Troubleshooting Chart

37

Section VII. Troubleshooting

General:

N

OTE:

T

hese instructions are intended for the use

o

f qualified personnel trained and experienced in the

installation and servicing of this type of heating equip-

ment and its related system components. Some

states may require installation and service personnel

to be licensed. Persons not qualified should not

attempt to repair this equipment according to these

instructions.

WARNING: Never leave a jumper wire connected

to keep a heater running. A jumper wire should be

used as a test device only, as it is not a cure for a

defective control.

CAUTION: Never allow the main burner to operate

more than five seconds with the filter system shut off.

Serious damage to the heater will result. Anytime the

heater bangs or knocks, it indicates a water void or

lack of water flow. Shut off heater immediately if this

occurs.

Wiring:

As a preliminary check, make sure that all wire

connections are clean and tight and that all wiring

conforms to the wiring diagrams See Figures 35

and 36.

Automatic Reset Time

The heater will automatically reset when an error

condition is corrected and resume operation as

detailed in the table below. The heater can be manu-

ally reset using the keypad by cycling the mode but-

ton through “STANDBY” and back to the original

operating mode (“SPA” or “POOL”).

Error Codes (See chart on page 44)

“LO” Error Code

The V

ersion 13 ignition control features revised

logic for the “LO” error code. The “LO” error code indi-

cates that the contacts on one or more of the switches

in the limit string are open. The limit string contains the

temperature limit switches (2), the vent pressure

switch, and the water pressure switch. If the limit string

opens the error code “LO” will be displayed. There are

two types of “LO” error (note there is no differentiation

between the types on the display):

1. “Soft” lockout

When an “LO” error is displayed without a call for

heat the control will accept keypad inputs to change the

mode, adjust the temperature set points, enter bypass

operation, or change from °F to °C. The heater will not

operate until the error code is cleared. When the error

code is cleared the heater will remain in the selected

mode and retain any new temperature set points. If

power is interrupted the heater will retain the selected

mode and set points. If there is a call for heat “soft”

lockout will end and the control will enter “hard” lockout.

2. “Hard” lockout (Safety lockout)

When an “LO” error is displayed and a call for heat

is present the control will enter “hard” lockout (safety

lockout). The control will only accept keypad inputs to

change the mode (to place the heater into “STANDBY”

or to reset the control). The heater will not operate until

the error code is cleared or the call for heat is removed.

When the error code is cleared the heater will remain in

the selected mode. If power is interrupted the heater

will retain the selected mode in memory.

During a pre-install prior to pool/pump startup the

heater will display the “LO” error code because the

water pressure switch contacts will be open. This will be

a “soft” lockout if the heater remains in “STANDBY”

mode or if there is no call for heat in “SPA” or “POOL”

modes. If the temperature of the heater is below the

factory set points of 65° F, changing the mode from

“STANDBY” to “SPA” or “POOL” will generate a call for

heat and the control will go into a “hard” lockout. The

error code “LO” will be displayed and the control will

only accept keypad inputs for mode change until the

error code is cleared.

Supply Wiring

If the heater is connected to the line side of the cir-

cuit it will be powered at all times. In this situation, when

the pump shuts down the heater will display a fault

code of “LO”. If there is a call for heat and the pump

then re-starts there will be a 2-minute delay for the

heater to fire. After the pump has been running for at

least 2 minutes there is no delay for heater operation.

Wiring the heater to the load side of the timer or con-

troller will not result in a 2-minute delay if the pump primes

quickly enough to activate the heater’

s water pressure

switch. If the pump is slow to prime the heater may dis-

play an “LO” fault code and will take 2 minutes to auto-

matically restart. If the pump has primed, this wait can be

avoided by manually clearing the error code via the key-

pad by changing the mode through the “STANDBY” set-

ting and returning to the initial setting (“SPA” or “POOL”).

When a heater is wired to the line side of the power cir

-

cuit (continuous power) the blower will not operate when

the pump is cycled via a time clock or other switch method.

Internal Wiring

If the heater display is blank after the electrical has

been installed check the ribbon cable from the display

board leading to the ignition control board.

This cable is

not polarized and can be inserted upside down if it was

removed when electrical was done. Invert the cable on

the connector pin and see if the display is now on. The

display may read ‘CE’. If it does, remove power from

the heater for 1 minute and then re-connect the power

.

