14

5

Making

Adjustments

WARNING

Read, understand, and

follow all instructions

and warnings on the

machine and in this

manual before operat-

ing.

Never attempt to

make any adjustments

while the engine is

running, except where

specified in operator’s

manual.

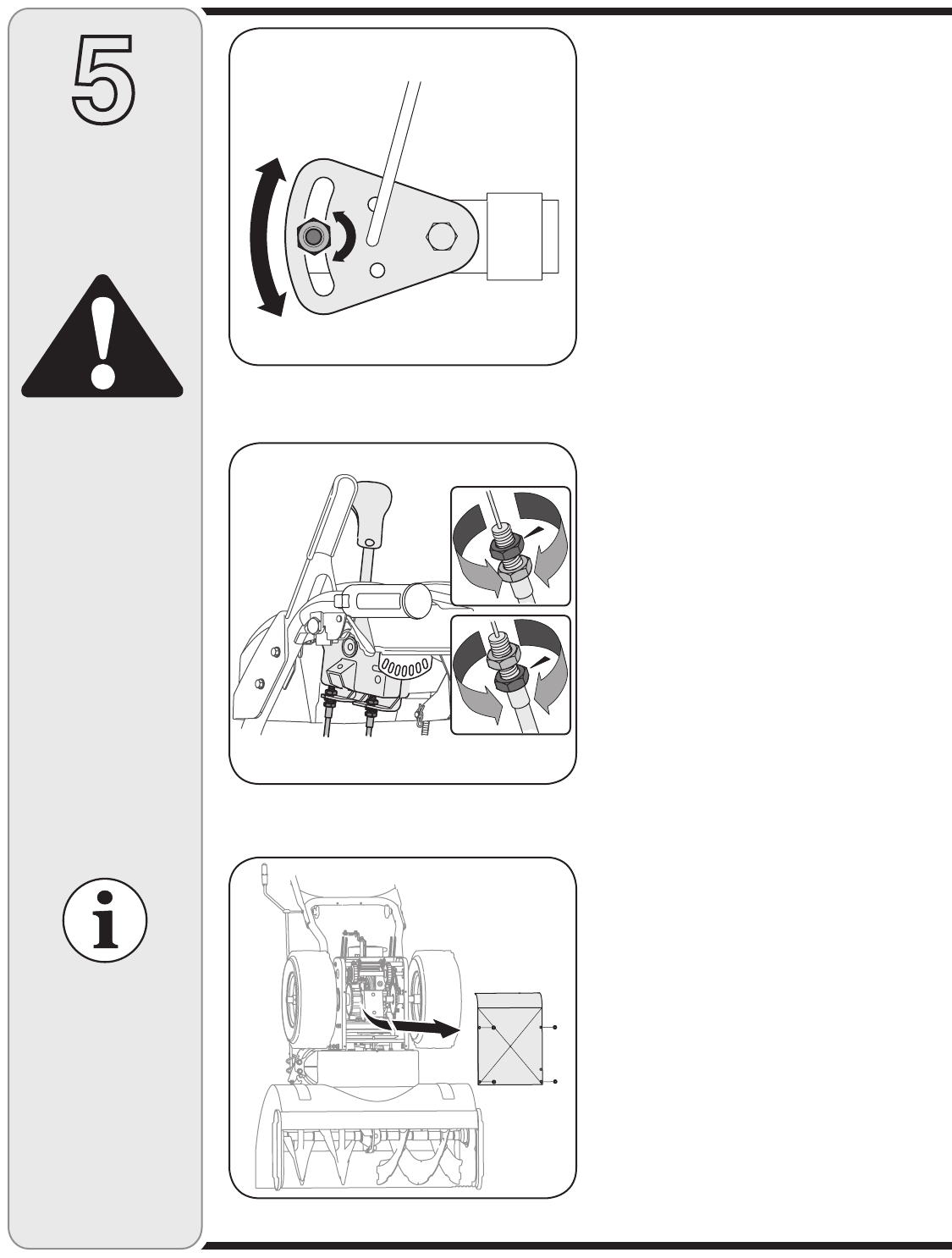

Shift Cable

If the full range of speeds (forward and reverse) cannot

be achieved, refer to the figure to the left and adjust the

shift cable as follows:

1. Place the shift lever in the fastest forward speed

position.

2. Loosen the hex nut on the speed selector pivot

bracket. See Figure 5-1.

3. Pivot the bracket downward to take up slack in the

cable.

4. Retighten the hex nut.

5. If further adjustment is needed, you may also utilize

the upper or lower hole in the pivot bracket.

6. Check for correct adjustment before operating the

snow thrower.

Chute Control

Once a season or every 25 hours of operation, whichever

is earlier, check whether the two-way chute control™

cables have slackened. If the chute pitch cannot be

moved up or down, the chute control cables will have to

be adjusted.

To adjust these cables, proceed as follows:

1. To tighten cable, loosen the top nut and tighten the

bottom nut on the cable.

2. Adjust equally on both sides by working on both

cables. See Figure 5-2.

Drive Control

Refer to the Final Adjustment section of the Assembly

instructions to adjust the drive control. To further check

the adjustment, proceed as follows:

1. With the snow thrower tipped forward (be certain to

drain gasoline or place plastic film under the gas cap if

the snow thrower has already been operated), remove

the frame cover underneath the snow thrower by

removing the self-tapping screws. See Figure 5-3.

2. Locate the opening between the axle support bracket

and the front frame support (See Figure 5-4). Looking

through this opening, with the drive control released,

there must be 1/8” clearance between the friction

wheel and the drive plate in all positions of the shift

lever.

3. With the drive control engaged, the friction wheel must

contact the drive plate. See Figure 5-4.

4. If there is no friction wheel clearance, or the friction

wheel does not solidly contact the drive plate, re-

adjust the lock nut on the lower end of the drive cable

following the instructions in the Assembly section.

5. Reassemble the frame cover.

NOTE: If you placed plastic film under the gas cap earlier,

remove it now.

Figure 5-1

Figure 5-2

Figure 5-3

Specifications are

subject to change

without notification

or obligation. Images

may not reflect your

exact model and

are for reference

purposes only.