3. Damaged filter, seals or canister.

4. Incorrect air filter element size.

5. Use of poorly designed aftermarket air filter elements.

Air cleaner servicing is an inexpensive maintenance check

that can prevent costly non-warrantable premature engine

damage.

Overservicing

Overservicing occurs when an air filter element is

removed for cleaning or replacement before it is necessary.

Each time the filter is removed a small amount of dirt and

dust could fall in the intake system. This accumulated dirt

can cause a dusted engine. It only takes a few grams of

ingested dirt over the normal service life of an engine to

cause a dusted engine.

An air cleaner element should only be changed when the

restriction indicator shows red. Do not clean element,

replace with a new element only. Cleaning used air filter

elements, through improper cleaning procedures, can get

dust on the inside of the filter causing dirt ingestion and

engine failure.

It is important to note that whenever an air filter element

is cleaned by any method, the person or company

performing the cleaning assumes responsibility for the

integrity of the filter from then on. The Donaldson

warranty for air filters expires upon cleaning or

servicing in any manner because the condition of the

filter after servicing is completely out of their control.

Therefore, on a dust ingested engine failure, there will be

no warranty consideration if the air filter element has

been cleaned or serviced in any manner.

A partially dirty air filter element works better than a new

element. Therefore, a dirty filter element is not bad for the

engine unless it is excessively restricting the air flow and

engine performance is affected. The reason is simple. The

media in the filter must be porous to allow air to pass

through it. When dirty air passes through the filter, the dirt

plugs some of the holes in the media and actually acts as

part of the filter media. When the next round of dirt enters,

the first dirt helps filter out even smaller particles making

the filter more efficient at stopping dirt from entering the

engine. This is referred to as barrier filtration.

Of course, at some point the filter media becomes too

clogged to allow air to pass. That is why it is so important

to monitor airflow restriction with a restriction indicator. A

restriction indicator takes the guesswork out of air cleaner

servicing and allows you to safely benefit from the filter’s

optimum performance.

The mowing conditions will determine the frequency of

air filter element changing. Generally, it’s time to service

the air filter element when the restriction indicator shows red

or when the engine begins to lose power.

Improper installation of an air filter element

Dust must not leak past the seals on each end of the air

filter element. The filter must be aligned within the canister

and properly seated for an effective seal so that no dirt can

enter the engine. Be sure to tighten the filter retaining nut

securely to insure a proper seal.

Damaged filter, seals or canister

Never bang or bump the filter element against the tire or

any solid object, as dust and dirt particles will be forced

through the media causing continual passing of dirt into the

engine. Visually inspect the outside of the air cleaner

canister periodically for external damage and replace if

necessary.

Incorrect air cleaner element

Use only the correct Donaldson air filter element, Hustler

part number 032029, which is designed to fit the canister

properly.

Hustler air filter elements have the correct media

composition, filter area, micron size and dimensions.

Always use genuine Hustler filters. Many aftermarket filters

have been found to be incompatible with Hustler’s canisters

and engines.

The air filter must remain intact to block passage of dirt

and foreign particles from entering the engine. Being

inclined to disbelieve the need for more expensive air filter

elements used on gasoline and diesel engines may cause

some individuals to opt for a less expensive part.

The filter element must be sufficient size and construction

to withstand stresses, caused by rapid cycling of the air

volume demanded by the engine, without cracking or tearing

under fatigue and pressure (especially diesel engines).

Therefore, Hustler Turf Equipment and the engine

manufacturers have carefully selected a reliable filter

designed to fit the needs of the engines. The filter specified

is a Donaldson filter, Hustler part number 032029.

Owners should be reminded that failure to use original

equipment replacement parts is an “alteration” and will not

be considered for warranty in the event of engine damage.

Recommended service procedure

1. Check dust cap. Dust or water should not be allowed

to build up closer than one inch from the baffle. The

Vacuator™ Valve should eliminate dust and water

from cup automatically, empty only as necessary.

Check to see if the Vacuator™ Valve is functioning

and in good condition. Replace if necessary. Do not

operate machine without the Vacuator™ Valve

installed.

