28

Section 3: Operating Procedures

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

12/16/08

Land Pride

Table of Contents

Cutting Operation

!

WARNING

The following operating procedures must be carefully read and

fully understood. You are the tractor operator and are therefore

responsible for the safe operation of this unit. All other persons

must be cleared of the area. Cutter operation must be stopped

when in the vicinity of other persons.

!

CAUTION

Do not over speed PTO or machine damage may result.

The RCP2660 & RCP3060 operates at 540 RPM and

RCPM2660 & RCPM3060 operates at 1000 RPM.

!

DANGER

PTO shields must be secured in place when operating to avoid

injury or death from entanglement in rotating drivelines.

!

WARNING

The Parallel Arm Rotary Cutter is designed to cut grass and

brush up to 2” in diameter. Using this cutter for another type

of work can damage the drive components, deck and support

frame.

!

WARNING

Do not operate this cutter under any terrain conditions that

would place tractor at an angle exceeding 30 degrees either

front-to-rear or left-to-right. Make sure adequate ballast

weights are provided on both the front of tractor and left of

tractor and left hand side of cutter to assure tractor stability.

!

DANGER

Rotary Cutters have the ability to discharge objects at high

speeds. Front & rear deck safety shields are required!

!

DANGER

Do not use deck as a fan. Cutting blades are not properly

designed or guarded for this use. Using deck as a fan can

result in injury and/or death.

!

DANGER

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

IMPORTANT: Avoid catching hydraulic hoses on

brush, post, stumps, and other protrusions that

could damage and/or break them.

1. After attaching cutter to the tractor, carefully raise and

lower the unit to ensure that the drawbar, tires, and

other equipment on the tractor do not contact cutter

frame or PTO driveline.

2. Remove and stow transport safety chain before

extending the arms or lowering the deck.

3. Adjust tractor lower 3-point arms such that PTO

driveline is approximately level.

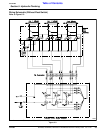

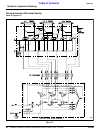

4. Skip to step step 5 if control stick is not included. If

control stick is included, read and fully understand

“Switch Functions” on page 19.

5. Extend parallel arms and deck cylinder as follows:

Deck without gauge wheels:

a. Starting with “ARM 1”, extend the two parallel arms

switching back-and-forth from “ARM 1” to “ARM 2”

until both arms are positioned as needed.

b. Extend “DECK” cylinder until deck is parallel to the

ground.

c. Adjust deck and parallel arms to locate cutter for

best operator visibility. Normally, this is with arms

extended out approximately 3/4 of full extension.

Deck with gauge wheels:

a. Make certain tractor control levers are set to center

detent position and if available, Float Switch on the

control stick is “OFF”.

b. Starting with “ARM 1”, extend the two parallel arms

switching back-and-forth from “ARM 1” to “ARM 2”

until both arms are positioned as needed.

c. Extend “DECK” cylinder until deck is resting on its

gauge wheels.

d. Switch “ARM 2” and “DECK” cylinders to float

position.

• Solenoid controlled cylinders:

Change Float Switch from “OFF” to “ON”.

• Tractor controlled levers:

Place “ARM 2" and “DECK” control levers in float

position.

e. Adjust ratchet jacks to raise or lower deck to

desired cutting height. See also “Deck Level

Adjustments” on page 26

f. Adjust “ARM 1” to locate cutter for best operator

visibility. Normally, this is with arms extended out

approximately 3/4 of full extension.

IMPORTANT: Do not exceed rated PTO speed of

the cutter. Excessive engine speed will cause

damage to the speed increaser and other power

train components.

IMPORTANT: Control stick must be kept out of the

rain during operation and when in storage. Never

use high pressure wash to clean the control stick.