36

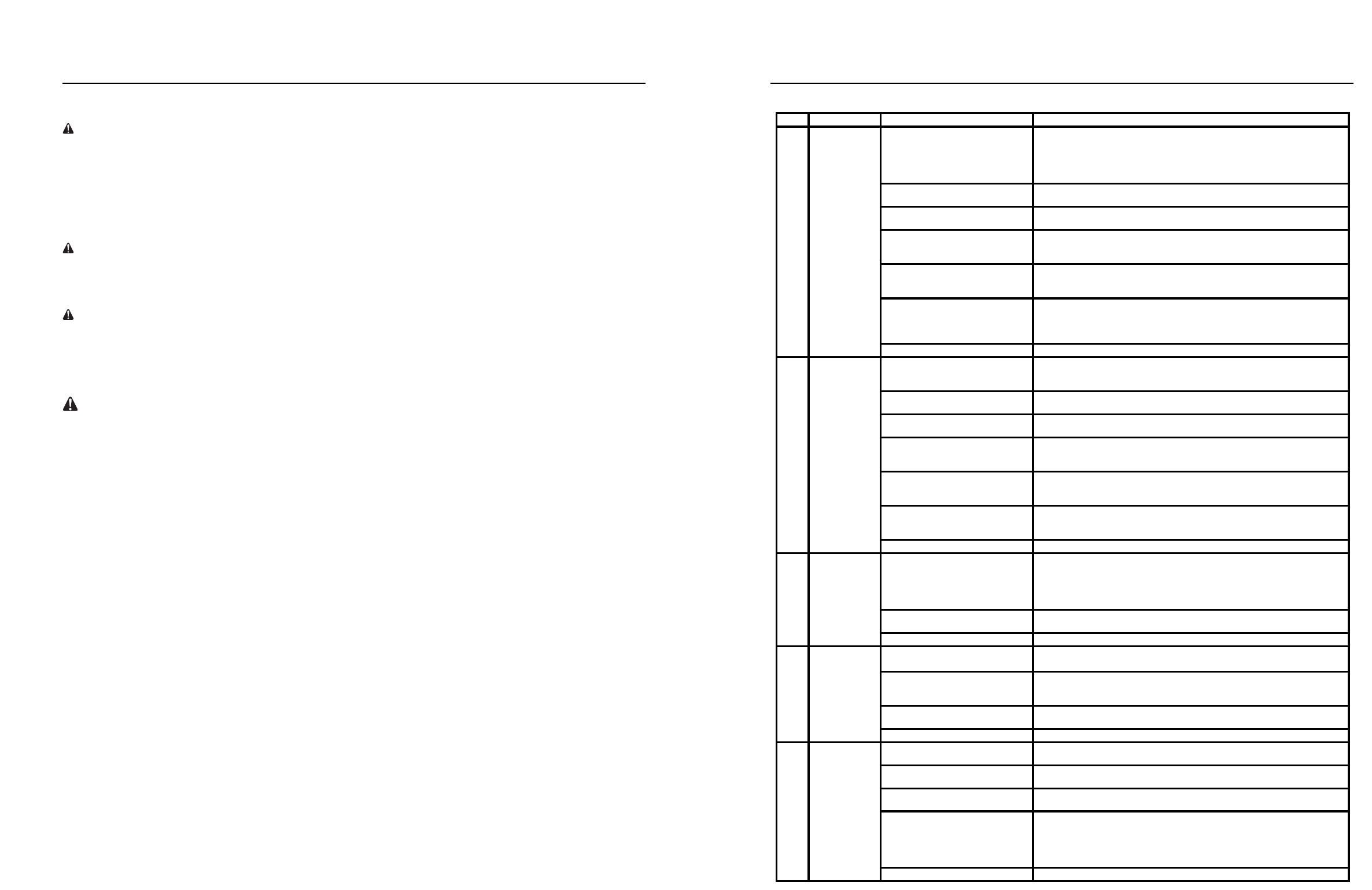

Code Fault Diagnosis Step Remedy

1. Check for Low & High Voltage Output

from Fuse Board

Disconnect plug from P5 connector from Fuse Board. Measure for 24vac between

pins of receptacle on Fuse Board. Reconnect plug. Disconnect plug form P6 of Fuse

Board. Measure for 120vac between pin 3 and 6 of receptacle on Fuse Board.

Reconnect plug. If OK, proceed to section titled "Low voltage circuit fault". Otherwise,

proceed to step 2.

2. Ensure field power supply to heater is

turned on.

Measure for field supply voltage across terminals of TB1 terminal block on Fuse

Board. If OK, proceed to step 3.

