22 – English

MAINTENANCE

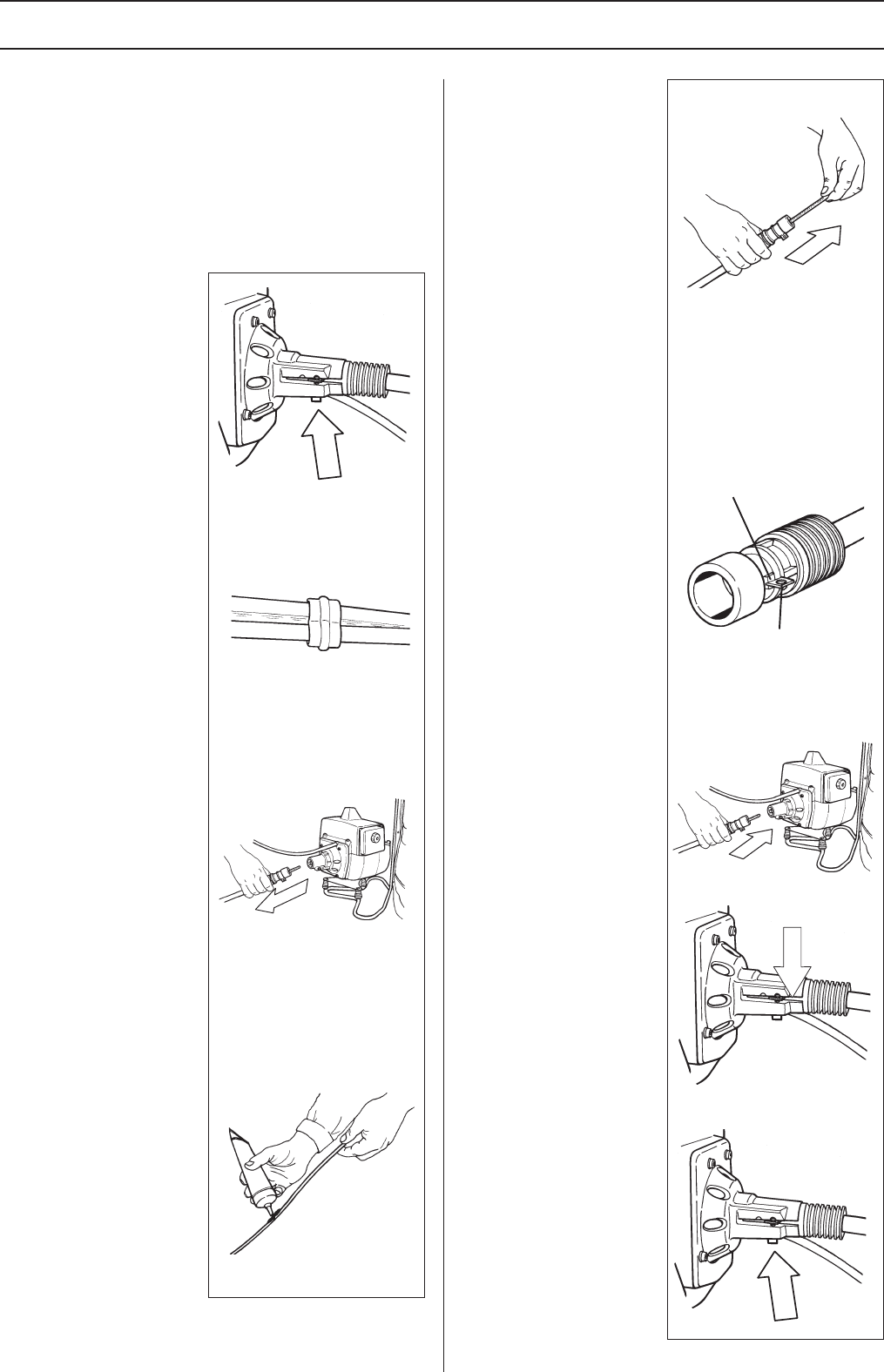

Drive shaft

The flexible drive shaft is lubricated with special grease. The

shaft must be lubricated at least every 25 working hours. A

tube of drive shaft grease is supplied with every machine.

NOTE! Do not use gearbox grease on the drive shaft.

B

A

• Separate the two rig shaft halves (see page 16).

• Remove the bolt that

holds the drive shaft

sleeve in the clutch cover.

• Remove the clip that

holds the throttle cable on

the drive shaft.

• Pull the drive shaft sleeve

out of the clutch cover.

• Remove the drive shaft

from the sleeve either by

shaking it out or pulling it

out using pliers.

• Coat the surface of the

shaft with grease from the

tube. Spread it out using a

brush or rag.

• Slide the drive shaft back

into the sleeve. Make sure

the shaft engages correctly

by turning it and pushing

at the same time.

• When the shaft is correctly

installed in the sleeve the

end of the shaft should

project about 30 mm

beyond the edge of the

sleeve.

• When the sleeve and drive

shaft are installed in the

clutch cover the guide pin

(A) on the sleeve and the

adjustable stop (B) must

be positioned opposite

each other.

• Rotate the shaft and push

it in at the same time.

• Install the drive shaft

sleeve in the clutch cover

so that the stop locates in

the slot on the underside

of the clutch cover.

• Tighten the locking bolt.

NOTE! The bolt must be

inserted in the threaded

half of the cover first, so

that the cover is not drawn

together.