructions are

followed, fuel remaining in the carburetor will evaporate,

leaving gum-like deposits. This could lead to difficult

starting and result in costly repairs.

1. Remove the fuel tank cap slowly to release any

pressure in tank. Carefully drain the fuel tank.

2. Start the engine and let it run until the unit stops to

remove fuel from carburetor.

3. Allow the engine to cool (approx. 5 minutes).

4. Using a spark plug wrench, remove the spark plug.

5. Pour 1 teaspoon of clean 2-cycle oil into the

combustion chamber. Pull starter rope slowly several

times to coat internal components. Replace spark

plug (Fig. 31).

NOTE: Store the unit in a dry place and away from

possible sources of ignition such as a furnace,

gas hot water heater, gas dryer, etc.

Fig. 31

REMOVING A UNIT FROM STORAGE

1. Remove spark plug.

2. Pull starter rope briskly to clear excess oil from

combustion chamber.

3. Clean and gap spark plug or install a new spark plug

with proper gap.

4. Prepare unit for operation.

5. Fill fuel tank with proper fuel / oil mixture. See Oil

and Fuel Information.

Never stor

e a chain

saw for longer than

30 days without performing the following

procedures.

CAUTION:

Sprocket Tip Lubrication

The Lube Gun (optional) is recommended for applying

grease to the guide bar sprocket tip. The Lube Gun is

equipped with a needle nose tip which is necessary for

the efficient application of grease to the sprocket tip.

The spr

ocket tip on

your new saw has

been pre-lubricated at the factory. Failure to

lubricate the guide bar sprocket tip as

explained below will result in poor

performance and seizure, voiding the

manufacturer’s warranty.

Lubrication of the sprocket tip is

recommended after 10 hours of use or

once a week, which ever occurs first.

Always thoroughly clean guide bar sprocket

tip before lubrication.

CAUTION:

Fig. 32

To lubricate the sprocket tip:

1. Move the STOP switch down.

NOTE: It is not necessary to remove the saw chain to

lubricate the guide bar sprocket tip. Lubrication

can be done on the job.

2. Clean the guide bar sprocket tip.

3. Using the Lube Gun (optional), insert tip of lube gun

into the lubrication hole and inject grease until it

appears at outside edge of sprocket tip (Fig. 32).

4.

Rotate saw chain by hand. Repeat lubrication procedure

until the entire sprocket tip has been greased.

SAW CHAIN / BAR LUBRICATION

Adequate lubrication of the saw chain is essential at all

times to minimize friction with the guide bar.

Never starve the bar and chain of oil. Running the saw

with too little oil will decrease cutting efficiency, shorten

saw chain life, cause rapid dulling of chain, and cause

excessive wear of bar from overheating. Too little oil is

evidenced by smoke, bar discoloration or pitch build-up.

NOTE: Saw chain stretches during use, particularly when

it is new, and it will occasionally be necessary to

adjust and tighten it. New chain will require

adjustment after about 5 minutes of operation.

AUTOMATIC OILER

Your chain saw is equipped with an automatic gear driven

oiler system. The oiler automatically delivers the proper

amount of oil to the bar and chain. As the engine speed

increases, so does the oil flow to the bar pad. There is no

flow adjustment. The oil reservoir will run out at

approximately the same time as the fuel supply runs out.

GUIDE BAR MAINTENANCE

Frequent lubrication of the guide bar (railed bar which

supports and carries the saw chain) sprocket tip is

required. Proper maintenance of the guide bar, as

explained in this section, is essential to keep your saw in

good working condition.