ASSEMBLY

7

Use terminal access doors for:

• Inspection for secure connections (to tighten hard-

ware).

• Inspection for corrosion.

• Testing battery.

• Jumping (if required).

• Periodic charging.

TERMINAL

ACCESS

DOOR

POSITIVE

(RED)

CABLE

NEGATIVE

(BLACK)

CABLE

HEX

BOLT

FLAT

WASHER

DISCARD TERMINAL

PROTECTIVE CAPS

LOCK

WASHER

HEX NUT

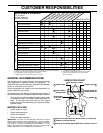

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment knob.

• Remove cardboard packing on seat pan.

• Place seat on seat pan and assemble shoulder bolt.

• Assemble adjustment knob and flat washer loosely.

Do not tighten.

• Tighten shoulder bolt securely.

• Lower seat into operating position and sit on seat.

• Slide seat until a comfortable position is reached which

allows you to press clutch/brake pedal all the way

down.

• Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment knob securely.

FIG. 2

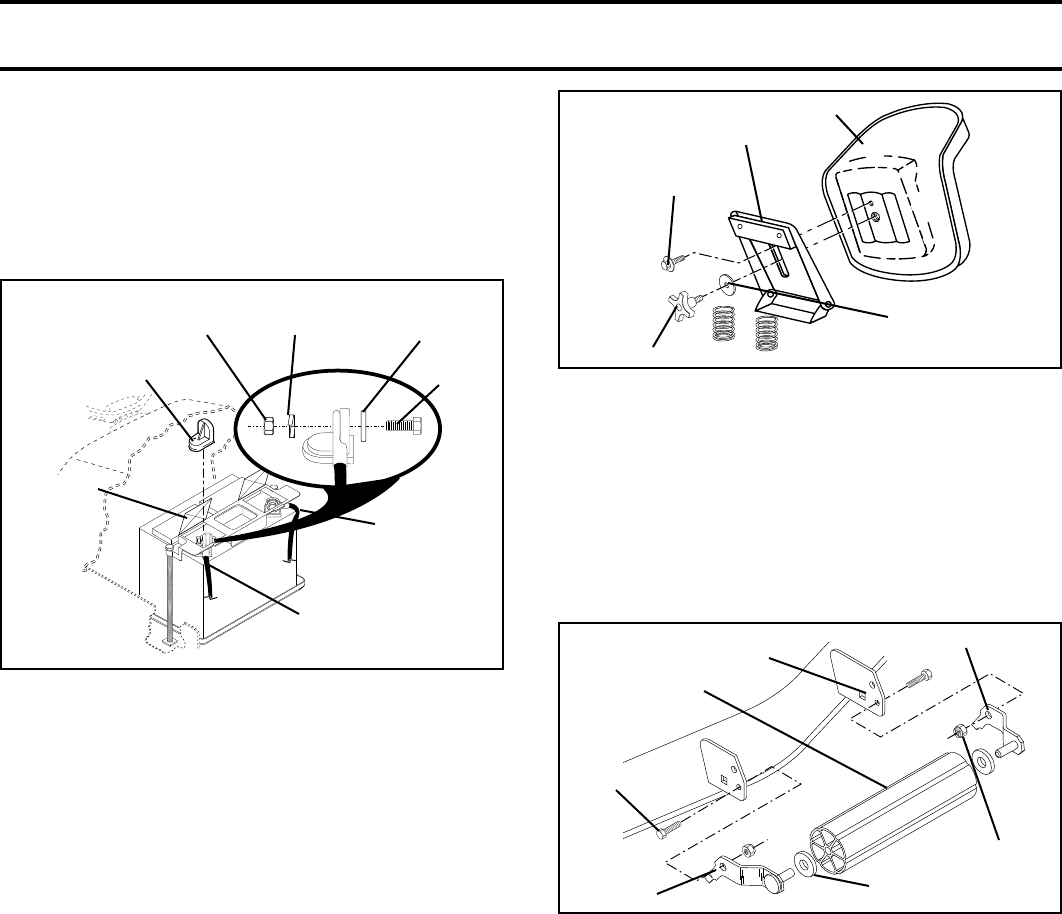

TO ATTACH NOSE ROLLER (See Fig. 4)

• Position brackets, washers and nose roller between

deck mounting brackets as shown. Be sure to position

brackets on correct side, as shown.

• Install hex bolts and locknuts as shown. Tighten

hardware securely.

NOTE: Be sure tabs brackets are positioned in tab holes

in deck brackets.

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory for

shipping purposes. Correct tire pressure is important for

best cutting performance.

• Reduce tire pressure to PSI shown in “PRODUCT

SPECIFICATIONS” on page 3 of this manual.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adjusted. See “TO ADJUST

BRAKE” in the Service and Adjustments section of this

manual.

FIG. 4

"B" BRACKET TAB

WASHER

LOCKNUT

TAB HOLE

NOSE ROLLER

"A"

BRACKET

TAB

HEX

BOLT

FLAT

WASHER

SEAT

SEAT PAN

SHOULDER

BOLT

ADJUSTMENT KNOB

FIG. 3