Remain alert for unusual noises, they could be signaling a

problem. Visually inspect the machine for any abnormal

wear or damage. A good time to detect potential problems

is while performing scheduled maintenance service.

Correcting the problem as quickly as possible is the best

insurance.

WARNING: Keep your machine clean, remove

any deposits of trash and clippings, which can

cause engine fires and hydraulic overheating as

well as excessive belt wear.

Clear away heavy build-up of grease, oil and dirt,

especially in the engine and hydraulic reservoir area; minute

dust particles are abrasive to close-tolerance engine and

hydraulic assemblies.

Some repairs require the assistance of a trained service

mechanic and should not be attempted by unskilled

personnel. Consult your Hustler service center when

assistance is needed.

Torque values

Particular attention must be given to tightening the drive

wheel lug and wheel motor nuts. Failure to correctly torque

these items may result in the loss of a wheel, which can

cause serious damage. Torque values given below are in foot

pounds.

Wheel (lug) nuts .............................65-75 ft.-lbs.

Wheel motor nut .........................425-450 ft.-lbs.

It is recommended that these be checked after the first 2

hours of operation, initially and every 50 hours following

removal for repair or replacement.

For engine torque values, see engine owner’s manual.

Tires

It is important for level mowing that the tires have the

same amount of air pressure. The recommended pressures

are:

Drive Wheels........................................14-18 psi

Tail Wheels...........................................14-18 psi

If the machine has Hustler Range Wings or a Hi-Lift

BAC-VAC then the tire pressure should be increased to:

Drive Wheels........................................20-22 psi

Tail Wheels ..........................................20-22 psi

Solid fill tires are not recommended for Hustler turf

equipment. On any machine, with a failure due to solid

filled tires, the warranty claim will be denied.

Hour meter

To recognize when your machine needs servicing, check

the hour meter and the maintenance schedule. The hour

meter shows the number of hours the engine has run and the

maintenance schedule lists the service intervals.

Lubrication

There are seven grease fittings on the tractor which

require regular servicing. Use a good grade SAE multi-

purpose grease and wipe accumulated dirt from fitting

before attaching grease gun. Refer to the diagram for

location and frequency.

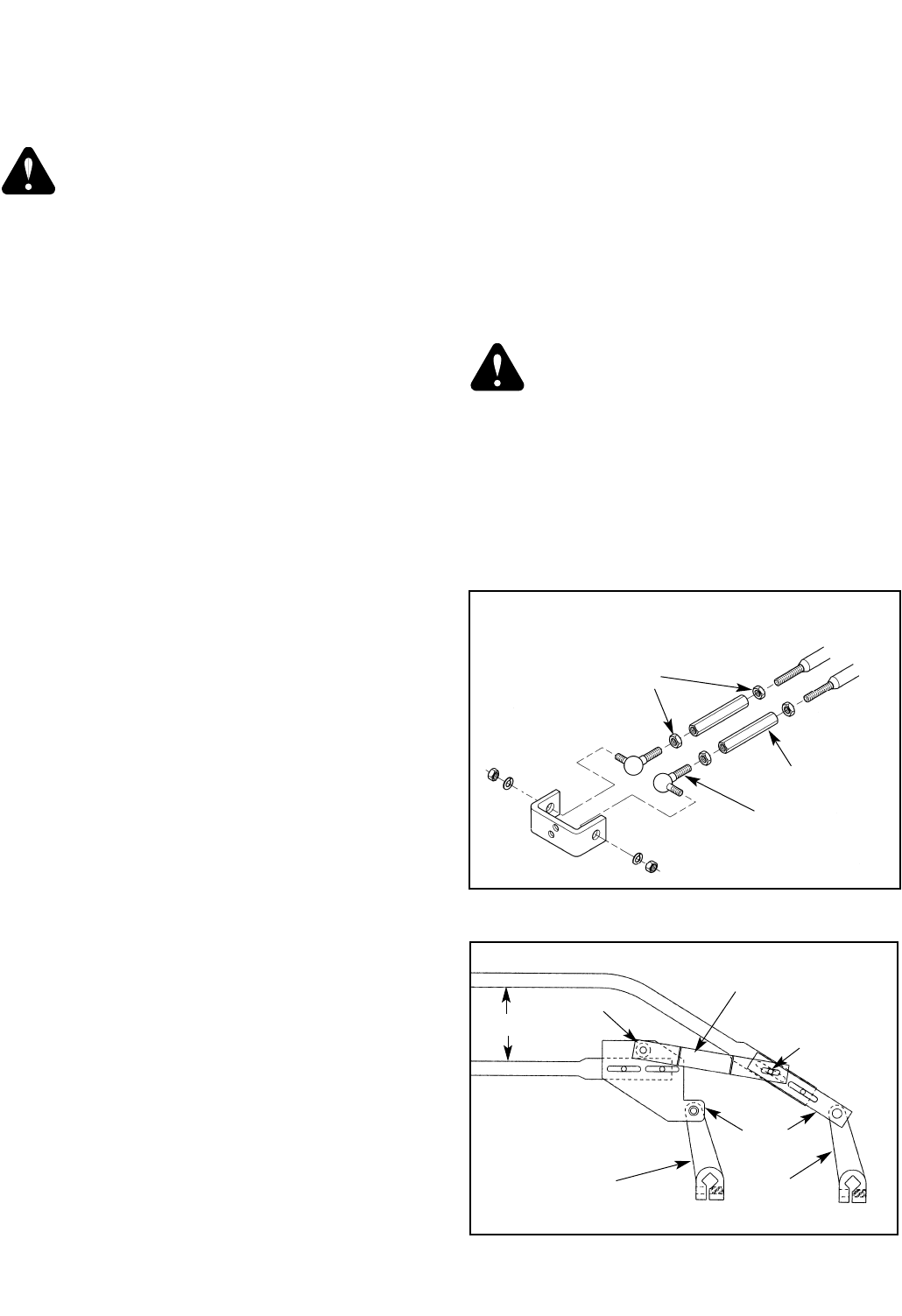

Steering linkage

There are two types of steering adjustments that are

discussed in this section.

1. Neutral adjustment in the neutral lock position.

2. The rotational resistance spring and linkage connecting

the two pump levers, located near the pump.

Prior to making either of these adjustments, visually

inspect the urethane grommets at the hydraulic pump end of

the steering control levers (or linkage straps) and ball joints

at front at least once a month or every 200 hours of

operation, whichever occurs first. These grommets and ball

joints must be replaced if lost or worn.

WARNING: Failure to maintain these

grommets and ball joints will affect steering.

Visually inspect steering shock absorbers every 500 hours

for damage or wearing. If excessive oil leakage is evident,

then replace that shock absorber.

The tractor steering has been factory adjusted to eliminate

creeping when the neutral lock is engaged. However, should

the tractor begin to creep, the steering control lever linkage

can be adjusted as follows (Fig. 5-1 and 5-2):

728444 Rev. 11/02

5-2

Figure 5-2

Loosen this bolt

before making

neutral

adjustments &

to bring spring

to vertical

position when in

neutral

Connecting

link

Front pump arm

Rear pump

mount

Neutralizer

spring

Linkage rod

Linkage

straps

Rear steering linkage adjustment

Figure 5-1

Lock nut

Turnbuckle

Ball joint

Front end of steering linkage