20

Section 1: Assembly & Set-up

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

11/11/12

Table of Contents

Driveline Installation

!

DANGER

Do not engage tractor PTO while hooking-up and unhooking

driveline or while someone is standing near the driveline. A

person’s body and/or clothing can become entangled in the

driveline resulting in serious injury or death.

!

WARNING

To avoid serious injury or death:

• Do not use PTO adapters. A PTO adapter will increase strain

on the tractor’s PTO shaft resulting in possible damage to

shaft and driveline. It will also defeat the purpose of the

tractor’s master shield.

• Always disengage PTO, place tractor in park or set park

brake, shut tractor engine off, remove switch key, and wait for

blades to stop before dismounting from tractor.

• Make certain all driveline yokes are securely fastened at both

ends. A loose yoke can work free allowing the driveline to

rotate uncontrollably causing machine damage and bodily

injury or death to anyone nearby.

• Do not operate cutter above its rated PTO speed or machine

breakage may result.

The main driveline may be either constant velocity type

or conventional type. Pull-collar coupler and retaining

bolts are used to connect the driveline to the tractor and

implement gearbox, respectively.

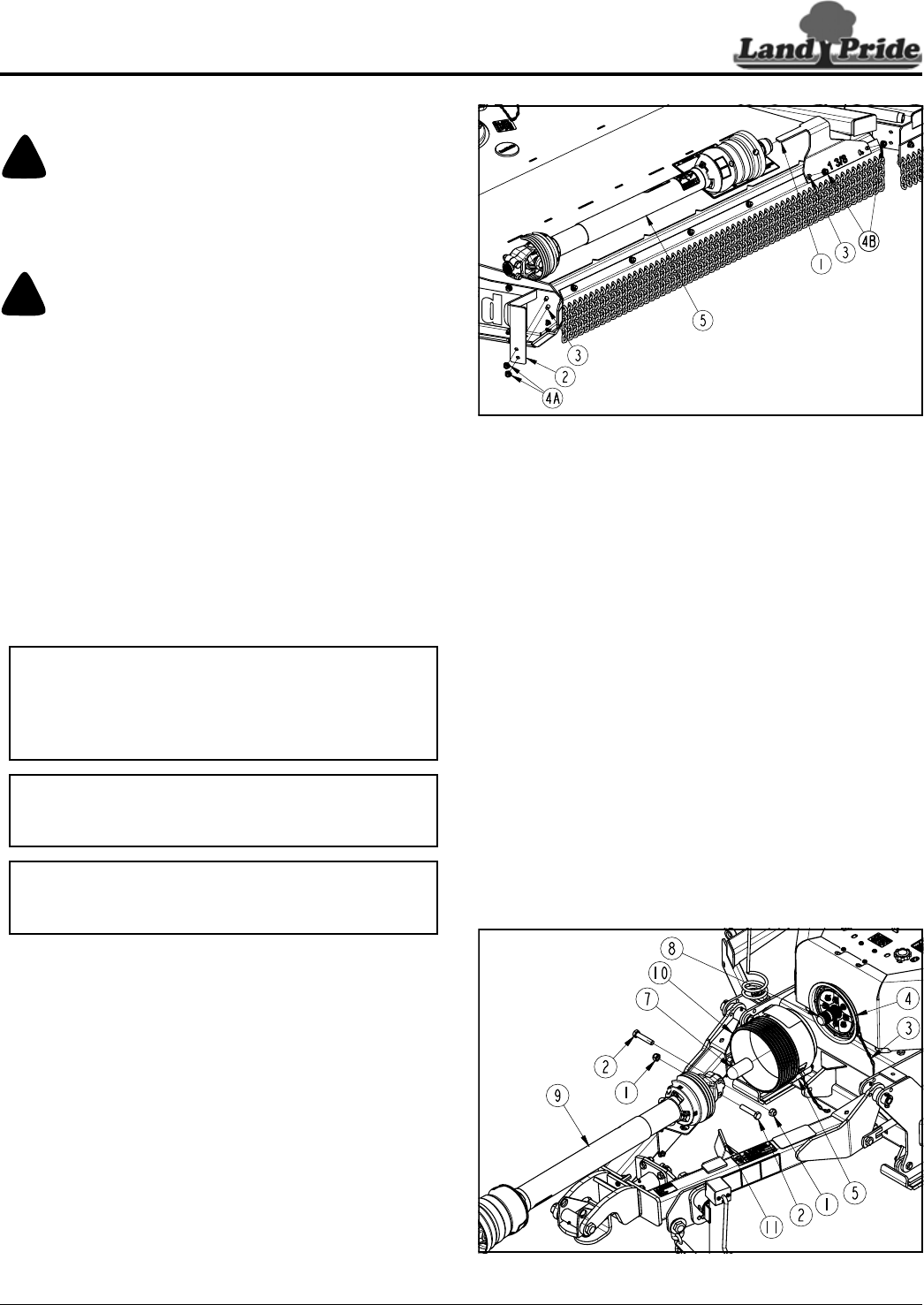

Refer to Figure 1-16:

1. Remove hex whiz nuts (#4A) and shipping

bracket (#2). Discard shipping bracket.

2. Slide driveline (#5) off end of shipping bracket (#1).

Set driveline aside for attaching to splitter box later.

3. Reattach hex whiz nuts (#4A) to carriage bolts (#3)

and tighten them to the correct torque.

4. Remove hex whiz nuts (#4B) and shipping

bracket (#1). Discard shipping bracket.

5. Reattach hex whiz nuts (#4B) to carriage bolts (#3)

and tighten them to the correct torque.

IMPORTANT: Do not attempt to operate a 540 rpm

driveline at 1,000 rpm or a 1,000 rpm driveline at 540

rpm. Many tractors provide both 540 and 1,000 rpm

PTO modes. Check your tractor’s manual to

determine its capabilities.

IMPORTANT: The driveline must be lubricated

before putting it into service. Refer to “Lubrication

Points” on page 49.

NOTE: Complete “Unfolding Wing Deck”

instructions on page 18 before removing driveline

from its shipping location.

Remove Main Driveline From Cutter

Figure 1-16

Refer to Figure 1-17:

6. Unsnap latches (#5) on both sides of gearbox

shield (#10) and remove shield.

7. Remove and discard rubber shaft protector (#7) from

splitter gearbox shaft (#8).

8. Remove locknuts (#1) and bolts (#2) from bolted

coupler end of driveline (#9).

9. Insert bolted coupler end of driveline (#9) through

gearbox shield (#10) and attach to gearbox input

shaft (#8) with removed bolts (#2) and locknuts (#1).

Tighten locknuts to the correct torque.

10. Collapse driveline (#9) by pushing tractor end of

driveline toward splitter gearbox (#8).

11. Rotate driveline hanger (#11) up and support

driveline (#9) on hanger. Final adjustments to hanger

will be made later after tractor hook-up.

12. Return gearbox shield (#10) to mounting plate (#4)

and secure with latches (#5).

13. Check safety chain (#3). Make sure it is latched to

mounting plate (#4) and gearbox shield (#10).

Driveline Installation

Figure 1-17

37810

37960