728444 Rev. 11/02

5-1

•–Refer to break-in services for initial change.

+ – More often under dusty or dirty conditions and during hot weather.

X – Torque after first 50 hours also.

Y – Torque after first 2 hours of operation.

XX – Check monthly or every 200 hours, whichever comes first.

Z – Perform initial hydraulic filter change after 50 hours, at same time initial engine

break-in adjustments are performed.

A – See Engine Manual. Refer to Engine Owner’s Manual for recommendations and

other maintenance items.

B – 4200/4400/4420/4600 change after first 35 hours of operation. Refer to Engine

Owner’s Manual for recommendations and other maintenance items.

C – 4200/4400/4420/4600 tractors only.

D – 4300/4500 tractors only

E – Use oil with a rating equivalent to CD or higher

F – Inspect every 100 hours and replace if worn or cracking is noticed. Otherwise,

replace every 1000 hours or 2 years whichever comes first.

G – Do not clean filter element. Replace with a new one.

H – Check hydraulic and fuel line hoses for any cracks or leaks.

I – Trash & clipping buildup around engine could cause a fire. Keep engine

compartment and muffler area clean.

NOTE: After completing maintenance cycle (1000

hours), repeat cycle.

Introduction

WARNING: Unless specifically required, DO

NOT have engine running when servicing or

making adjustments to tractor. Engage neutral

lock levers and parking brake. To prevent

carbon monoxide poisoning, be sure proper

ventilation is available when engine must be

operated in an enclosed area. Read and observe

safety warnings in front of manual.

Regular maintenance is the best prevention for costly

downtime or expensive, premature repair. The following

pages contain suggested maintenance information and

schedules which the operator should follow on a routine

basis.

