2. Service elements only when restriction indicator shows

red. Check restriction indicator daily or more

frequently if operating in dusty conditions.

3. Loosen wing nut and remove element. Clean the

canister with a damp cloth.

4. Before installing a new element, inspect it by placing a

bright light inside and rotate the element slowly,

looking for any holes or tears in the paper. Also check

gaskets for cuts or tears. Do not attempt to use a

damaged element which will allow abrasive particles

to enter the engine.

5. Reinstall the dust cup. Make sure it seals all the way

around the air cleaner body, then tighten the clamping

thumb screw.

6. Check all fittings and clamps periodically for tightness

and inspect hoses for holes or cracks.

7. Periodically check the intake hose for signs of ingested

dust. Locate and repair the source of ingested dirt.

8. Never operate a machine without an air filter installed.

When operating in extremely dirty conditions, Hustler

recommends Pre-Cleaner Kit, part number 462135, be used

to extend the life of the element. The Pre-Cleaner mounts

on top of the air filter canister and is designed to remove dirt

and debris before it enters the air filter.

Cooling system

Engine cooling is accomplished with circulated water and

Ethylene Glycol mixture. The radiator is equipped with a

pressure cap and recovery tank. System capacity for the

4300 and 4500 tractors is approximately 3.25 U.S. gallon

(12.3 liter). System capacity for the 4200 tractor is

approximately 2.50 U.S. gallon (9.5 liter). System capacity

for the 4400/4420/4600 tractors is approximately 2.75 U.S.

gallon (10.4 liter). A 50-50 mixture is recommended for all

season operation. This mixture provides freeze protection to

-32 degrees F (-35 degrees C). Should temperatures fall

below this level, additional Ethylene Glycol must be added

to the mixture.

Visually inspect the system daily prior to operating

tractor. Check coolant level in the recovery tank located

under the engine hood on the right side, behind fender (Fig.

5-17). The tank is marked with cold engine and hot engine

levels. Level should not go above the hot level mark when

engine is at normal operating temperature, and coolant

should be added to maintain level at or slightly above the

cold level mark at all times. When adding coolant, pre-mix

the solution before adding it to the recovery tank. It is not

necessary to remove radiator cap for adding small amounts

of coolant to system.

DANGER: Never remove radiator cap when

engine is hot. Pressurized hot steam and water

may be released, causing serious burns or

possible blindness.

The system should be drained, flushed and refilled with

fresh solution after every 500 hours of operation. The lower

radiator tank is equipped with a drain cock. Remove the

radiator cap and open this drain for emptying system.

If frequent refilling is necessary or if coolant appears

rusty, thoroughly check the system. Refer to the engine

manual for information on checking and cleaning system.

The engine cooling fan draws air through both the

hydraulic oil cooling and engine cooling radiators. These

are protected by a screen shroud. Keep the shroud clean at

all times and make sure trash is not allowed to accumulate

on or between the radiators, nor allow the fins and cores to

become plugged.

