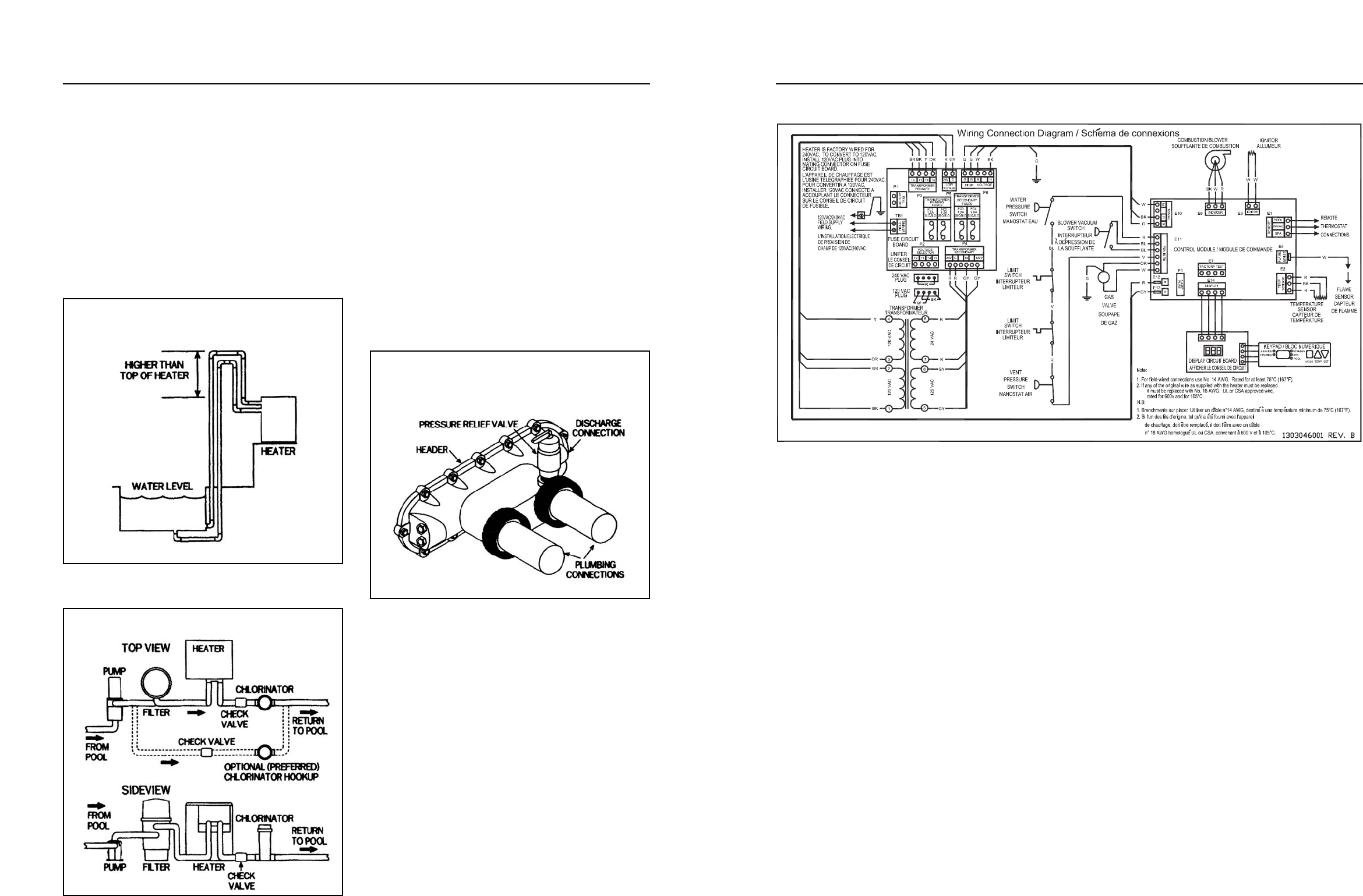

Wiring Diagram Figure 35

Electrical connections:

The heater is equipped with a Hot Surface Ignition

Control System that automatically lights the burners.

An external power supply is required to power the

control system.

The heater comes factory-wired for use with a 240

VAC, 60 Hz, field power supply. To convert the heater

to 120 VAC, 60 Hz, remove the 240 VAC Voltage

Selector Plug from the receptacle on the Fuse Board.

Locate the 120 VAC Voltage Selector Plug and install

it into the receptacle.

All wiring connections to the heater must be made

in accordance with the latest edition of the National

Electrical Code

ANSI/NFP

A

70, unless local code

requirements specify otherwise. In Canada, follow CSA

C22.1 – CANADIAN ELECTRICAL CODE, Part 1.

The heater must be electrically grounded and

bonded in accordance with local codes, or in the

absence of local codes, with National Electrical Code,

ANSI/NFPAA 70.

The H-Series heater must be installed with the

electrical connections, service entry/remote control,

located on the left side of the heater.

Field wiring connections are to be made to the

Fuse Board behind the control access panel. Connect

the field supply wires to the terminal block on the

Fuse Board. Connect the ground wire to the lug adja-

cent to the Fuse Board. Tighten terminal screws to 8

in-lbs.

17

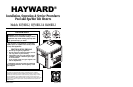

Installation above pool/spa surface:

I

f the heater is installed less than three (3) feet

a

bove the surface of the pool/spa water, install eye-

ball fittings or directional flow fittings on the end of the

return water line to the pool/spa to create adequate

backpressure at the heater to operate the pressure

safety switch when filter pump is running.

If heater is installed more than three (3) feet above

the surface of pool/spa water, install a loop as shown

on Figure 32 to prevent drainage of water in heater

during filter change.

For installation below pool/spa surface, refer to

Section IV.

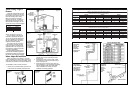

Automatic chlorinators and chemical feeders:

If used, a chlorinator must be installed down-

stream from the heater in the pool return line and at a

lower elevation than the heater outlet connection. See

Figure 33. Install a separate positive seal, corrosion

resistant check valve between the heater outlet and

chlorinator to prevent highly concentrated sanitizers

from back-siphoning into the heater. Back-siphoning

usually occurs when the pump is shut off and a pres-

sure-section differential is created.

Pressure relief valve:

It may be necessary to install a pressure relief

valve to conform with local building codes. A

3

⁄4” pres-

sure relief valve with a discharge capacity greater

than or equal to the BTUH input of the heater and a

pressure relief rating less than the heater working

pressure is recommended (see rating plate).

A

3

⁄4” NPT

connection is provided in the front head

-

er for installation of a pressure relief valve. See

Figure 34. The valve shall be installed directly to the

header in a vertical position.

T

o avoid scalding or

water damage due to relief valve operation, connect

a drain pipe to the valve outlet and run the line to a

safe place of discharge. The drain pipe must be at

least the same size as the valve discharge connec-

tion throughout its entire length and must pitch down-

ward from the valve. No shutof

f valve or restriction

shall be installed between the relief valve and the

discharge of the drain line. The valve lever should be

lifted at least once a year to ensure that the water

-

way is clear.

16

Heater Installation Above Pool

Figure 32

Automatic Chlorinator

Figure 33

Pressure Relief Valve

Figure 34