Engine

Maintenance

4 Clean Cooling System Grass

or chaff may clog cooling sys-

tem after prolonged service.

Continued operation with a

clogged cooling system causes

severe overheating and possi-

ble engine damage. Remove

blower housing and clean

regularly.

~

Ir:===;

~

9,

({J

'==""'/

,-J ,

-~4d~[=.ifL.

5 Spark Plug Clean and reset gap

at .030" every 100 hours of

operation.

Refer to chart on page 19 for

replacement spark plugs.

Caution: Blast cleaning of

spark plugs in machines that

use abrasive grit is not recom-

mended. Spark plugs should

be cleaned by scraping or wire

brushing and washing with a

commercial solvent or gaso-

line.

Refer to chart on page 19 for

replacement spark plugs.

6 Remove Carbon Deposits

Clean combustion chamber.

top of piston and around both

valves every 100-300 hours of

operation.

The use of unleaded gasoline is

recommended because of less build-up

of deposits in the combustion

chamber.

Adjustments

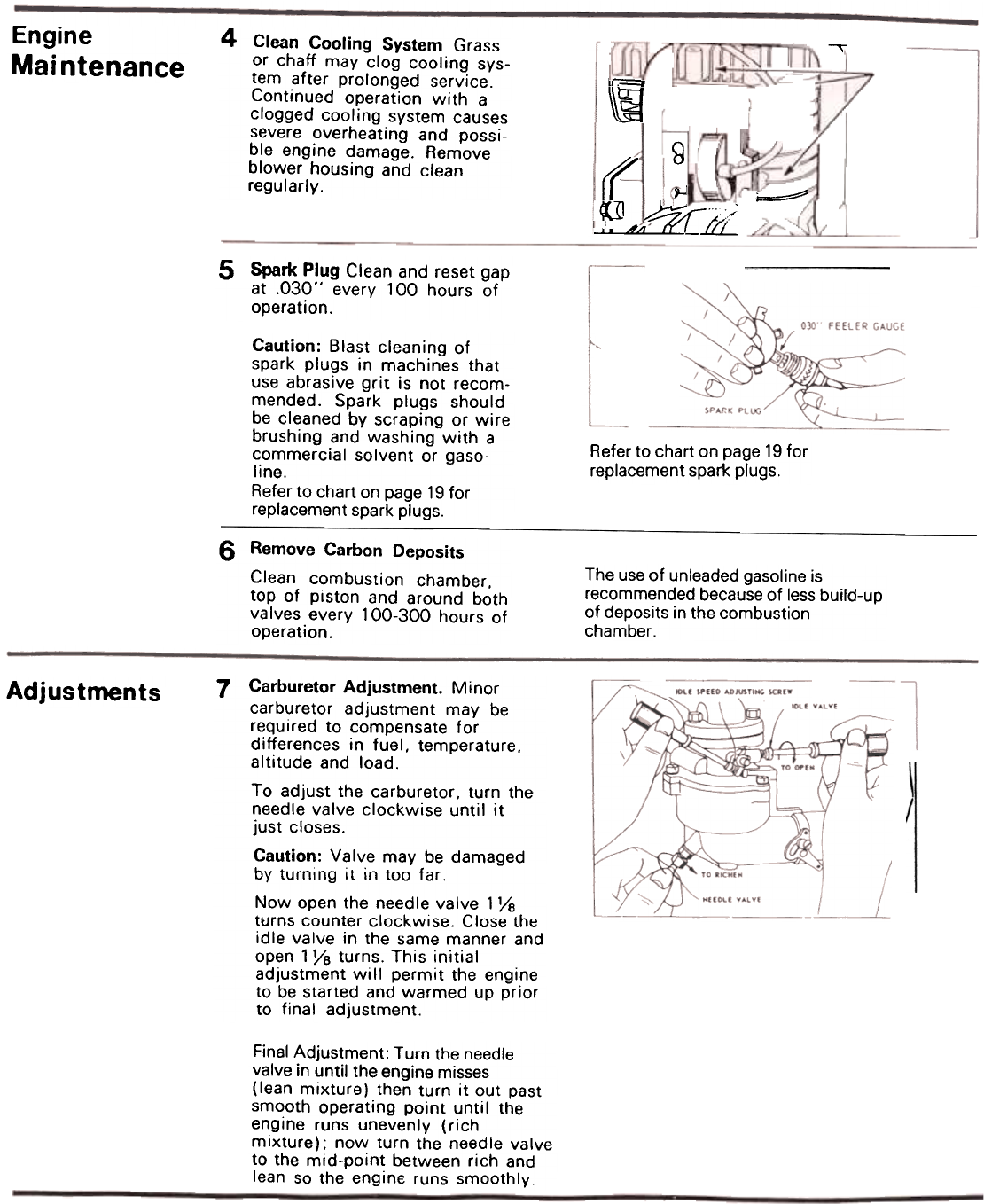

7 Carburetor Adjustment. Minor

carburetor adjustment may be

required to compensate for

differences in fuel, temperature,

altitude and load.

To adjust the carburetor. turn the

needle valve clockwise until it

just closes.

Caution: Valve may be damaged

by turning it in too far.

Now open the needle valve 1 Ys

turns counter clockwise. Close the

idle valve in the same manner and

open 1 Ys turns. This initial

adjustment will permit the engine

to be started and warmed up prior

to final adjustment.

Final Adjustment: Turn the needle

valve in until the engine misses

(lean mixture) then turn it out past

smooth operating point until the

engine runs unevenly (rich

mixture); now turn the needle valve

to the mid-point between rich and

lean so the engine runs smoothly