6 MHD56109 - Edition 9

INSPECTION

WARNING

• All new, altered or modified equipment should be inspected

and tested by personnel trained in safety, operation and

maintenance of this equipment to ensure safe operation at

rated specifications before placing equipment in service.

Frequent and periodic inspections should be performed on

equipment in regular service. Frequent inspections are visual

examinations performed by operators or service personnel and

include observations made during routine equipment operation.

Periodic inspections are thorough inspections conducted by

personnel trained in the safety, operation and maintenance of this

equipment. ASME B30.21 states inspection intervals depend

upon the nature of the critical components of the equipment and

severity of usage.

Careful inspection on a regular basis will reveal potentially

dangerous conditions while still in the early stages, allowing

corrective action to be taken before the condition becomes

dangerous.

Deficiencies revealed through inspection, or noted during

operation, must be reported to designated personnel trained in

safety, operation and maintenance of this equipment. A

determination as to whether a condition constitutes a safety

hazard must be decided, and the correction of noted safety

hazards accomplished and documented before placing equipment

in service.

Records and Reports

Inspection records, listing all points requiring periodic inspection

should be maintained for all load bearing equipment. Written

reports, based on severity of service, should be made on the

condition of critical parts as a method of documenting periodic

inspections. These reports should be dated, signed by the person

who performed the inspection, and kept on file where they are

readily available for review.

Load Chain Reports

Records should be maintained documenting the condition of load

chain removed from service as part of a long-range load chain

inspection program. Accurate records will establish a relationship

between visual observations noted during frequent inspections

and the actual condition of the load chain as determined by

periodic inspection methods.

Frequent Inspection

The lever chain hoist should be inspected at the beginning of each

shift. Visual inspections should also be conducted during regular

service for any damage or evidence of malfunction which appears

between regular inspections.

1. OPERATION. Check for visual signs or abnormal noises

which could indicate a potential problem. Check chain feed

through hoist and on 6 ton units the hook idler sheave. If

chain binds, jumps or is excessively noisy or “clicks,” clean

and lubricate the chain. If problem persists, chain may have

to be replaced. Do not operate hoist until all problems have

been determined and corrected.

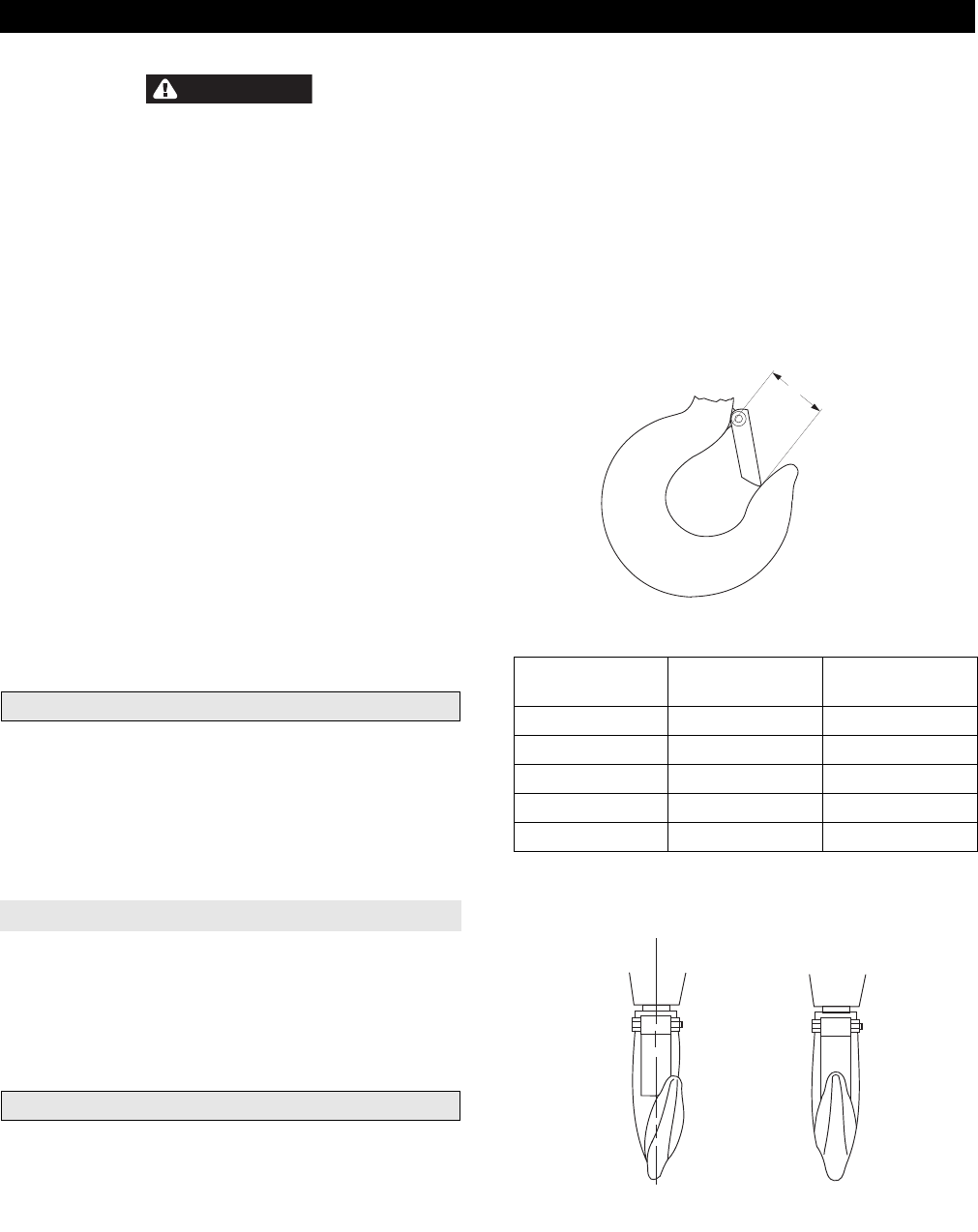

2. HOOKS. Check for wear or damage, increased throat width,

bent shank or twisting of hook. Replace hooks that exceed

the throat opening discard width (15%) shown in Table 1

(refer to Dwg. MHP0040 on page 6) or are twisted (refer to

Dwg. MHP0111 on page 6). If hook latch snaps past tip of

hook, hook is sprung and must be replaced. Check hooks

swivel easily and smoothly. Repair or lubricate as necessary.

(Dwg. MHP0040)

3. HOOK LATCHES. Check operation of hook latches.

Replace if broken or missing.

(Dwg. MHP0111)

Table 1

Model No.

Throat Width

(mm)

Discard Width

(mm)

SLB150 29 31

SLB200 32 35

SLB300 35 39

SLB600 44 48.3

SLB1200 50 55

Throat Width

Twisted

DO NOT USE

Normal

Can Be Used