14

Cranking Conditions

The following notes apply during cranking cycle.

1. Starter motor will not engage within five (5) seconds of the

engine shutting down.

2. The fuel output will not be energized with the starter.

3. The starter and magneto outputs will be energized together.

4. Once the starter is energized the control board will begin look-

ing for engine rotation. If it does not see an RPM signal within

three (3) seconds it will shut down and latch out on RPM

sensor loss.

5. Once the control board sees an RPM signal it will energize the

fuel solenoid, drive the throttle open and continue the crank

sequence.

6. Starter motor will disengage when speed reaches starter

dropout.

7. If the generator does not reach 2200 RPM within 15 seconds,

re-crank cycle will occur.

8. If engine stops turning between starter dropout and 2200

RPM, the board will go into a rest cycle for seven (7) seconds

then re-crank (if additional crank cycles exist).

9. Once started, the generator will wait for a hold-off period

before starting to monitor oil pressure and oil temperature

(refer to the Alarm Messages section for hold-off times).

10. During Manual start cranking, if the Mode switch is moved

from the Manual position, the cranking stops immediately.

11. During Auto mode cranking, if the remote start contacts OPEN

(OFF), the cranking cycle does NOT abort but continues until

complete. Once the engine starts, it will run for one (1) min-

ute, then shut down.

3.3.4 REMOTE START OFF

Initial Condition: Generator supplying power to customer load.

Once the contacts open, the controller will run the engine through

a one (1) minute cool down period and then shut down.

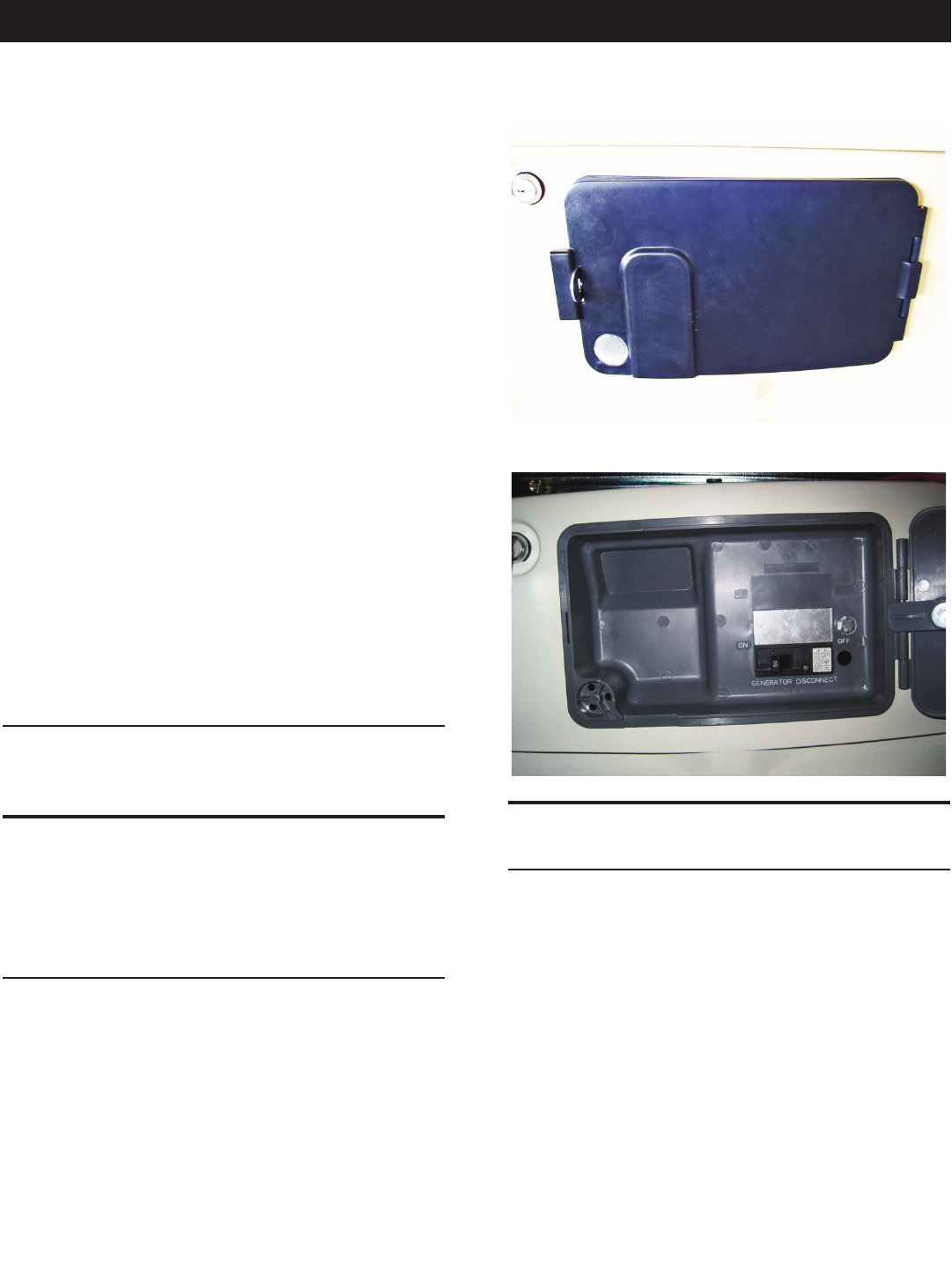

3.4 SIDE COMPARTMENT

(FIGURES 3.2 & 3.3)

Local codes may require this compartment to be locked. A hasp is

provided so the owner can secure the compartment with their own

padlock. Check local codes in the area.

3.4.1 MAIN CIRCUIT BREAKER

This is a 1-pole breaker rated according to the Specifications sec-

tion.

Figure 3.2 – Side Compartment

Figure 3.3 – Open Side Compartment

3.5 PROTECTION SYSTEMS

3.5.1 ALARMS

Highest Priority (Latching) Displayed on the control panel. They

must be cleared before the alarm message goes away. The alarm

log records each occurrence (see Appendix - "Menu System").

Low Oil Pressure (Shutdown Alarm)

A five (5) second delay on start-up and seven (7) second delay

once the engine is running.

This switch (Figure 3.4) has normally closed contacts that are

held open by engine oil pressure during operation. Should the oil

pressure drop below the five (5) PSI range, switch contacts close

and the engine shuts down. The unit should not be restarted until

oil level is verified.

Operation