Maintenance

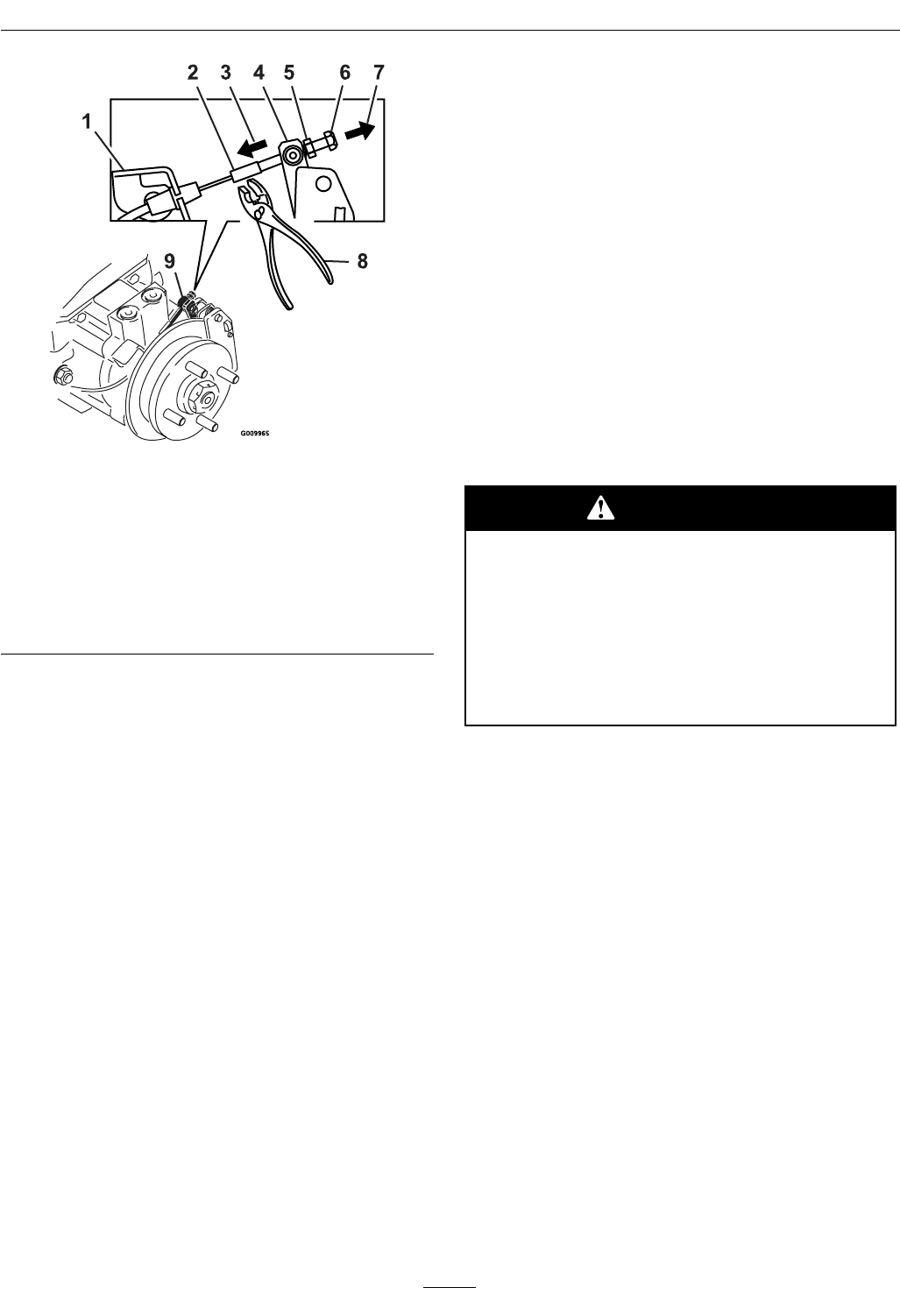

Figure 32

Left Hand Brake Shown

1. Cable anchor

6. Lock nut

2. Threaded rod 7. Pull cable threaded rod

this direction

3. Push lever this direction 8. Hold threaded rod here

4. Caliper lever arm 9. Swivel (pivot head)

5. Standard nut (shown

against swivel)

Note the order of the standard nut and lock nut

(no nut on the cable anchor side of the swivel).

10. Release hold on the caliper lever and cable. The

wheel hub should turn by hand in both directions

relative to the caliper; some friction/resistance

is acceptable.

11. If there is no movement between the hub rotor

and the caliper then back off the standard nut one

turn from the swivel and repeat step 10 (drive

release valves must be in the “released” position

on the hydros).

12. If the hub rotor moves very freely relative to the

caliper, then tighten the standard nut one turn

against the swivel and repeat step 10.

13. Once step 10 is achieved, hold the threaded rod

end with a tool and tighten the lock nut against

the standard nut. Do Not allow the cable to turn

when the nuts are tightened.

14. Rotate the drive wheel release handle to the

“operating” position. Refer to the Drive Wheel

Release Valves section in Operation.

15. Repeat on the opposite side of machine.

16. Install the rear tires and torque lug nuts to 90-95

ft-lb (122-129 N-m).

17. Remove jack stands.

Electric Clutch Adjustment

No adjustment necessary.

Motion Control Linkage

Adjustment

Located on either side of the fuel tank, below the seat

are the pump control linkages. Rotating the pump

linkage with a 1/2 inch wrench allows ne tuning

adjustments so that the machine does not move in

neutral. Any adjustments should be made for neutral

positioning only.

WARNING

Engine must be running and drive

wheels must be turning so motion control

adjustment can be performed. Contact with

moving parts or hot surfaces may cause

personal injury.

Keep ngers, hands, and clothing clear of

rotating components and hot surfaces.

1. Prior to starting the engine, push the deck lift

pedal and remove the height of cut pin. Lower

deck to the ground.

2. Raise the rear of machine up and support with

jack stands (or equivalent support) just high

enough to allow drive wheels to turn freely.

3. Remove the electrical connection from the seat

safety switch, located under the bottom cushion

of the seat. The switch is a part of the seat

assembly.

4. Temporarily install a jumper wire across the

terminals in the connector of the main wiring

harness.

5. Start engine. Brake must be engaged and

motion control levers out to start engine.

Operator does not have to be in the seat

because of the jumper wire being used. Run

engine at full throttle and release brake.

6. Run the unit at least 5 minutes with the drive

levers at full forward speed to bring hydraulic oil

up to operating temperature.

42