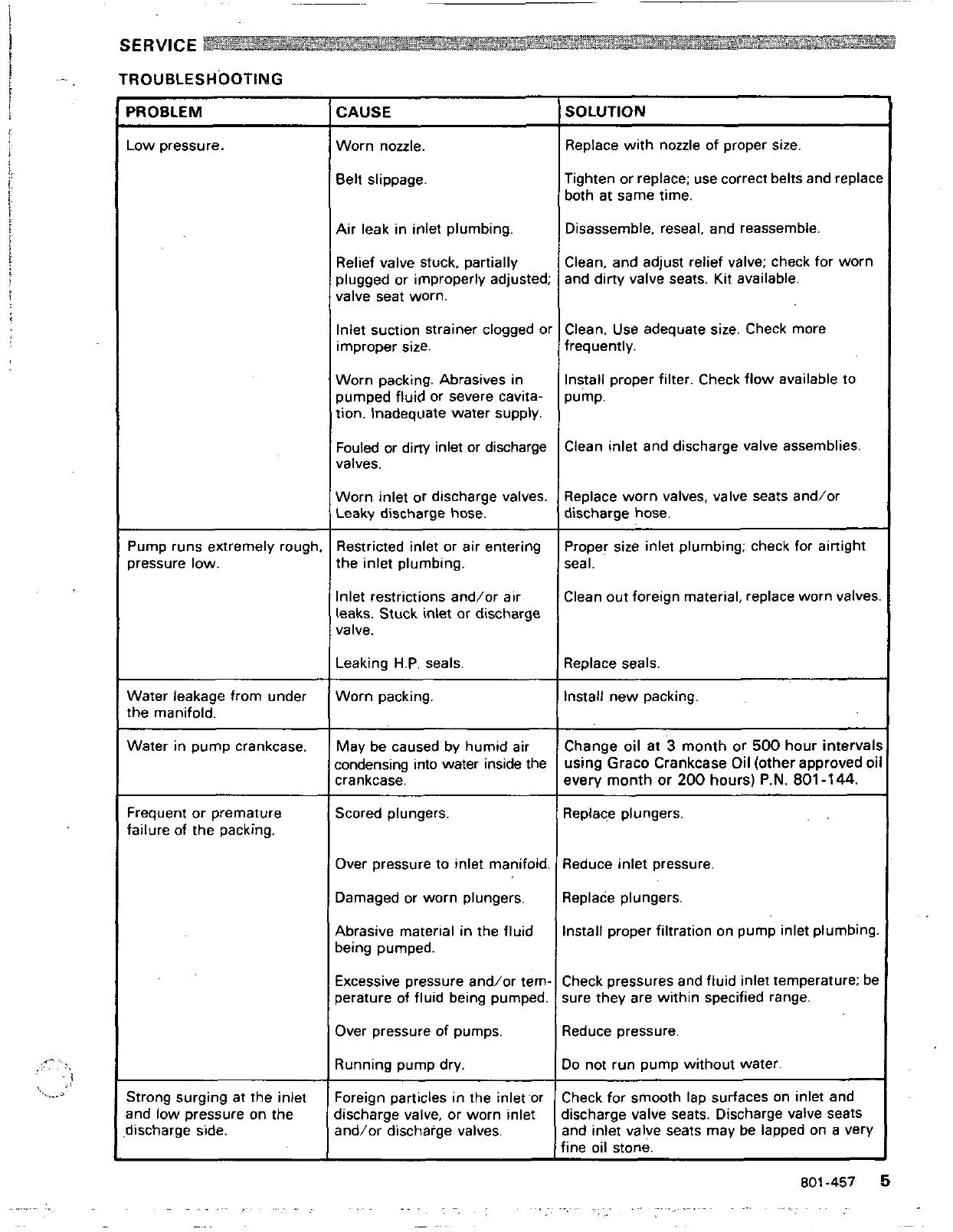

PROBLEM

Low pressure.

Pump runs extremely rough,

uressure low.

Water leakage from under

the manifold.

Water in pump crankcase.

Frequent or premature

failure of the packing.

Strong surging at the inlet

3nd low pressure on the

jischarge side.

CAUSE

Worn nozzle.

Belt slippage.

Air leak

in

inlet plumbing.

Relief valve stuck, partially

valve seat worn.

plugged or improperly adjusted

Inlet suction strainer clogged

o

improper size.

Worn packing. Abrasives in

pumped fluid or severe cavita-

tion. Inadequate water supply.

Fouled or dim/ inlet or discharge

valves.

Worn inlet or discharge valves.

Leaky discharge hose.

Restricted inlet or air entering

the inlet plumbing.

Inlet restrictions and/or air

valve.

leaks. Stuck inlet or discharge

Leaking

H.P.

seals.

Worn packing.

condensing into water inside the

May

be caused by humid air

crankcase.

Scored plungers.

Over pressure to inlet manifold

Damaged or worn plungers.

Abrasive material

in

the fluid

being pumped.

Excessive pressure and/or tern

perature of fluid being pumped.

Over pressure of pumps.

Running pump dry.

Foreign particles

in

the inlet or

discharge valve, or worn inlet

and/or discharge valves.

SOLUTION

Replace

with

nozzle of proper size.

Tighten or replace; use correct belts and replac

both at same time.

Disassemble, reseal, and reassemble.

Clean. and adjust relief valve; check for worn

and dirty valve seats. Kit available.

Clean.

Use

adequate size. Check more

frequently.

Install proper filter. Check flow available to

pump.

Clean inlet and discharge valve assemblies.

Replace worn valves, valve seats and/or

discharge hose.

Proper size inlet plumbing; check for airtight

seal.

Clean out foreign material, replace worn valve:

Replace seals.

Install new packing.

Change oil at

3

month or

500

hour interval

using Graco Crankcase

Oil

(other approved

o

every month or

200

hours)

P.N.

801-144.

?eplace plungers.

?educe inlet pressure.

3eplace plungers.

nstall proper filtration on pump inlet plumbing

:heck pressures and fluid inlet temperature; bc

jure they are within specified range.

?educe pressure.

10

not run pump without water.

:heck for smooth lap surfaces on inlet and

iischarge valve seats. Discharge valve seats

md inlet valve seats may be lapped on

a

very

ine oil stone.