24

C

D

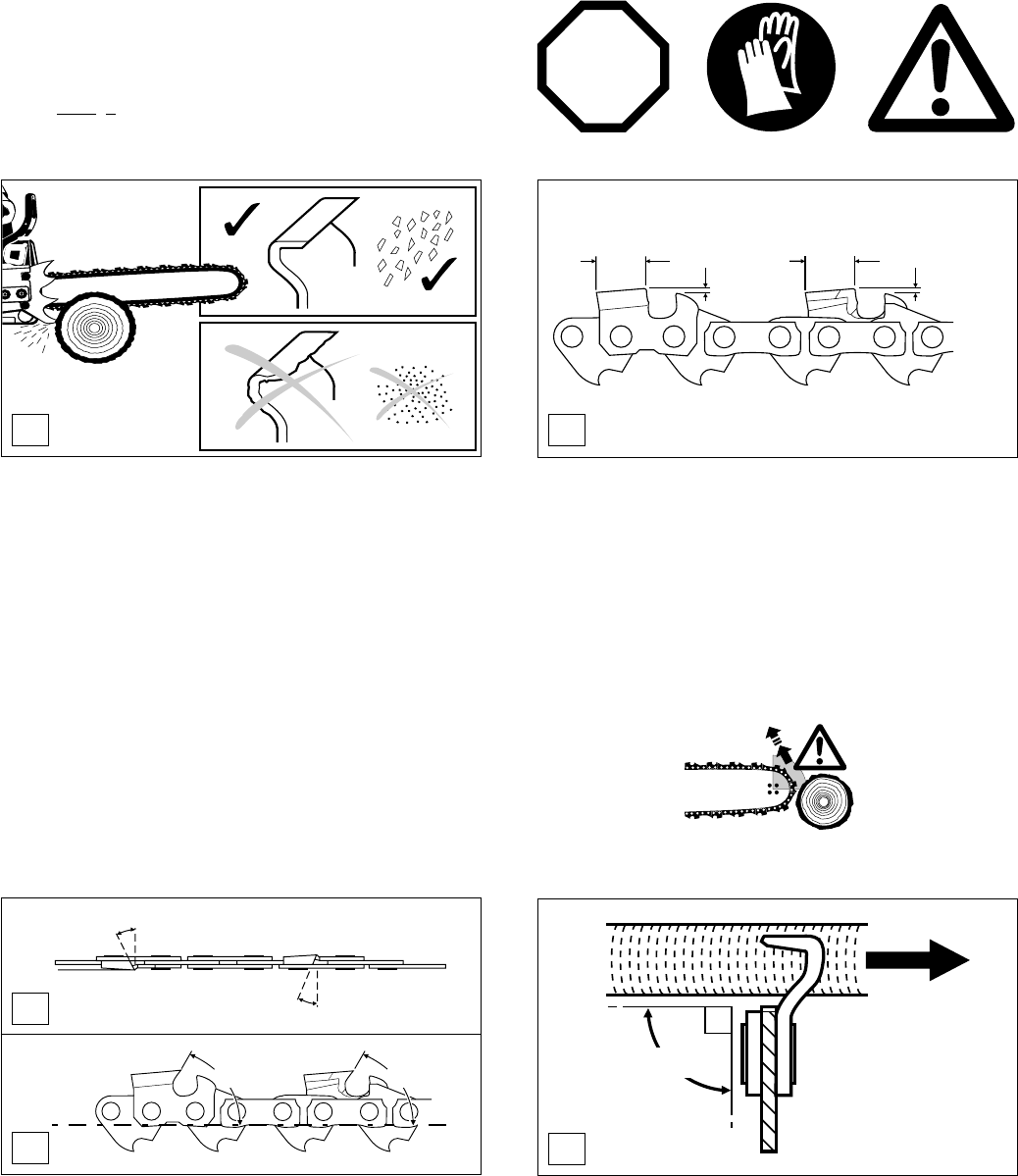

Files and how to work with them

- Sharpen using a special file holder with a saw chain round

file. Normal round files are not appropriate for this work.

See "Accessories" for the order number.

- File the first cutter half with a 7/32" (5,5 mm) dia. round file,

then switch to a 3/16" (4,8 mm) dia. file.

- The file should cut only when pushed forwards (arrow).

Lift the file when leading it backwards.

- First sharpen the shortest cutter. The length of this cutter is

then the nominal value for all other cutters of the chain.

- Replaced cutters must be exactly adopted to the shape of

the other cutters. This is also true for the depth gauges.

- Always guide the file horizontally (90

o

to the guide bar).

- The sharpening angle of 25

o

must be equal for all cutters.

Different angles result in a roughly, irregularly running

chain, increase wear and tear and cause chain ruptures.

- The front rake of 60

o

depends on the cut depth of the round

file. If the file to be used is guided correctly, the correct front

rake results automatically.

MAINTENANCE

Sharpening the saw chain

CAUTION: Before doing any work on the guide bar or

chain,

always switch off the engine and pull the plug cap

off the spark plug (see "Replacing the spark plug"). Al-

ways wear protective gloves!

The chain needs sharpening when:

- The sawdust produced when sawing humid wood looks like

wood flour.

- The chain penetrates the wood only under great pressure.

- The cutting edge is visibly damaged.

- The sawing device is pulled to the left or right when sawing.

This is caused by an unequal sharpening of the chain.

Important: Sharpen regularly, but only slightly.

Generally 2-3 touches are enough.

Have the chain resharpened in a service center when you

have already sharpened it yourself several times.

Characteristics of a correctly sharpened chain (type 099):

- All cutters must be of the same length (=). Cutters with

different lengths result in a rough running of the chain and

produce cracks in the chain.

- The best cutting results are achieved with a depth limiter

distance of 0.65 mm (.025"). The distance between the

depth limiter and the cutting edge determines the depth of

the cut.

CAUTION:

If the distance is too wide, the risk of kickbacks

increases.

=

90°

25°

25°

=

0,65 mm

(.025")

A

60°

60°

E

B

STOP