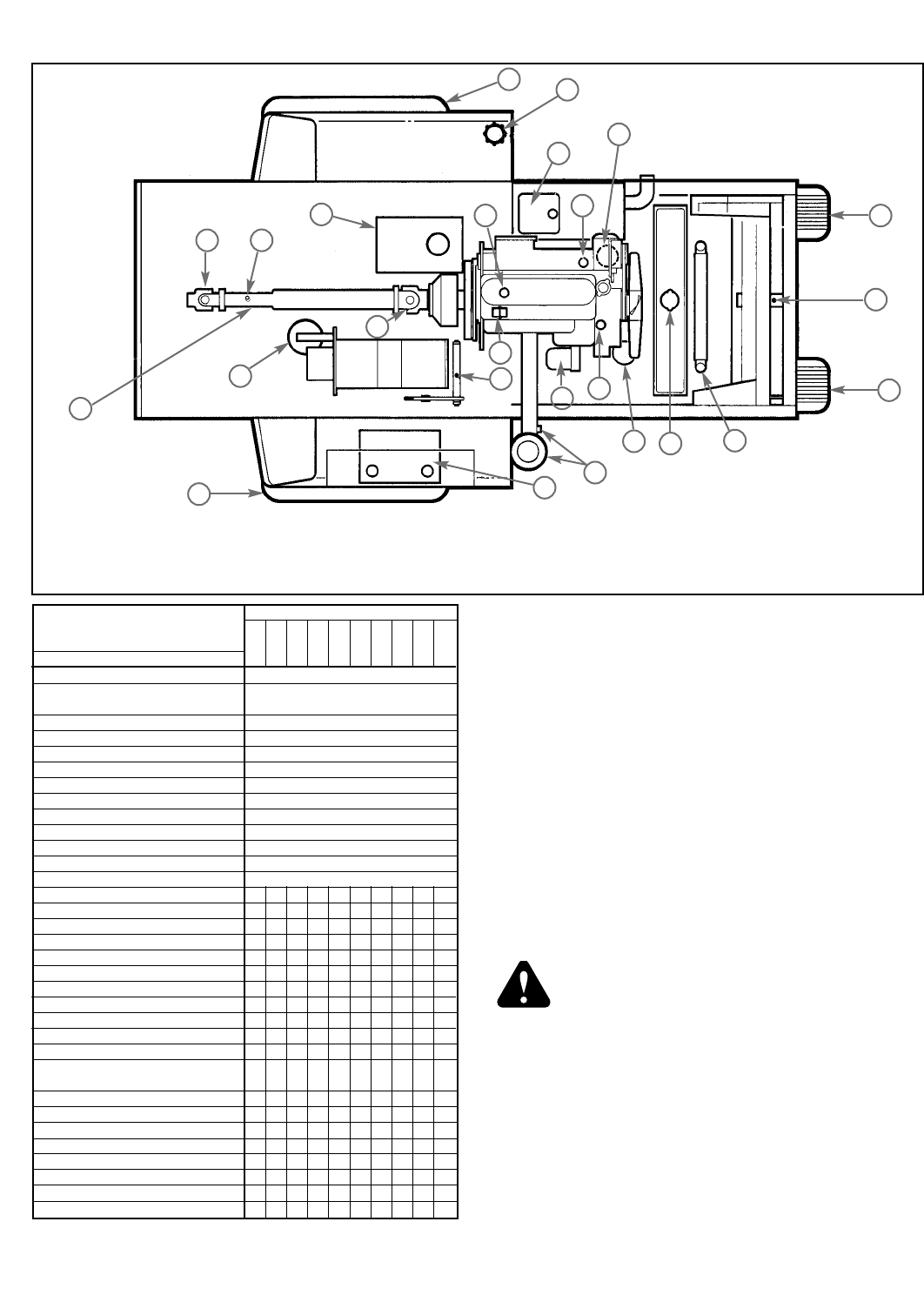

MAINTENANCE AND ADJUSTMENTS

AC

F

ABE

D

H

D

AD

AD

A

AD

1

2

3

4

2

21

14

8

7

19

9

10

15

17

18

20

22

20

11

12

16

6

19

5

Maintenance Locator Chart

1. PTO Shaft 17. Radiator Cap

2. U-Joint Grease Zerks (2) 7. Battery Location 12. Oil Dipstick (diesel units) 18. Oil Cooler

3. PTO Spline Grease Zerk 8. Air Filter & Service Indicator 13. Oil Fill Location 19. Drive Tire

4. Hydraulic System Filter 9. Oil Filter (gas units) 14. Fuel Filter (gas units) 20. Rear Tire

5. Hydraulic Reservoir 10. Oil Dipstick (gas units) 15. Fuel Filter (diesel units) 21. Pump Clutch Mount Grease Zerk

6. Fuel Gauge & Filler Cap 11. Oil Filter Location (diesel units) 16. Coolant Recovery Tank 22. Tail Wheel Pivot

INTERVALS (HOURS)

MAINTENANCE SCHEDULE

SERVICE AT INTERVALS INDICATED

Check coolant level Every 8 hours

Visually inspect tractor for loose hardware

and/or damaged parts Daily

Visually inspect tires Daily

Check oil level, engine Every 4 hrs.

Check radiator screen Every 4 hrs.

Clean air filter intake screen Every 4 hrs.

Check fuel level Every 8 hrs.

Check air cleaner service indicator+ Every 8 hrs.

Lube rear wheel axle Every 8 hrs.

Visually inspect radiator core+ Every 40 hrs.

Lube rear wheel bearings (2) Every 40 hrs.

Lube PTO spline Every 50 hrs.

Tighten hub bolts on wheels (Y)(X) Every 50 hrs.

Check oil level, hydraulic XXXXXXXXXX

Lube PTO U-joints (2) XXXXXXXXXX

Check alternator belt tension XXXXXXXXXX

Check pump belt tension & condition XXXXXXXXXX

Check steering lever tension XXXXXXXXXX

Change engine oil and filter +* XXXXXXXXXX

Lube pump clutch mount XXXXXXXXXX

Check governor oil level XXXXXXXXXX

Check fuel & hydraulic hoses XXXXXXXXXX

Check alternator & governor belt tension XXXXX

Lubricate throttle, governor & choke linkage XXXXX

Check grommets and ball joints

on steering linkage (XX) XXXXX

Adjust idle mixture & speed X X

Change fuel filter + X X

Replace spark plugs X X

Clean hydraulic filler cap X X

Clean radiator core + X X

Change hydraulic filter (Z) and oil + X

Change radiator coolant X X

Check steering shock absorbers X X

1000

900

800

700

600

500

400

300

200

100

13

G

I