3. Check for faulty Fuse Board wiring.

Inspect Fuse Board wiring. Ensure all plugs are securely fastened to Fuse Board. If

OK, proceed to step 4.

4. Verify that FC1and FC2 Fuses on

Fuse board are not open.

Remove FC1 and FC2 fuses from fuseholder. Measure continuity across fuse. If

fuses are open, proceed to section titled "Open FC1 and/or FC2 Fuses". If fuses are

OK, reinstall them and proceed to step 5.

5. Verify that 240vac Voltage Selector

Plug is not installed with a 120vac field

power supply.

Check that proper Voltage Selector Plug is installed in Fuse Board. If OK, proceed to

step 6.

6. Check for defective Transformer.

Disconnect plug from P4 connector from Fuse Board. Measure for 24VAC between

pins 1 & 2 of plug of Transformer and for 120VAC between pins 4 & 6. If 24VAC or

120VAC is not present, replace Transformer. Otherwise, proceed to step 7.

7. Fuse Board is defective Replace Fuse Board.

1. Check for Low Voltage Output from

Fuse Board

Disconnect plug from P5 connector from Fuse Board. Measure for 24vac across

pins. Reconnect plug. If OK, proceed to step 2. Otherwise proceed to step 5.

2. Check for faulty Control Module

wiring.

Inspect Control Module wiring. Ensure all plugs are securely fastened to Control

Module. If OK, proceed to step 3.

3. Verify low voltage input to Control

Module.

Verify 24vac across R and C terminals on Control Module. If not OK, replace

harness. If OK, proceed to step 4.

4. Verify that F1 Fuse on Control Module

is not open.

Remove F1 fuse from fuseholder. Measure continuity across fuse. If OK, replace

Control Module. If fuse is open, proceed to section titled " Open FC3 or F1 Fuse".

5. Verify that FC3 on Fuse Board is not

open.

Remove FC3 fuse from fuseholder. Measure continuity across fuse. If fuse is open,

proceed to section titled "Open FC3 and/or F1 Fuses". If OK, reinstall fuse and

proceed to step 6.

6. Check for defective Transformer.

Disconnect plug from P4 connector from Fuse Board. Measure for 24VAC between

pins 1 & 2 of plug from transformer. If 24VAC is not present, replace Transformer.

Otherwise, proceed to step 7.

7. Fuse Board is defective Replace Fuse Board.

1. Verify that 120vac Voltage Selector

Plug is not installed in with a 240vac

field power supply.

Check that proper Voltage Selector Plug is installed. If OK, proceed to step 2.

If 120VAC plug is installed and field supply voltage is 240VAC, FC1 and FC2 fuses

will have opened. Install the correct Voltage Selector Plug and new FC1 and FC2

fuses.

2. Check for faulty Transformer wiring.

Inspect Transformer wiring. Ensure insulation on wiring is not worn. If OK, proceed to

step 3.

3. Defective Transformer Replace Transformer

1. Check for faulty Gas Valve wiring.

Inspect Gas Valve wiring. Ensure insulation on wiring is not worn. If OK, proceed to

step 2.

2. Verify that Gas Valve is not defective

Measure for resistance across Gas Valve terminals and between each terminal and

ground. If short exists, replace Gas Valve. If OK, proceed to step 3.

3. Check for faulty Control Module

wiring.

Inspect Control Module wiring. Ensure insulation on wiring is not worn. If OK, proceed

to step 4.

4. Control Module is defective. Replace Control Module.

1. Check for faulty Igniter wiring.

Inspect Igniter wiring. Ensure insulation on wiring is not worn. If OK, proceed to step

2.

2. Check for faulty Blower wiring.

Inspect Blower wiring. Ensure insulation on wiring is not worn. If OK, proceed to step

3.

3. Check for defective Igniter.

Disconnect Igniter plug from Control Module. Measure resistance across Igniter. If

shorted, replace igniter. IF OK proceed to step 4.

4. Check for defective blower.

Disconnect blower plug from Control Module. Measure resistance across blower

windings. Winding resistance across lead should be in the following range: Black-to-

White: 10 to 14 ohms, Red-to-White: 18 to 22 ohms. If measured values vary

substantially from these values, blower is defective. Replace. Otherwise, proceed to

step 5.

5. Control Module is defective. Replace Control Module.

None Open FC4 Fuse.

None

Open FC1 and/or

FC2 Fuses.

None

Open FC3 and/or

F1 Fuses.

None

Heater will not

power-up.

None

Low voltage circuit

fault.

I

DL Heater Diagnostic Guide