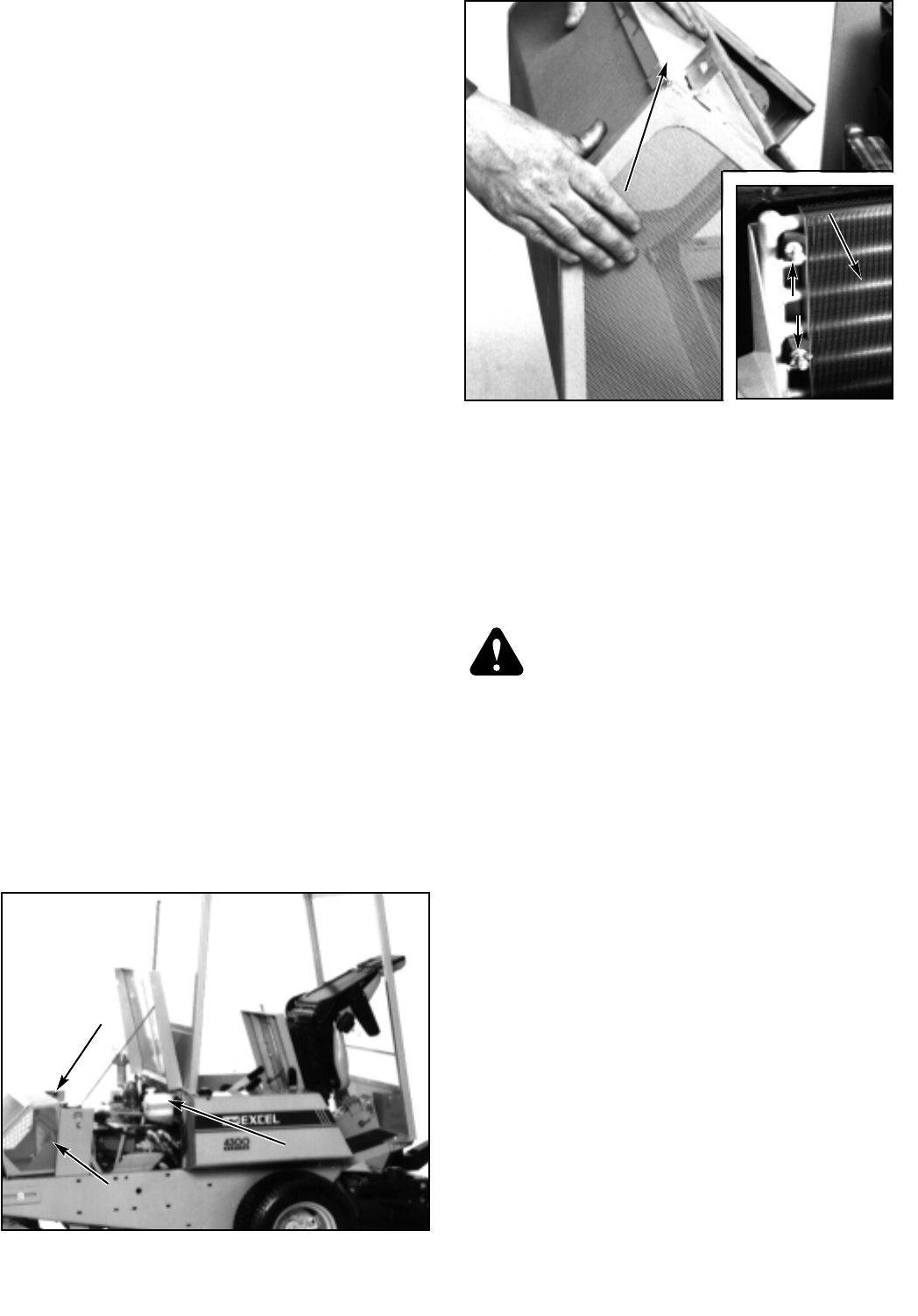

The rear screen is removed by lifting engine hood and

inserting the support rod. Loosen the strap clamps, one on

each side at top, tilt the shroud back, then move the bottom

forward to clear the retaining clips and lift shroud off.

The oil cooler may be separated from its mounting by

loosening the four rubber mounting pad wing nuts and

sliding the cooler assembly back and off the mounts. It

should be noticed that it is not necessary to remove the hex

lock nut, wing nut or rubber spacer to remove or replace the

cooler assembly for servicing or cleaning (Fig. 5-18).

Never force anything into the radiator fins which may

bend or distort them. For cleaning, use compressed air or

pressurized water only.

728444 Rev. 11/02

5-15

Figure 5-17

CCoooollaanntt

RReeccoovveerryy

TTaannkk

Screen Strap

Radiator

Screen

Figure 5-18

WWiinngg NNuuttss

OOiill CCoooolleerr

Radiator Screen Shroud