LUBRICATION

WARNING: DISCONNECT PTO DRIVE SHAFT AND HYDRAULIC HOSES (RELIEVE HYDRAULIC

PRESSURE) BEFORE CLEANING, ADJUSTING, LUBRICATING OR SERVICING THIS SPREADER. FAILURE TO

HEED MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

DAILY LUBRICATION (every 8-12 loads

)

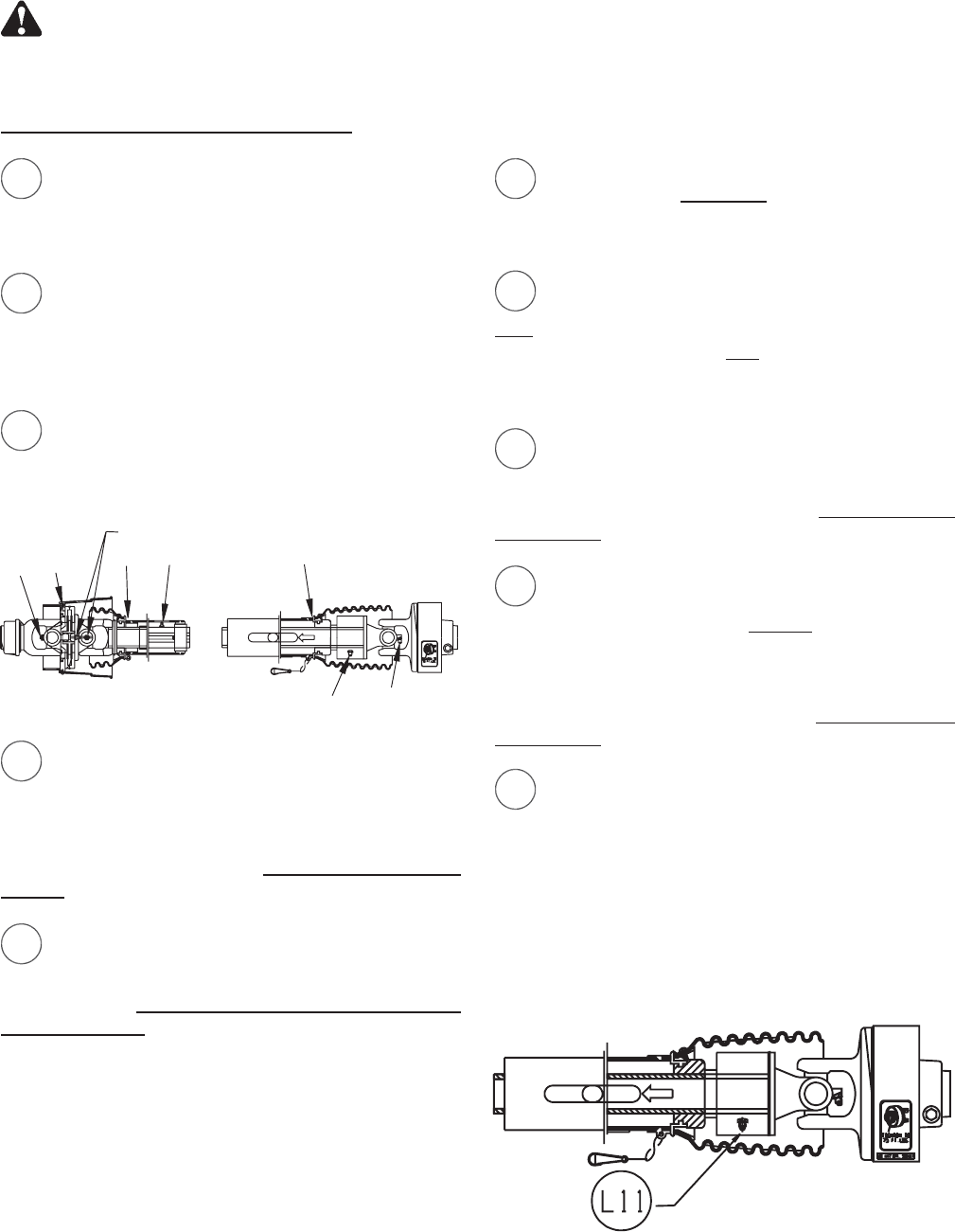

Grease (2) rear spinner lower bearings. These

bearings are grease line fitted to the LR frame channel

of the spreader.

Oil (6) roller chain drives with automatic oiler at the

front of spreader with clean 30-weight oil. The roller

chains are accessible by opening the front steel shield

-

ing cover.

Grease PTO Drive line (9) places with Lithium

grease every 8 hours.

Grease (7) bearings supporting the three large

jack shaft reduction sprocket weldments, and the third

auger drive shaft on thefront drive. The zerks are acces

-

sible by the right front side grease bank and through the

access holes in front plate. Be careful not to over

grease.

Grease (2) auger shaft bearings. These bearings

are grease line fitted to the LF and RF frame channels of

the spreader. Over greasing is not possible. 10-15

pumps minimum.

IMPORTANT: Check regularly for any observable lubri

-

cant leakage of the (3) gearboxes at the rear of the

spreader. See L12 & L14 under Monthly Lubrication

WEEKLY LUBRICATION (every 25-30 loads)

Grease (3) PTO input shaft

bearings. These bear

-

ings are grease line fitted to the RF frame channel and

the front bearing channel of the spreader.

Grease (5) bearings on the RH side line shaft. The

front

bearing is zerk accessible through the RF steel

shielding. The remaining rear

bearings are located

along the RH side of the spreadertank, zerks accessible

through the steel shielding.

Grease (2) tandem wing pivots. Effectively grease

by jacking up the spreader to relieve pressure points on

the pivot shaft and tandem wing collar. Over greasing is

not possible.

Grease (2) flow control rear gate slide guides.

With the flow control rear gate opened

, grease the slide

guides from top side. Allow grease to lubricate flow con-

trol rear gate ends and slide guide surfaces. In freezing

weather dump used motor oil down each slide guide

once a week or more often if needed. Over greasing is

not possible.

Grease (1) integral overrunning clutch at rear of

the PTO drive line. The zerk is on the yoke of the cut out

clutch. Use Shell Super Duty or an equivalent lithium

grease.

Model 8720/8865 -20-

IMPORTANT: GREASE2FITTINGSDAILY

L1

L2

L3

L4

L5

L6

L7

L8

L10

L11