SSeeccttiioonn 77

DDIIAAGGNNOOSSTTIICC TTEESSTTSS

Short to Ground:

4. Set the VOM to measure resistance. Connect the positive (+)

test lead to the case housing of the BCR. Connect the negative

(-) test lead to an outer terminal. “Infinity” should be measured.

Now connect the negative test lead to the BCR center terminal.

“Infinity” should be measured. Next, connect the negative test

lead to the remaining outer BCR terminal. Once again “Infinity”

should be measured.

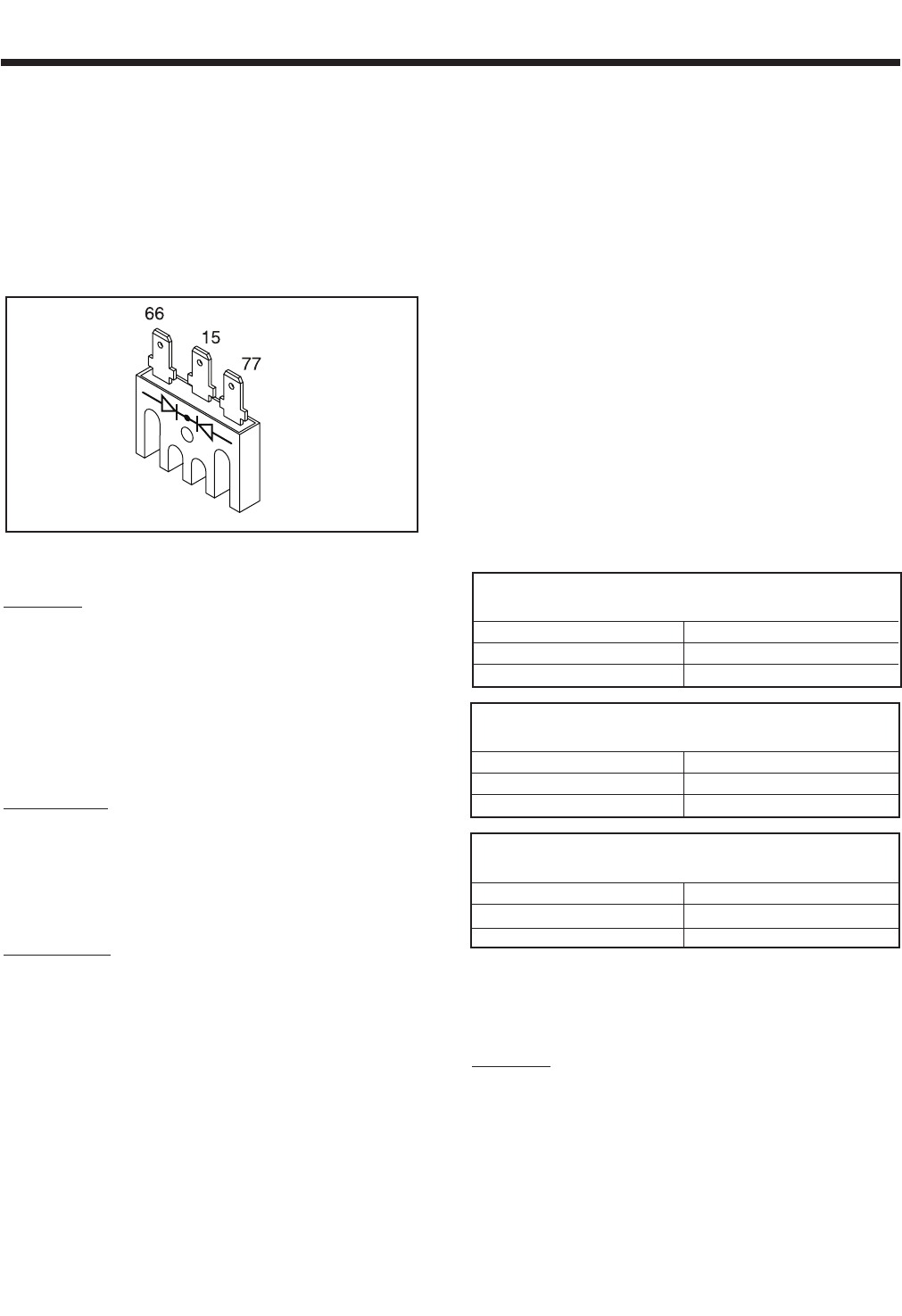

Figure 7-10. – Battery Charge Rectifier

RESULTS:

1. If any of the previous steps has failed, replace the Battery

Charge Rectifier.

