5. Turn on water system and start heater follow

ing the lighting instructions on the label inside

the cabinet. If there is more than just the

pool/spa heater connected to the gas supply

line, turn each of those appliances on while

testing the heater.

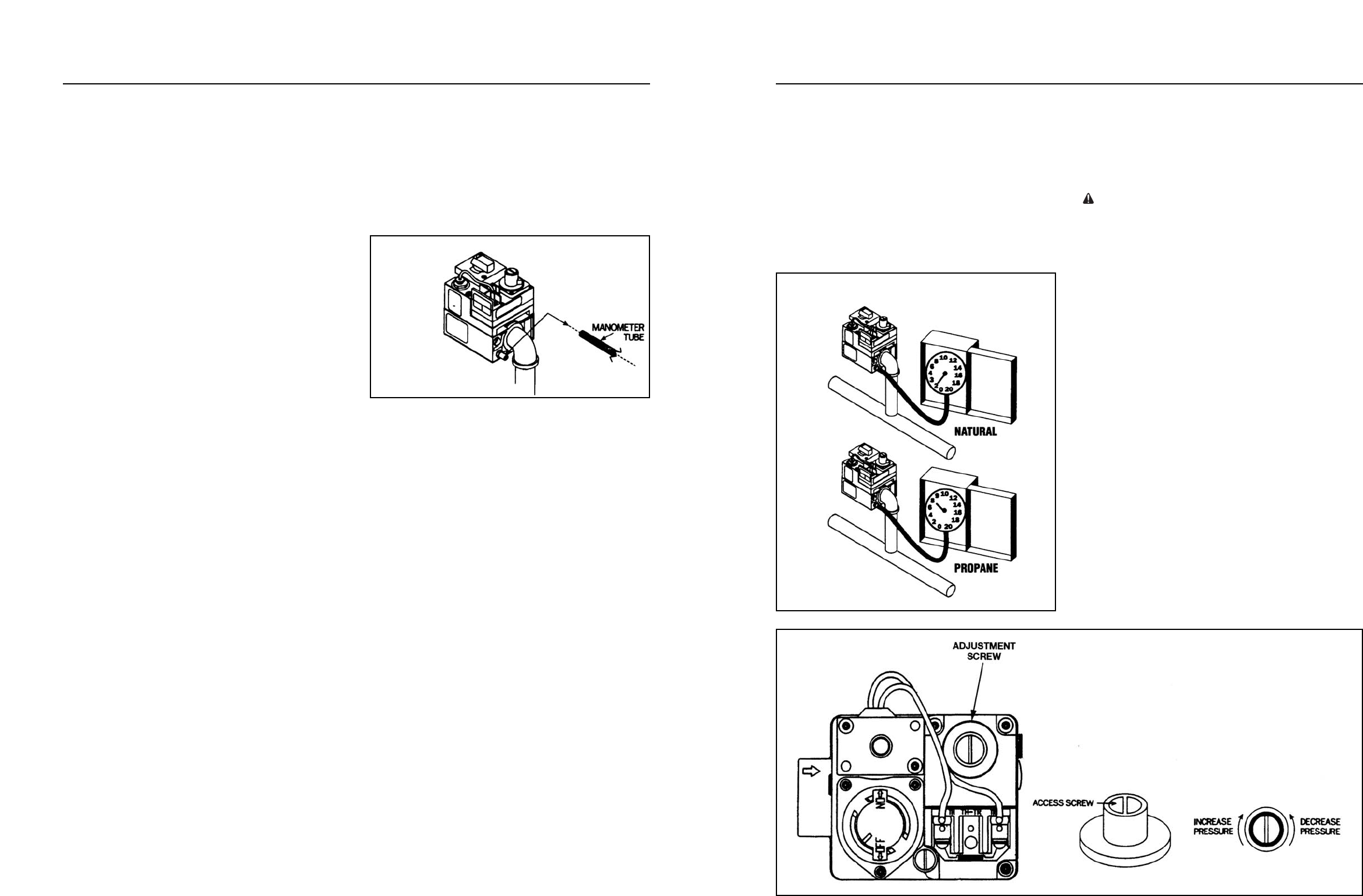

6. Take pressure reading with the heater running.

Propane gas must have 7” W.C. (water

column pressure). Natural gas must have 2”

W.C. See Figure 38.

