23

Headlight Bulb Replacement

Replace headlight bulbs as follows:

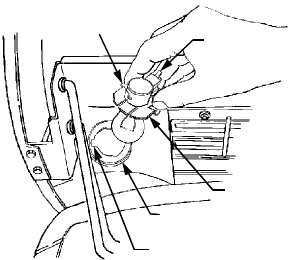

(See Figure 20)

1. After noting which wire connects

to each terminal, unplug the wire

harness leads from the headlight

socket terminals.

2. Rotate the socket assembly as

follows to remove from the

reflector housing:

Figure 20

• Left headlight — appoximately 1/4

turn counterclockwise.

• Right headlight — approximately

1/4 turn clockwise.

3. Push the bulb inward and turn

counterclockwise to remove from

the socket.

4. Align the post of the bulb base

with the notch in the socket, then

push the bulb inward and turn

clockwise to lock

5. With the terminals pointing

upward, align the tab of the

socket with the notch of the

reflector. Push the socket inward

and turn as follows to lock:

• Left headlight-1/4 turn clockwise.

• Right headlight-1/4 turn counter-

clockwise.

6. Connect the wire harness leads to

the appropriate socket terminals.

Tail Light Bulb Replacement

Each tail light assembly has two

lightbulbs. Access the back side of the

tail lights from under the rear fender.

NOTE: Because of the close proximity

of the fuel tank, caution should be

taken when removing the tail light

sockets from the reflector housings.

The bulbs can be pulled from the

sockets and dropped into the reflector

housing, requiring removal of the

reflector housing to retrieve the bulb.

Replace a tail light bulb as follows:

• Turn the light socket counterclock-

wise to align the socket tabs with

the notches in the tail light reflector.

• Once aligned, carefully pull light

socket out of the tail light reflector.

• Pull the light bulb from the socket

and replace with like part.

• Align the tabs of the socket with the

notches in the reflector and carefully

insert the socket. Turn the socket

fully clockwise to lock in place.

Tire Inflation

Keep the tires inflated to the

recommended pressure. Improper

inflation will affect tire life and operator

comfort, and also could affect the level

of the mower deck and quality of cut.

See the tire side wall for proper

inflation range.

Ensure that the valve caps are

securely tightened in place to prevent

air loss and to protect the valve core.

Do not overload the tractor tires by

mounting equipment on the tractor

which exceeds the load capacity of the

size of the tires on the tractor.

Checking Transmission Oil Level

NOTE: Check the oil level only while

the engine is stopped and the tractor

is level.

Check the oil level of the transmission

case before each use to see that it is

filled to the correct level. Before

checking the transmission oil level,

clean the area around the

Transmission Oil Fill/Dipstick to

prevent debris from entering the

transmission case. Always keep the oil

level between the “FULL” and the

“ADD” marks on the dipstick. When

checking the oil level, the dipstick

Terminals

Socket

Reflector Housing

Reflector Notch

Socket Tab