601396_0109 5-5

will tear rather than cut the grass, leaving a brown ragged top on

the grass within a few hours. A dull blade also requires more

power from the engine.

Replace any blade which is bent, cracked or broken.

WARNING: Never attempt to straighten a bent blade

by heating, or weld a cracked or broken blade as the

blade may break and cause serious injury. Replace

worn or damaged blades.

DANGER: Never work with blades while engine is

running or deck clutch switch is engaged (on).

Always place deck clutch switch in the disengaged

position, place steering control levers in the park brake

position and turn engine off and disconnect negative

battery cable. Block up mower when you must work

under it. Wear gloves when handling blades. Always

check for blade damage if mower strikes rock, branch or other

foreign object during mowing!

WARNING: Always wear adequate eye protection

when grinding mower blades.

Always place deck clutch switch in the disengaged position,

place steering control levers in the park brake position and turn

engine off and disconnect negative battery cable. Block up

mower when you must work under it. Wear gloves when

handling blades. Always check for blade damage if mower

strikes rock, branch or other foreign object during mowing!

Mower blade removal

Use a 15/16" wrench to remove the 5/8" cap screw holding the

blade to the spindle shaft from underneath. NOTE: A blade

holding tool (part number 381442) is available from Hustler

Turf Equipment. It is designed to prevent the blades from

rotating when they are being removed or installed on the

spindle. Contact your Hustler dealer for more information.

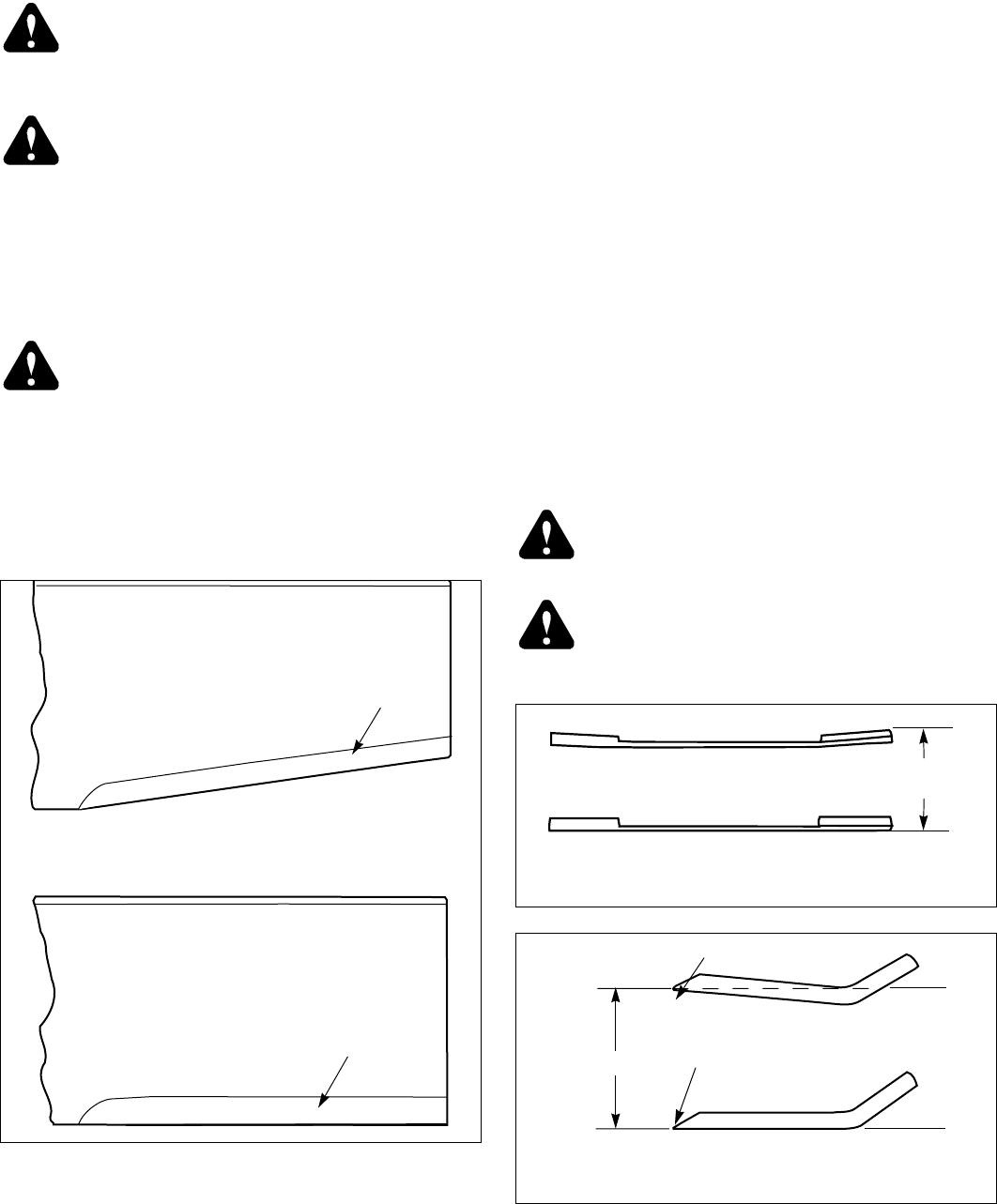

Sharpen the blades on a grinder following pattern as shown

(Fig. 5-5). Touch-up sharpening can be done with a file.

Check the blades for balance following grinding. A

commercial balancing tool is available through most hardware

supply stores, or balancing can be done by placing the blade on

an inverted line punch or 5/8" bolt. Blade should not lean or tilt.

Spin the blade slowly, blade should not wobble. If blade is out

of balance, true it up before reinstalling.

Lay the blade on a flat surface and check for distortion

(Fig. 5-6 and Fig. 5-7). Replace any distorted blade.

Do not re-use spindle bolts which have stripped, worn or

undercut threads. Torque bolts on spindles to 118 foot-pounds

(160.01nm) when reinstalling blades.

IMPORTANT: The blade sail (curved part) must be point-

ing upward toward the inside of the deck to ensure proper cut-

ting.

IMPORTANT: When mounting blades, rotate them after

installation to ensure blade tips do not touch each other or sides

of the mower.

WARNING: Failure to correctly torque the bolt may

result in the loss of the blade which can cause serious

injury.

WARNING: Mower blades are sharp and can cut.

Wrap the blade(s) or wear gloves and use extra caution

when servicing them.

Fig. 5-5

Resharpening

pattern

Do not sharpen to original pattern (below). It is

easier to get a straight cutting edge following

the resharpening pattern shown above.

Original edge

Fig. 5-6

Fig. 5-7

Warped Blade (Replace)

Straight Blade

Cutting

plane

Comparison of Warped and Straight Blades

Cutting edge

Twisted Blade Edge

(replace)

Cutting edgeCutting Plane

Straight Blade Edge

End view of blades, comparing

twisted and straightened blades