8 MHD56109 - Edition 9

LUBRICATION

General

Thread lubricant or an anti-seize compound use is recommended

for threaded shafts, capscrews and nuts. Unless otherwise stated,

remove old lubricant, clean part with an acid free solvent and

apply a new coating of lubricant to part before assembly.

Gear

Remove prevailing torque type nut (60) on side of hoist opposite

hand lever and remove gear case assembly (1). Remove old

grease and replace with new. For temperatures -29° to 10° C use

EP 1 grease or equivalent. For temperatures -1° to 49° C use EP 2

grease or equivalent.

Load Chain

WARNING

• Failure to maintain clean and well lubricated load chain may

result in chain failure causing injury, death or substantial

property damage.

1. Lubricate each link of chain weekly. Apply new lubricant

over existing layer.

2. In severe applications or corrosive environments, lubricate

more frequently than normal.

3. Lubricate hook and hook latch pivot points with same

lubricant used on load chain.

4. To remove rust or abrasive dust buildup, clean chain with an

acid free solvent. After cleaning, lubricate chain.

5. Use Ingersoll Rand LUBRI-LINK-GREEN® or a SAE 50

to 90W EP oil.

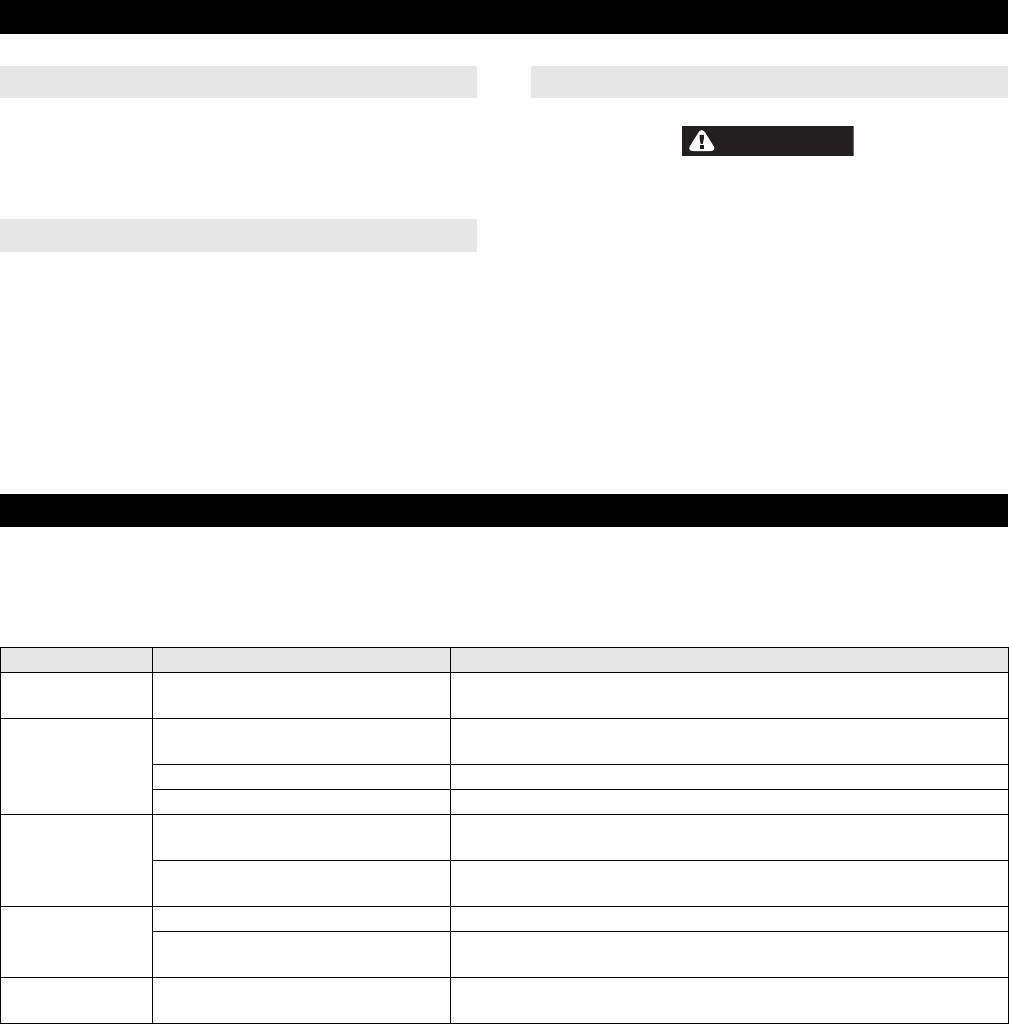

TROUBLESHOOTING

This section provides basic troubleshooting information. Specific causes to problems are best identified by thorough inspections performed

by personnel instructed in safety, operation and maintenance of this equipment. The chart below provides a brief guide to common hoist

symptoms, probable causes and remedies.

.

SYMPTOM CAUSE REMEDY

Hoist will not hold

rated load.

Brake may be slipping. Inspect and adjust or repair as described in “INSPECTION” and “MAINTE-

NANCE” sections.

Hoist will not lift

load.

Excess slack in load chain. Pull down on load chain while ratcheting until slack is removed and hoist

begins lifting load. Refer to “OPERATION” section.

Hoist is overloaded. Reduce load to within rated capacity.

Hoist is in NEUTRAL (N) mode. Ensure selector lever is in UP position. Refer to “OPERATION” section.

Load chain binds. Damaged load chain, pinion shaft, gears

or sheaves.

Disassemble and inspect components as described in “MAINTENANCE”

and “INSPECTION sections.

Load chain not installed properly

(twisted, kinked or “capsized”).

Inspect and adjust or repair as described in “INSPECTION” and “MAINTE-

NANCE” sections.

Load hook latch

does not work.

Latch broken. Replace hook latch.

Load hook bent or twisted. Inspect load hook as described in “INSPECTION” section. Replace if

necessary.

Hoist will not free

chain.

Brake is set. Rotate free chain knob counterclockwise. Refer to “OPERATION” section.