7 -28

23.Place equal amount of shims and a shellacked

gasket on each axle housing. Install L.H. axle

housing and differential assembly in tractor. Secure

axle housing to tractor.

24.Install R.H. axle housing on tractor, being sure the

shifting clutch fits on the shifting gear. Secure axle

housing to tractor. Torque bolts to 45 ft-lbs

(61 Nm).

25.Remove the engine and high-low planetary or the

advance casting and the forward-reverse

planetary.

26.Using a screwdriver or similar tool, check the

differential assembly for play. Running clearance

should be .008" - .012". Adjust by adding or

removing an equal amount of shims from each axle

housing.

27.Adjust axles for .008" - .012" end play. Add or

remove shims behind the bearing cap.

7.8 POWER TAKE OFF (PTO)

If it becomes difficult to shift the power takeoff in and

out of gear, check external linkage for binding.

To examine the PTO, remove attachment boss plate on

the front of advance casting. At this point the dog gear

and shifting eccentrics are exposed (Figure 30).

Proceed as follows:

1. Check the dog block for wear.

2. Examine shifter shaft for wear.

3. For closer inspection of the shifter assembly,

remove the assembly by removing jam nut inside

of advance casting and then removing the shoulder

bolt.

4. Inspect shifter body and its components for

damage.

5. Check for bearing failures.

6. Examine pinion shaft for twisting.

7. Replace worn or damaged parts.

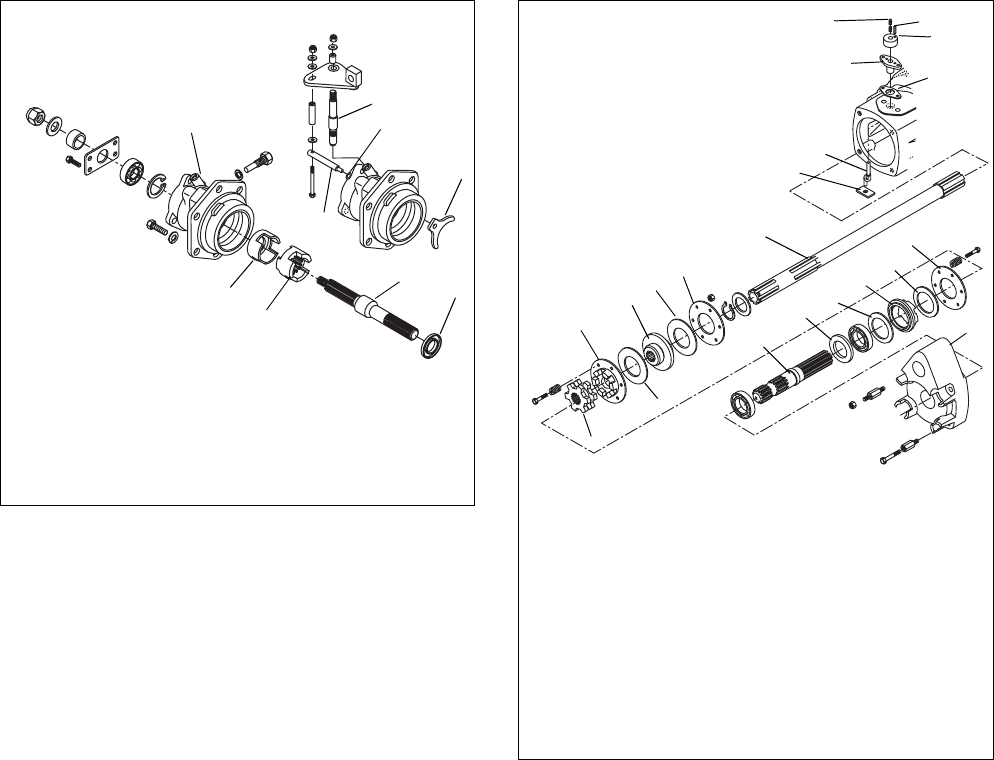

Figure 28

1. Stationary Pivot

2. O-Ring

3. Shifting Yoke

4. Clutch Sliding Pin

5. Straight Axle

6. Seal

7. Shifting Clutch

8. Stationary Clutch

9. 2-Speed Axle Housing

4-Speed Right Hand Axle

1

2

3

4

5

6

7

8

9

Figure 29

1. Back Plate

2. Brake Disc

3. Dog Plate Brake

4. Trunnion Block

5. Seal

6. Quick Hitch Shaft

7. Quick Hitch Casting

8. Dog

9. Friction Washer

10.Dog Plate

11.Drive Plate

12.Friction Washer

13.Back Plate

14.PInion Shaft

15.Shipper Shaft

16.Shipper Shaft Gasket

17.Shipper Shaft Body

18.Shipper Shaft

19.Set Screw

20.Roll Pin

1

2

3

2

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

4

20