19

REPLACEMENT OF ENGINE OIL

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of

replacement.

ATTENTION: In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil,

conrm that the engine main unit and engine oil are sufciently cooled down. Otherwise, there may remain a risk of

scald.

Note: If the oil lled above the limit, it may be contaminated or may catch re with white smoke.

Interval of replacement: Initially, every 20 operating hours, and subsequently every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classication SF Class or higher (4-stroke engine oil for automobile)

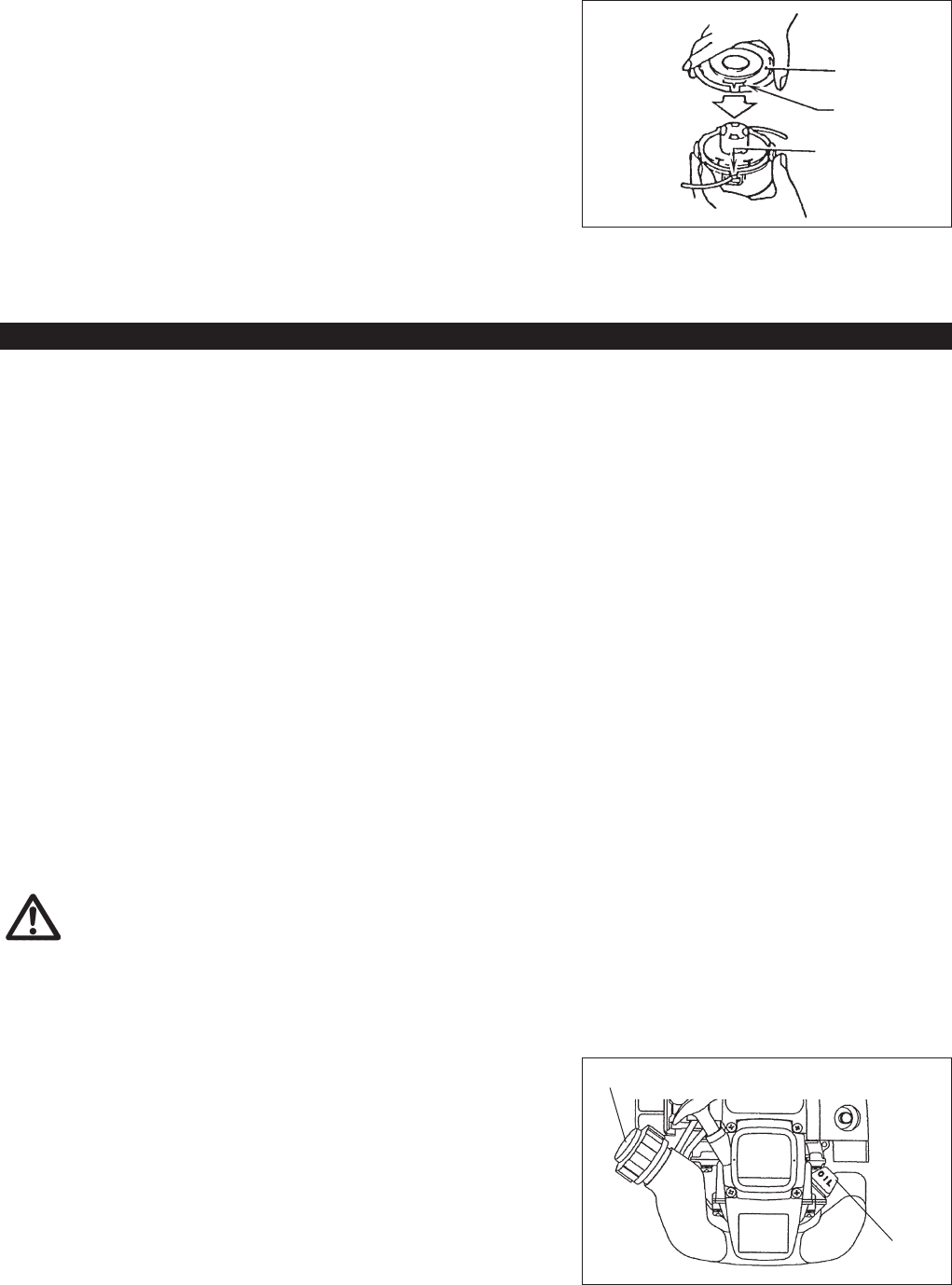

– Align the protrusion on the underside of the cover with the slots of the

eyelets.

Then push cover rmly onto the housing to secure it.

Cover

Protrusion

Slot of eyelet

In replacement, perform the following procedure.

1) Conrm that the tank cap is tightened securely.

2) Detach the oil gauge.

Keep the oil gauge free from dust or dirt.

Fuel tank cap

Oil gauge

CAUTION: Before doing any work on the Petrol Brushcutter, always stop the engine and pull the plug cap off the spark plug (see “checking the

spark plug”).

Always wear protective gloves!

To ensure a long service life and to avoid any damage to the equipment, the following servicing operations should be performed at regular

intervals.

Daily checkup and maintenance

– Before operation, check the machine for loose screws or missing parts. Pay particular attention to the tightness of the cutter blade or nylon

cutting head.

– Before operation, always check for clogging of the cooling air passage and the cylinder ns.

Clean them if necessary.

– Perform the following work daily after use:

• Clean the Petrol Brushcutter externally and inspect for damage.

• Clean the air lter. When working under extremely dusty conditions, clean the lter the severall times a day.

• Check the blade or the nylon cutting head for damage and make sure it is rmly mounted.

• Check that there is sufcient difference between idling and engagement speed to ensure that the cutting tool is at a standstill while the

engine is idling (if necessary reduce idling speed).

If under idling conditions the tool should still continue to run, consult your nearest Authorized Service Agent.

– Check the functioning of the I-O switch, the lock-off lever, the control lever, and the look button.

SERVICING INSTRUCTIONS