- 22 -

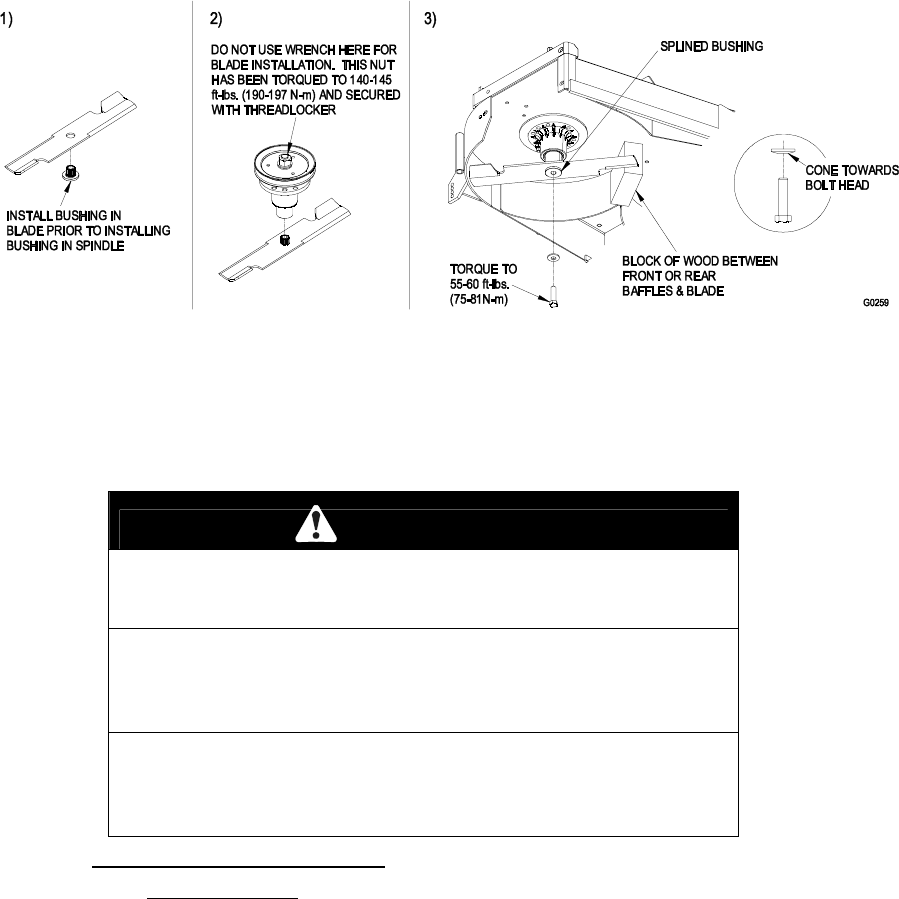

3) Install blade bolt and spring disc washer. Be sure the spring disc

washer cone is installed towards the bolt head. Place a block of wood

between front or rear baffles and the blade then torque the blade

bolts to 55-60 ft-lbs. (75-81 N-m).

FIGURE 6

BLADE BOLT INSTALLATION

IMPORTANT: DO NOT use components other than the original blade, blade

bushing, spring disc washer, and blade bolt supplied with the unit. Failure to

use all original components and assembled as shown will increase the risk of a

blade bolt becoming loose or weak after striking a foreign object.

CAUTION

POTENTIAL HAZARD

♦ Operating a mower deck with loose or weakened blade

bolts can be dangerous.

WHAT CAN HAPPEN

♦ A loose or weakened blade bolt could allow a blade

rotating at a high speed to come out from under the deck,

causing serious injury or property damage.

HOW TO AVOID THE HAZARD

♦ Always re-install original Exmark blades, blade bushings,

spring disc washers, and blade bolts in the correct

positions as shown.

6.1.6 Check safety interlock system:

Service Interval

: Daily

a) Check starting circuit. Starter should crank with operator in seat; parking

brake engaged, and with PTO disengaged. Try to start with operator out of

seat; parking brake engaged, and PTO disengaged; starter must not

crank. Try to start with operator in seat, parking brake disengaged and

PTO disengaged; starter must not crank. Try to start with operator in seat,

parking brake engaged and PTO engaged; starter must not crank.

b) Check kill circuits: Run engine at one-third throttle with PTO and parking

brake disengaged; lift yourself off the seat (but do not get off the machine)

engine must stop after 1/2 second has elapsed.

c) Run engine at one-third throttle with PTO and parking brake engaged; lift

yourself off the seat (but do not get off the machine) engine must stop after

1/2 second has elapsed.

NOTE: If machine does not pass any of these tests, Do Not operate. Contact

your authorized EXMARK Servicing Dealer.