32 – English

MAINTENANCE

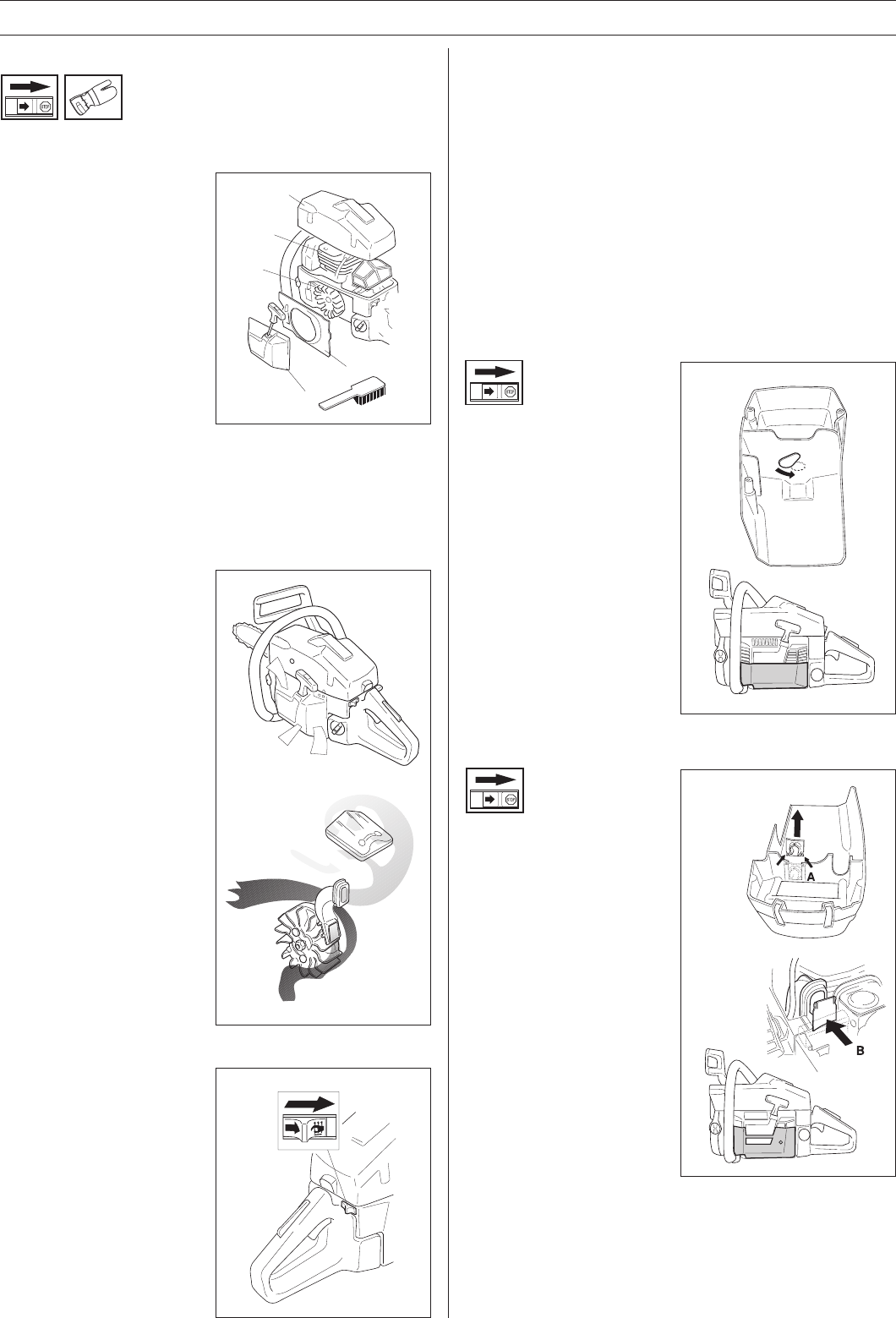

Cooling system

To obtain the lowest possible running temperature the saw is

equipped with a cooling system.

The cooling system

consists of:

1. Air intake on the starter

unit.

2. Air guide plate.

3. Fan blades on the

flywheel.

4. Cooling fins on the

cylinder.

5. Cylinder cowling

(supplies cold air over

the cylinder).

Clean the cooling system with a brush once a week, more often

in demanding conditions. A dirty or blocked cooling system

results in the saw overheating which causes damage to

piston and cylinder.

Winter use

During winter time, powder snow and cold weather can cause

running problems, such as:

• Too low engine temperature.

• Icing on the air filter and carburettor.

Therefore some special measures are required:

• Partly reduce the air inlet of the starter and by doing that

increase the engine temperature.

• Preheat the intake air to the carburettor by removing the

special plug between the cylinder and the carburettor space.

The cylinder cover is made so it can be changed for running in

cold weather. There is a possibility to make a hole in which,

during the warmer part of the year, should be sealed using a

plug.

Temperature 0

o

C (32

o

F) or colder

Model 254: Turn the cover

lid so that the preheated air

from the cylinder can pass

into the carburettor area

preventing for instance icing

on the air filter.

Model 257, 262: Move the

cover from position A to

position B so that preheated

air can pass from the

cylinder to the carburettor

space and prevent forma-

tion of ice in the air filter.

NOTE! When the cover is

placed in the air nozzle it is

important that the air nozzle

seals hermetically to the

cylinder cover.

Temperature -5

o

C (23

o

F) or colder

For running the saw in cold

weather or powder snow, a

special cover is available,

which is mounted on the

starter housing. This

reduces the air flow and

prevents large amounts of

snow from being sucked in.

IMPORTANT! If a special

winter kit is assembled or

measures are taken to

increase the engine

temperature, a readjustment

to normal setting has to be

done when the saw is used

under normal conditions.

Otherwise, there is a risk of

overheating, which can

cause severe engine

damage.

Model 257, 262: When the cover is mounted in position A, it

must be turned with the cut towards the air filter. To make a

proper centrifugal cleaning possible, the air nozzle must seal

hermetically to the crankcase and cylinder cover.

IMPORTANT! Any maintenance other than that described in

this manual must be carried out by your servicing dealer.

On the model XPG both the

front handle and the rear

handle are equipped with

electrical heating coils. These

are supplied with electricity

from a built-in generator in the

electrical system. The switch

for the heating coils is placed

to the right of the rear handle.

When the switch is pushed to

the right, the heat is switched

on. When it is pushed to the

left, the heat is switched off.

Heated handles

1

2

5

4

3

Centrifugal cleaning ”Air Injection”

Centrifugal cleaning means

the following:

All air to the carburettor is

carried through the starter.

Dirt and dust is centrifuged

away by the cooling fan.

IMPORTANT! In order to

keep the function of the

centrifugal cleaning, a

continous maintenance and

care must be made.

• Clean the air intake to the

starter, the fan wings of the

flywheel, the space around

the flywheel, inlet pipe and

carburettor space.

257, 262

254