5 -16

5.2 CHECKING ENGINE OIL

Check the engine oil daily prior to use.

IMPORTANT:

Never operate the engine with the oil

below the low mark on the dipstick.

See the engine manual for oil specifications and oil

filter service instructions.

To check oil level:

1. Move the unit to level location.

2. Clean around the dipstick and filler tube to prevent

dirt from entering the engine.

3. Remove the dipstick and wipe off the oil on the

depth stick.

4. Put the dipstick back into the engine, and remove

again.

5. When the dipstick is removed, note the oil level. Oil

should be between the full and add mark.

6. Replace dipstick.

7. If required, add 5W30 below 40

o

or 30W above

40

o

. Do not overfill.

8. Clean up any spillage that may have occurred.

5.3 CHANGING OIL

Engine muffler and other parts will be hot if unit has

been running.

1. Engine oil should be changed after the first five

hours of operation and every 25 hours there after.

2. Move the unit to a level, well ventilated area and

set the parking brake.

3. If the engine is cold, let the unit run for five

minutes.

4. When the engine is warm, stop the engine.

5. Clean the area around the dipstick and drain.

6. Put an open container that will hold one gallon of

oil under the drain.

7. Open the drain.

8. Allow the engine oil to drain completely into the

one gallon container. Remove container and

contents for future recycling as required.

9. Close the oil drain.

10.If used; remove the oil filter.

11.Clean the oil filter port and install a new oil filter

according to the instructions on the oil filter. Fill

with new oil to the "full" mark on the dipstick.

12.Start and run the engine for one minute. Stop the

engine and recheck the oil level and add as

necessary.

13.Check for leakage at the drain plug and oil filter if

used. Tighten the fittings as necessary if leakage

occurs.

14.Release the parking brake.

15.Return the unit into service.

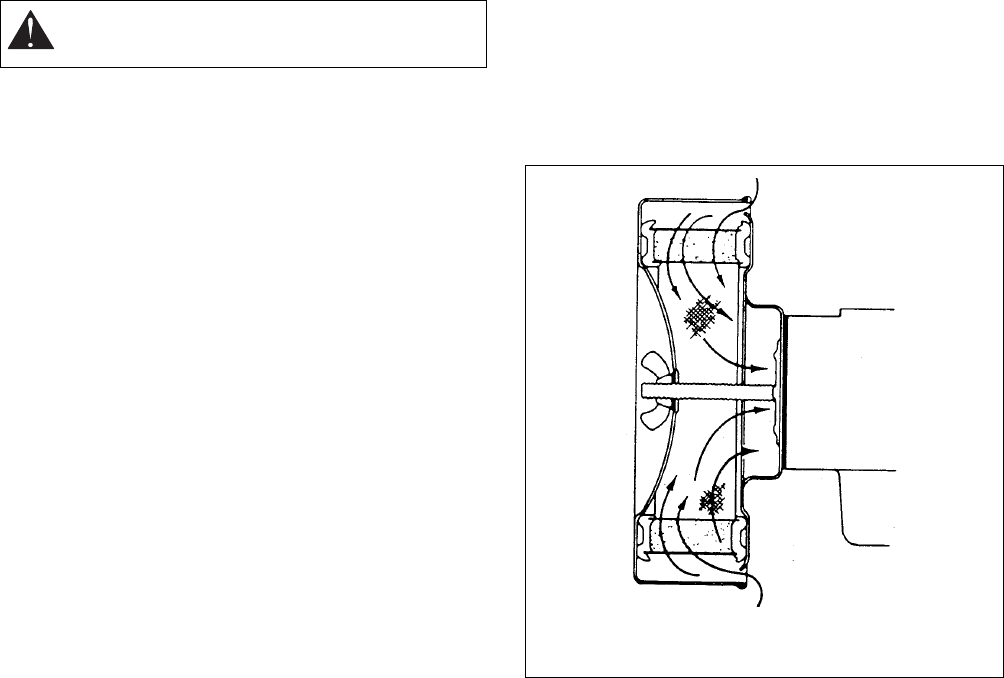

5.4 AIR CLEANER

Dry type air cleaner elements should be replaced after

100 to 200 hours if engine is normally operated under

good clean air conditions. Service and replace element

more frequently under dusty or dirty conditions.

To clean the element remove and tap lightly on a flat

surface to remove loose surface dirt. Replace element

if dirt does not drop off easily. Do not wash or dry

elements in any liquid or attempt to blow dirt off with air

hose as this will puncture the filter element.

Carefully handle new element. Do not use if gasket

surfaces are bent or twisted. Check the following when

installing new element (Figure 9).

1. Back plate must be securely tightened to

carburetor. Replace back plate if bent or cracked.

2. Gasket surfaces of element must be flat against

back plate and cover to seal effectively.

3. Washer must be in place between cover and wing

nut to seal and prevent unfiltered air from entering

through hole in cover. If washer is not used, make

sure wing nut (special) properly seals area around

cover hole.

4. Wing nut must be finger tight.

WARNING:

Do NOT touch parts which are

hot. Allow parts to cool before servicing.

Figure 9