7. If the gas pressure does not meet the above

requirements the regulator must be adjusted.

B. Gas pressure regulator adjustment procedure:

1. Remove access screw from the pressure

regulator.

2. Turn regulator adjustment screw clockwise to

increase pressure and counterclockwise to

decrease pressure. Replace access screw.

See Figure 39.

SAFETY WARNING: Do not remove the

1

⁄8” pipe

nipple with the valve in the “ON” position. The valve

must be in the “OFF” position when the plug is

remove.

3. Remove the

1

⁄8” pipe nipple and replace

1

⁄8”

plug. If proper pressure cannot be achieved

by adjusting the regulator, the installer must

contact the gas supplier and request that the

inlet pressure to the heater be set as follows:

Natural gas – 7” W.C., Propane gas – 11”

W.C. The inlet gas pressure must not exceed

10.5” W.C. (water column pressure) for

Natural gas or 13 W.C. for Propane gas.

Exposure to higher pressures can damage

the gas control valve, causing leaks or

diaphragm rupture. This damage could result

in fire, explosion, or burner overfiring leading

to carbon monoxide poisoning. Minimum inlet

gas pressure is 4.5” W.C. for Natural and 9”

W.C. for Propane for the purpose of input

adjustment.

21

Section IV. Installer Check-out And Start-up

General:

S

ome of the following procedures will require the

h

eater to be operating. Full lighting and shutdown

instructions are included on the lighting instructions

label secured inside the cabinet. The heater is auto-

matically lit on each call for heat.

Water must be flowing through the heater during

operation. Check that the pump is operating and the

system is filled with water and purged of all air prior

to starting heater.

Gas line testing:

The appliance and its gas connection must be leak

tested before placing the appliance in operation. The

heater and its individual shutoff valve must be discon-

nected from the gas supply piping system during any

pressure testing of that system at test pressures in

excess of

1

⁄2 psig (3.45 kPa). The heater must be iso-

lated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pres-

sure equal to or less than

1

⁄2 psig (3.45 kPa).

Gas supply line must be capped when not con-

nected. After pressure testing, reconnect the gas pip-

ing to the gas valve. Turn gas supply on and test all

pipe and tubing joints for leaks. Use a soap and water

solution. Bubbles forming indicate a leak. Never use

a open flame (match, lighter, torch, etc.) as a leak

could cause an explosion or injury. Shut off gas

and fix even the smallest leak right away. Be sure to

leak test manifold fittings using above procedure once

heater is in operation.

Gas pressure test procedure:

The following gas pressure requirements are

important to the proper operation of the burners in

gas heaters. Improper gas pressure or gas volume

will create the following conditions:

1. Flame burns totally yellow.

2.

Flame lifts off burner.

3. Heat exchanger soots up.

The pressure regulator on all H-Series heaters is

preset at the factory and normally needs no adjust-

ment. If gas pressure is inadequate, check for under

-

size piping between meter and heater or for low

capacity gas meter.

A. Gas pressure test procedure:

1. Obtain necessary equipment:

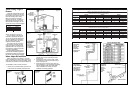

a. Manometer to read pressure in inches of

water column.

b. 1/8” nipple (1/8” pipe thread x 1” long).

c. 3/16” Hex Wrench.

d. Screwdriver

.

SAFETY WARNING: Do not remove the

1

⁄8” plug with

the gas valve in the “ON” position. The gas valve

must be in the “OFF” position when the plug is

removed.

2. Remove

1

⁄8” plug from gas valve.

3. Install

1

⁄8” pipe nipple into gas valve.

4. Attach manometer to the ” pipe nipple.

See Figure 37.

20

G

as Pressure

Figure 37

Gas Pressure Reading

Figure 38

Valve Adjustment Screw

Figure 39