PRE-OPERATION

WARNING: BEFORE OPERATING, READ THIS OWNERS MANUAL COMPLETELY. PAY

PARTICULAR ATTENTION TO THE “SAFETY PRECAUTION” AND “SAFETY FIRST” PAGES. READ ALL

SAFETY MESSAGES HIGHLIGHTED BY “SAFETY ALERT SYMBOLS” THROUGHOUT THE MANUAL.

This spreader must be operated with a 1000 RPM PTO.

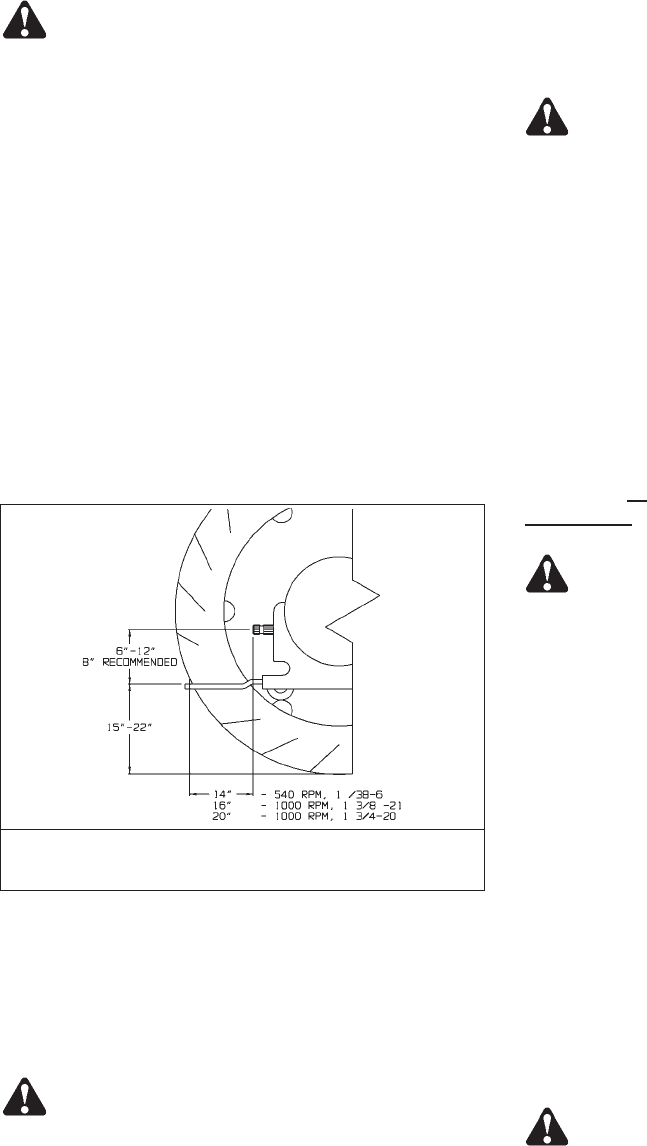

The hitch of the spreader is designed for a standard

tractor drawbar. Adjust the drawbar at 15 to 22 inches

above the ground. Extend or shorten the drawbar so

horizontal distance from end of tractor PTO shaft to cen

-

ter of the hitch pin hole is 20” (1 3/4-20), 16” (1 3/8-21).

Secure the drawbar so that the hitch pin hole is located

directly below the PTO drive line. See figure 1 for loca

-

tion of standard measurements.

An improperly located hitch point may cause damage to

the universal joints of the PTO drive shaft. Conforming

to the standard 16" or 20” drawbar & PTO relationship

will ensure that the PTO drive shaft will not become

over-extended.

WITH INITIAL HOOK-UP TO YOUR NEW MEYER

SPREADER TEST PTO TRAVEL BY TURNING

EQUIPMENT IN BOTH DIRECTIONS OBSERVING

THE MINIMUM AND MAXIMUM TRAVEL DIMEN

-

SIONS AS SHOWN PER DRAWING ON FIGURE 5,

PAGE 15.

DANGER: DO NOT OPERATE WITHOUT PTO

GUARD ON SPREADER AND ON TRACTOR. MAIN

-

TAIN PTO DRIVE SHAFT GUARD TUBES IN OPER

-

ATING CONDITION. REPLACE THEM IF DAMAGED

AND NOT TURNING FREELY. FAILURE TO HEED

MAY RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

WARNING: INSPECT REGULARLY THAT ALL

CONNECTIONS AND BOLTS ARE TIGHT AND SE

-

CURE BEFORE OPERATING. FAILURE TO HEED MAY

RESULT IN SERIOUS PERSONALINJURY OR DEATH.

Check for proper assembly and adjustment and make

sure that all bolts are tightened. Securely retighten after

a few hours ofoperation, as bolts can loosen up onnew

machinery. Check wheel lug nuts upon delivery and pe

-

riodically thereafter. Lug nuts should be tightened at

250-265 ft./lbs. of torque. Check the tires and inflate to

the recommended pressure. See chart on page 60.

Inspect all adjustments on the spreader to be sure they

are proper and to provide maximum performance. Lubri

-

cate the spreader completely if it is required and check

the level of oil

in the right rear corner gear box, and the

gear grease

in the expeller gear boxes.

WARNING: DO NOT OPERATE WITHOUT

ALL SHIELDS, GUARDS AND COVERS INSTALLED.

FAILURE TO HEED MAY RESULT IN SERIOUS PER-

SONAL INJURY OR DEATH.

Fasten the spreader hitch to the tractor drawbar with a

hitch pin that cannot bounce out. Use a 1-5/16” to 1-3/8”

diameter hitch pin to pull spreader.

Remove the weight from the jack (jack is not to be used

when spreader is loaded). Remove the jack from round

mount tube and move to the transport storage tube on

the front of the spreader drive enclosure. Store in a hori

-

zontal position.

Before operation and after hitching the tractor to the

spreader, connect the PTO drive shaft to the tractor.

Slide spring loaded locking collar on PTO yoke rearward,

and slide yoke onto the tractor PTO shaft. Release spring

loaded collar. Be sure pins fall into groove of tractor PTO

shaft and collar snaps forward into locking position.

CAUTION: DO NOT USE A STEEL HAMMER

TO AID IN JOINING PTO PARTS.

Route hydraulic hoses through the hose support rod

which is mounted to the hitch frame, figure 2. Connect

the hydraulic hoses for the flow control rear gate to the

tractor’s double acting valve hydraulic system. Move the

tractor hydraulic controls to observe proper flow gate

Model 8720/8865 -8-

FIGURE 1. TRACTOR DRAWBAR & PTO

SPECIFICATION