26

MAINTENANCE & LUBRICATION

SERVICE DAILY:

1. Check engine oil level.

2. Check blade guard for damage.

3. Check engine air lter, replace if dirty. Service sooner

if used in dusty conditions.

4. Clean machine daily.

SERVICE EVERY 50 HOURS:

1. Replace engine oil and lter.

2. Clean engine/motor air ns.

3. Lubricate Depth Control Grease Fitting (X).

4. Check wheels for wear or damage.

5. Check blade drive belt tension.

SCHEDULED MAINTENANCE QUICK REFERENCE:

Before performing any maintenance, ALWAYS park the machine on a level surface with the engine “OFF” and

the engine switch set in the “OFF” position. Let the machine cool down! Other maintenance and repairs

should only be carried out by a qualied technician.

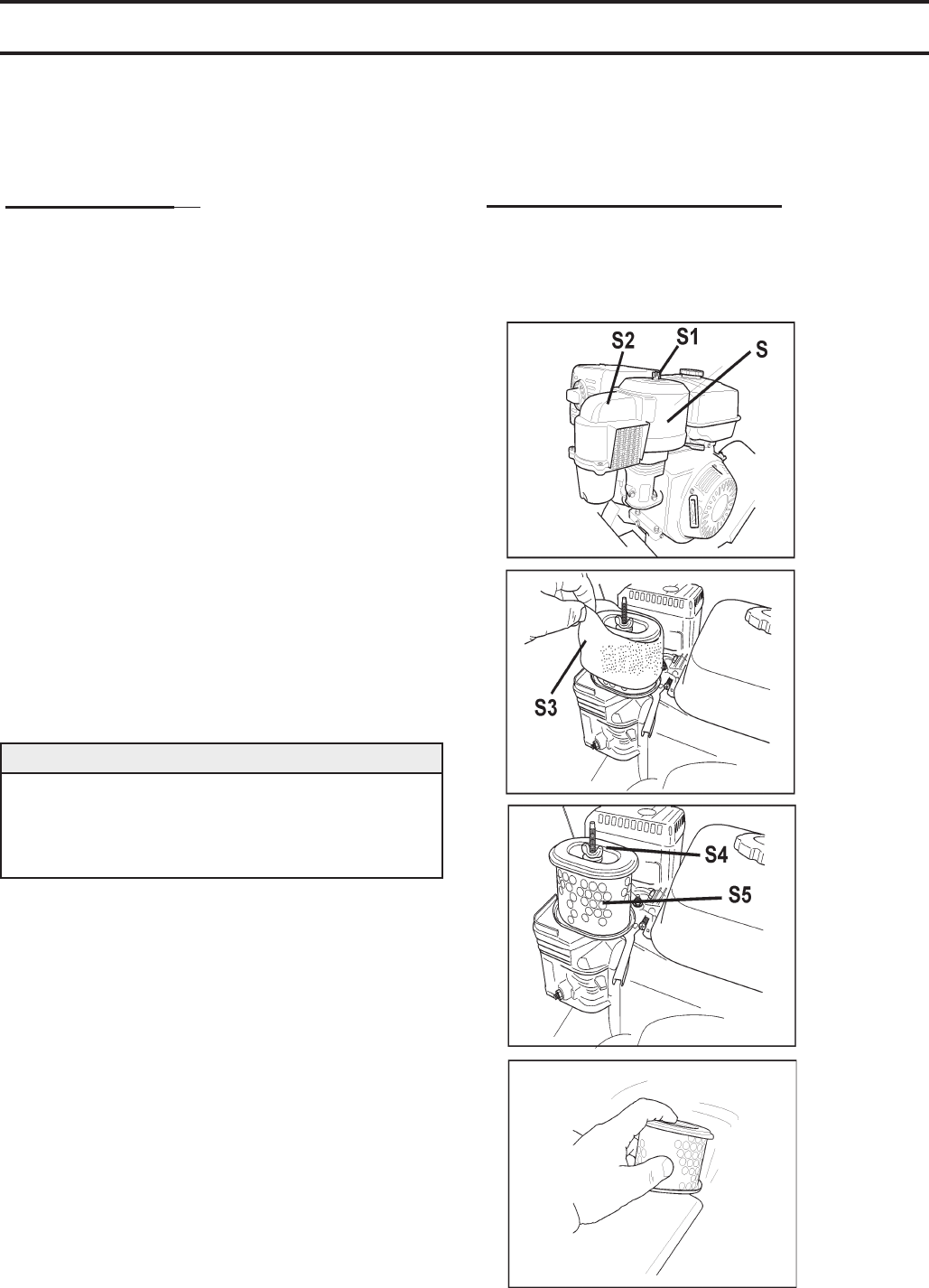

Replacing Engine Air Filter (S):

If the engine seems weak, produces black smoke or runs

unevenly, the air lter may be clogged. For this reason,

it is important to clean and replace the air lter regularly.

Check engine manual for detailed instructions.

Cleaning/replacement of the air lter is carried out as fol-

lows:

1.Undo the wing nut (S1) and lift off the cyclone air lter

cowling (S2).

2.Remove the foam rubber pre-lter (S3) and clean using

a mild detergent. Squeeze it dry with a clean cloth. Soak

it with new engine oil. Squeeze out excess oil.

3.Remove the wing nut (S4) in the air lter and remove

the paper lter (S5). Tap the paper lter against a xed

surface to remove dust. If the paper lter is still dirty or

damaged, it MUST be replaced.

NOTICE

DO NOT use compressed air over 2 bar / 30 PSI to

clean the paper lter.

DO NOT wash paper lter.

DO NOT oil paper lter.

4.Ret the air lter as follows:

Mount the paper lter in the air lter housing and tighten

the wing nut.

5.Ret foam rubber pre-lter (S3) on the paper lter (S5).

6.Ret with the air lter cowling (S2).