2. If the BCR tests good, go to Test 17.

TEST 17 - CHECK BATTERY CHARGE

WINDINGS / BATTERY CHARGE RESISTOR

DISCUSSION:

The Battery Charge Winding (BCW) produces AC

voltage that is delivered to the Battery Charge

Rectifier. The Battery Charge Winding is a center

tapped winding consisting of the following Stator

Leads: Wire 66, Wire 77 and Wire 55. The Battery

Charge Resistor is used as a current limiting resistor.

PROCEDURE:

1. Disconnect the Stator Leads (Wire 66 and Wire 77) from the

Battery Charge Rectifier. (Be sure to disconnect Stator Lead

Wire 66 “Black” from Wire 66 “Blue” connector for this test).

Disconnect the Stator Lead Wire 55 from the Battery Charge

Resistor.

2. Set the VOM to measure resistance at the “R x 1” scale.

Connect one test lead to Stator Lead Wire 66. Connect the

other test lead to Stator Lead Wire 55. Normal Battery Charge

Winding resistance should be measured.

3. Connect one test lead to Stator Lead Wire 77. Connect the

other test lead to Stator Lead Wire 55. Normal Battery Charge

Winding resistance should be measured.

4. Connect one test lead to Stator Lead Wire 55. Connect the

other test lead to Stator Leads Wire 11 & 33 at the back of

CB1. “Infinity” should be measured.

5. Connect one test lead to Stator Lead Wire 55. Disconnect

Stator Lead Wire 2 from the DPE circuit breaker (CB3) and

connect the other test lead to Wire 2. “Infinity” should be mea-

sured.

6 Connect one test lead to Stator Lead Wire 55. Connect the

other test lead to frame ground. “Infinity” should be measured.

7. Connect one test lead to the Battery Charge Resistor terminal

that Wire 55 was removed from. Connect the other test lead to

frame ground. One (1) ohm should be measured. If 1 ohm was

not measured, remove Wire 0 from the Battery Charge

Resistor. Connect one test lead to Wire 0 and the other test

lead to frame ground.

“

Continuity” should be measured. Repair

or replace Wire 0 if defective and retest the Battery Charge

Resistor.

BATTERY CHARGE WINDING RESISTANCE *

QP55 (Model 4702/4703)

AACCRROOSSSS WWIIRREESS:: OOHHMMSS

55 & 66 0.100Ω − 0.116Ω

55 & 77 0.100Ω − 0.116Ω

BATTERY CHARGE WINDING RESISTANCE *

QP65 (Model 4704/4705)

AACCRROOSSSS WWIIRREESS:: OOHHMMSS

55 & 66 0.104Ω − 0.120Ω

55 & 77 0.087Ω − 0.101Ω

BATTERY CHARGE WINDING RESISTANCE *

QP75 (Model 4706/4707)

AACCRROOSSSS WWIIRREESS:: OOHHMMSS

55 & 66 0.092Ω − 0.107Ω

55 & 77 0.076Ω − 0.088Ω

* Resistance values In ohms at 20° C. (68° F.). Actual readings

may vary depending on ambient temperature. A tolerance of plus

or minus 5% is allowed.

RESULTS:

1. For Steps 2 & 3, keep in mind that the resistance values are

very low. Depending upon the quality of the VOM, it may read

“

Continuity” across these windings. Exercise good judgement

with these values.

2. If Steps 2, 3, 4, 5 & 6 fail any test, replace the Stator.

Page 46