MHD56109 - Edition 9 11

Brake End Assembly

Follow steps 1 through 6 described in ‘Load Sheave Assembly’

and steps 1 through 5 described in ‘Gear End Assembly’.

CAUTION

• The brake will not operate properly if there is oil or grease

on brake friction disk (17).

1. Thread disk hub (15) onto drive shaft (3) until snug. Stepped

side of brake hub must face out.

2. Install pawl springs (13) and pawls (14) to posts on side

plate assembly B (brake end) (12) and secure with snap rings

(63).

3. Install first friction disk (17) followed by ratchet disk (18)

and second friction disk (17). Ratchet disk teeth must engage

two pawls (14) mounted on side plate assembly B (12). Only

clockwise rotation of ratchet disk (18) must be possible.

4. Install brake lever cover assembly (19) on side plate

assembly B (12). Brake cover assembly will locate on

threaded spacers (94). Secure with prevailing torque type

nuts (60).

5. Install spring (16) on drive shaft (3) then secure load sheave

(7) to prevent rotation and thread disk hub (15) onto drive

shaft (3) until snug.

6. Install change over spring (24), spring shaft (23) and change

over pawl (22) in lever handle assembly (25).

7. Install lever assembly on brake lever cover assembly (19).

Secure with washers (65) and screw (64).

8. Install screws (64) and washers (65).

9. To assist further assembly move selector lever to UP

position. Install hand wheel (28) and install screws (69) and

washer (68).

10. Install bushing (31).

11. Install and castle nut (70) until snug and then back nut off

3/4 turn and align slot with pin hole in drive shaft (3). Install

split pin (71) but do not bend ends apart. Test to ensure

adjustment block will freely move to free chain position. If

not, back off nut one more slot and retest. Install and bend

cotter pin ends apart.

12. Install cover (29) and secure in position with retainer wire

(30).

NOTICE

• Ensure hoist will properly shift from UP, DOWN and

NEUTRAL positions using selector lever. With selector lever

in NEUTRAL (center) position, turn free chain knob

counterclockwise. Ensure brake disengages and load chain can

be pulled in both directions without sticking or binding.

Bottom Hook Assembly

1. On 6 ton double fall hoists grease and install rollers (97) in

bore of idler sheave (56).

2. Install idler sheave shaft (96) through idler sheave (56) bore.

Ensure rollers (97) remain in position.

3. Secure idler sheave shaft (96) with retainer rings (95) at both

ends.

4. Install hook (51) in hook block (57).

5. Install idler sheave shaft (96) and secure with retainer ring

(95).

6. On single fall hoists install last link of load chain in hook

assembly and install capscrew (52) and nut (77).

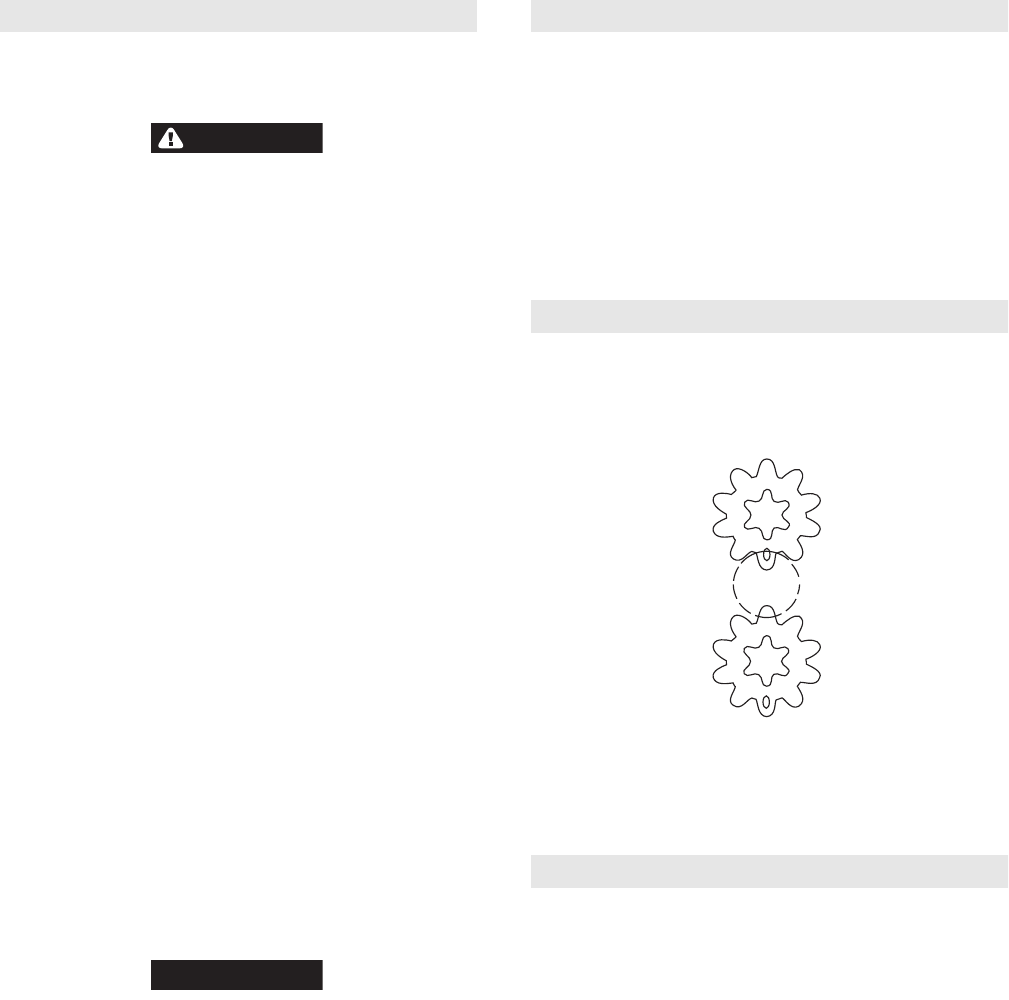

Gear Timing

For proper operation, timing marks on driver shaft gears (2) must

be in correct positions. Timing marks are circular impressions

near center of driver shaft gears (2). Refer to Dwg. MHP0827 on

page 11.

(Dwg. MHP0827)

(3/4 ton shown) timing marks typical for 3/4 - 6 ton

Load Test

Prior to initial use, all new, extensively repaired or altered hoists

shall be load tested by or under the direction of a person trained in

the operation and maintenance of this hoist, and a written report

furnished confirming rating of hoist. Test hoist to 125% of rated

hoist capacity. Testing to more than 125% may be necessary to

comply with standards and regulations set forth in areas outside

of the USA.

3/4 ton