10

MAINTENANCE & SERVICE

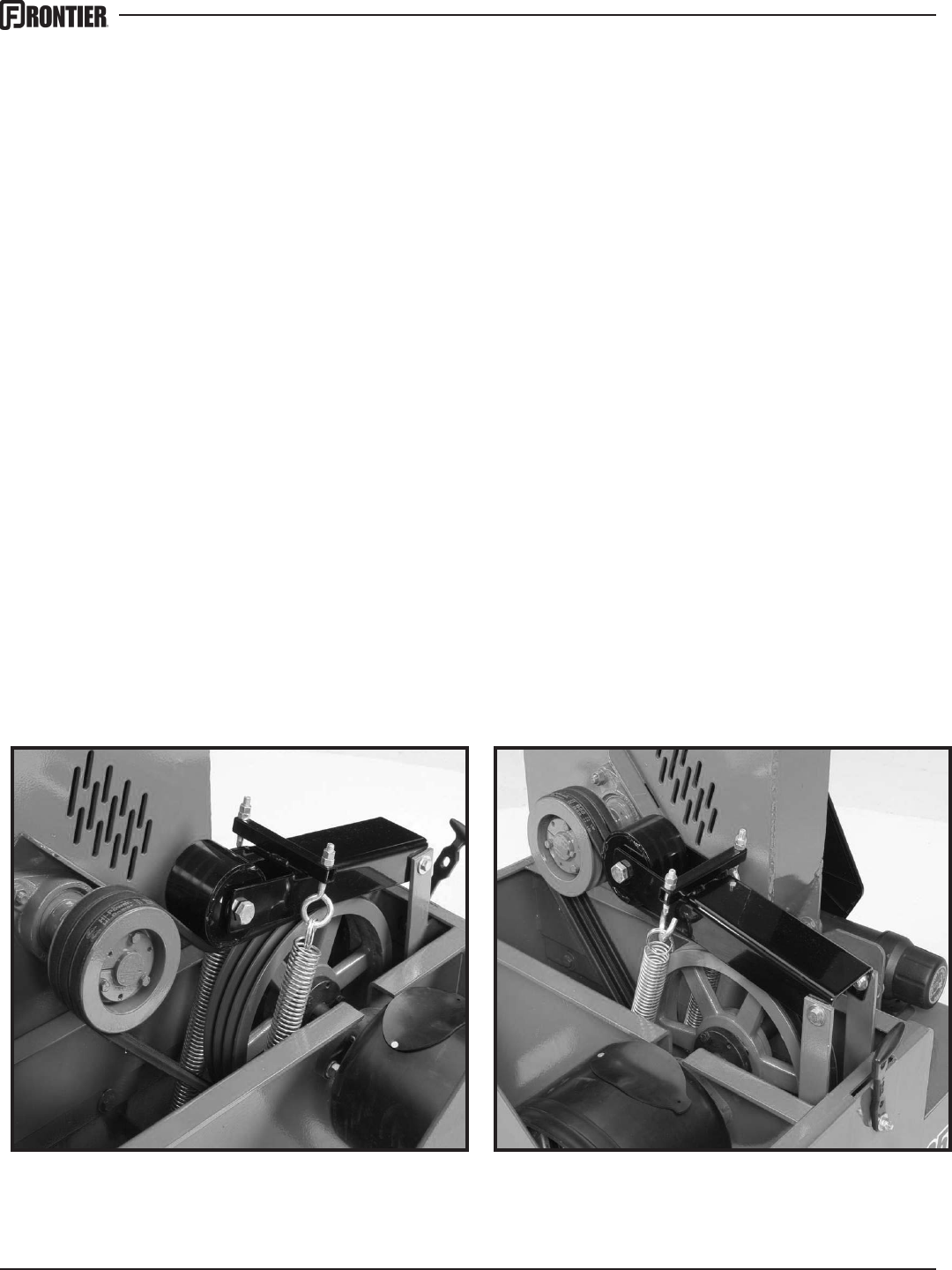

Belt tension

The belt tension is relatively maintenance free. The spring loaded idler will keep constant pres-

sure on the belts during use. However, there is a slight adjustment by tightening or loosening

the eye bolts, increasing or decreasing the spring tension.

Replacing the belts

Follow these steps to replace the drive belts. The WC1105 chipper uses (3) BX-58 belts.

• Remove the idler springs to release the tension on the belts.

• Remove the bolts that attach the front bearing and loosen the set screws in this bearing.

• Slide the bearing out far enough to lift the shaft out of the access slot. You may need to

remove the PTO shaft.

• Replace the belts and bolt the bearing back into position. Tighten the set screws in the

bearing and reinstall the idler springs. Be sure to put the safety shield back on.

Figure 6

Shield has been removed to show detail. All shields must be on at all times during operation!!

Figure 5