728444 Rev. 11/02

5-14

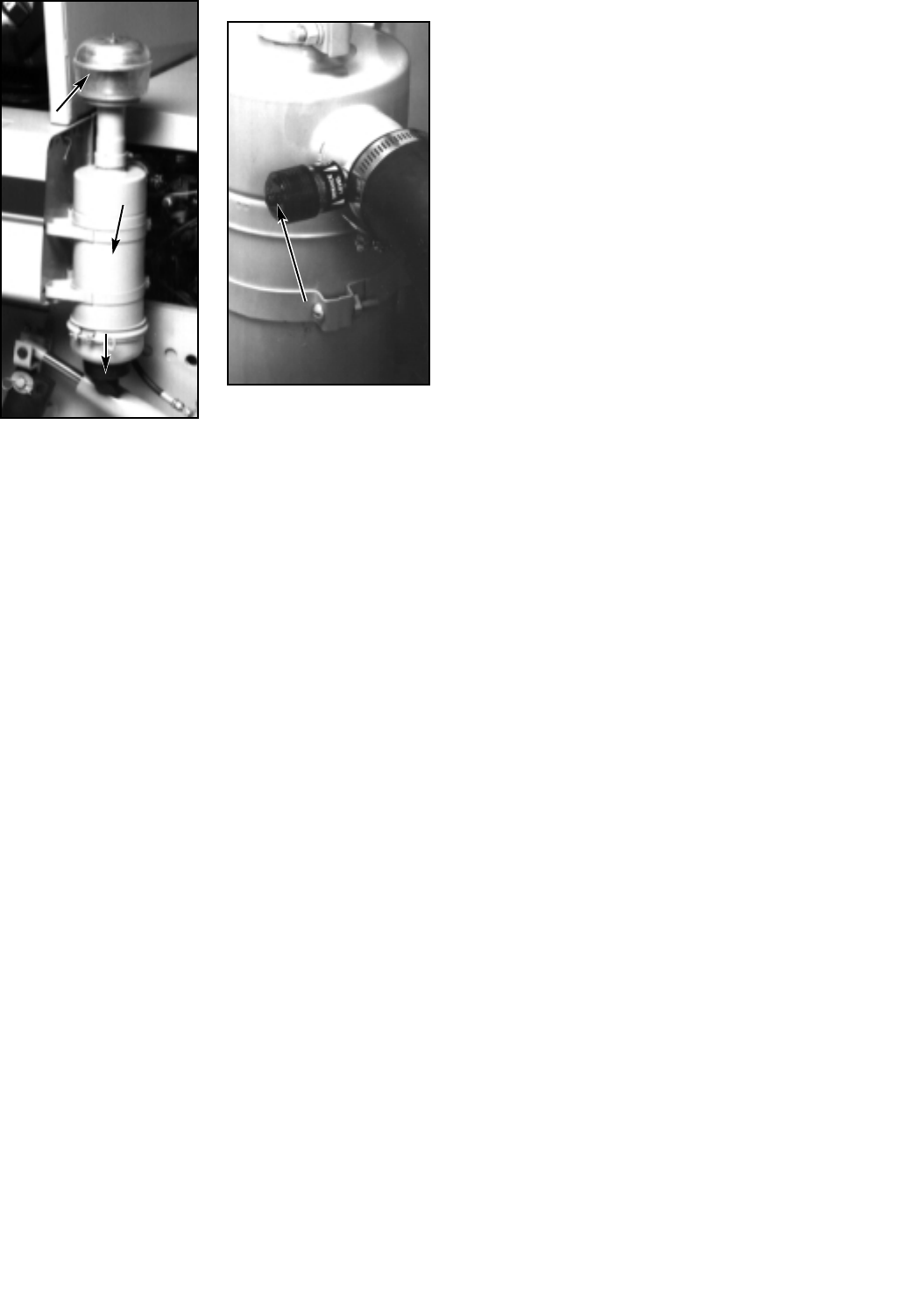

Figure 5-16

VVaaccttuuaattoorr

VVaallvvee

PPrree--CClleeaanneerr

CCaanniisstteerr

SSeerrvviiccee

IInnddiiccaattoorr