12-12 108604 10/08

Before attempting any failure diagnosis of the electrical system, use a test light or voltmeter to check the

battery voltage. If the battery voltage is satisfactory, check the cleanliness and tightness of the terminals

and ground connections. A general understanding of electrical servicing and use of basic test equipment

is necessary for troubleshooting and repair.

Major overhaul or repair of the starting motor or charging system should be performed by trained

technicians only.

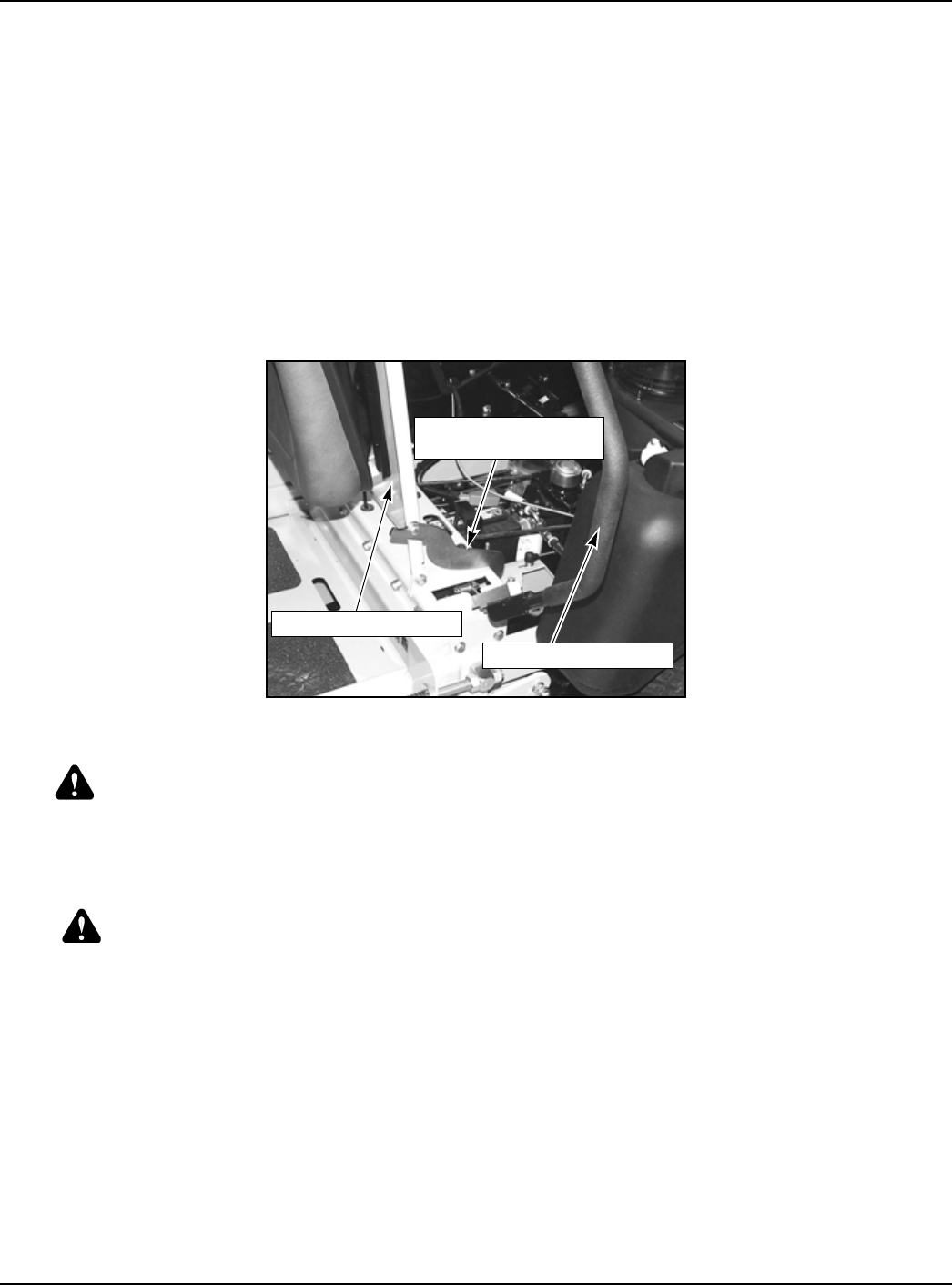

ACCESS TO ENGINE AND HYDRAULIC PUMPS

The hydraulic pumps are accessed by lifting the seat platform. The seat platform is hinged at the front. To

raise it, release seat latch and tilt seat platform up and forward.The seat platform catch ("FIG. 5") will

prevent the seat from going all the way over. However, if more access is desired under the seat platform,

the seat platform catch can be raised allowing the seat to pivot more. Make certain to place the control

arms in the park brake position and pivot the arm rests upward before placing the seat platform in

the full forward position to prevent arm rest damage.

WARNING: Always wear adequate eye protection when servicing the hydraulic system and battery.

HYDRAULIC SYSTEM

IMPORTANT: Never use hydraulic or automatic transmission fluid in this system; use only motor oil as

specified. Remember, dirt is the primary enemy of any hydraulic system.

WARNING: Hydraulic oil escaping under pressure can penetrate skin. Hydraulic oil may cause infec-

tion in a minor cut or opening in the skin. If exposed to hydraulic fluid, see a doctor at once.

Before applying pressure to hydraulic system, make sure all connections are tight and all hoses and lines

are in good condition. To find a leak under pressure, use a piece of cardboard or wood — never use your

hands. Relieve all pressure in the system before disconnecting or working on hydraulic lines. To relieve

pressure, lower all attachments and shut off engine.

The 1.0 U.S. gallon (3.79 liter) hydraulic reservoir is located in front of the engine and under the operator’s

platform "FIG. 6".

Check oil level in hydraulic system after every 50 hours of operation or weekly, whichever occurs first.

Check more often if system appears to be leaking or otherwise malfunctioning.

Fluid level should be 1” from top of reservoir. Use only SAE 10W40 SG, SF/CC, CD service motor oil.

Change hydraulic system filter element ("FIG. 6") after first 50 hours of tractor operation, then replace filter

and oil in reservoir every 500 hours thereafter. When changing hydraulic oil use 1/2 unit (approximately

3.5 oz.) of Lubrizol additive (Hustler P/N 027912). This additive, available from your Hustler dealer, will

increase the performance life of the hydraulic system components.

FIG. 5

SEAT PLATFORM

CHECK

SEAT PLATFORM

CONTROL LEVER