38

• Stop the engine before checking the fuel line

hoses and clamps.

• Check that the fuel line hose clamps are snugly

securing the hoses to their respective fittings.

Replace any damaged clamps.

• Check the fuel hoses for wear or deterioration,

and any damaged hoses should be replace

immediately.

• After replacing a fuel line, it will be necessary to

bleed air from the fuel system before starting the

engine.

IMPORTANT: When servicing the fuel line hoses and

clamps, care should be taken to prevent dirt or dust

from entering the fuel system. If replacing a fuel line

hose, inspect the new hose to make certain no dirt or

debris has entered the hose.

ENGINE OIL AND OIL FILTER

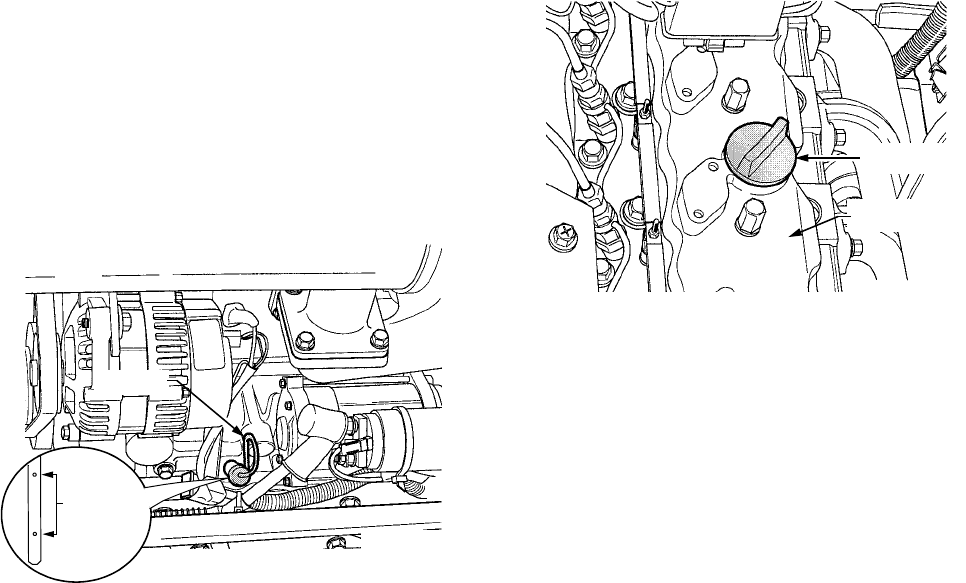

Checking the Engine Oil Level

Check the engine oil level before each use. If

checking the oil level after running the engine, wait at

least 5 minutes after stopping the engine to get an

accurate reading.

• Remove the left side panel.

• Clean the area around the dipstick to prevent

debris from entering the crankcase; then with-

draw the dipstick from the engine and wipe clean.

See Figure 55.

Figure 55

• Fully re-insert the dipstick into the engine.

• Withdraw the dipstick again, and check that the

oil level is between the upper and lower marks on

the dipstick. Always keep the oil level between

the full and add marks on the dipstick.

• Reinsert the dipstick into the engine and press

firmly into place.

Adding Engine Oil

If the oil level is low, add enough oil to bring the level

up to the full mark on the dipstick. Do not overfill the

crankcase. Refer to the LUBRICATION TABLE for

the proper type of oil to add to the crankcase. When

possible, maintain the brand and viscosity of oil

previously used to service the engine.

• Place the tractor on a level surface and engage

the parking brake. Stop the tractor engine and

remove the ignition key.

• Clean the area around the oil filler cap to prevent

debris from entering the crankcase.

Figure 56

• Turn the oil filler cap counterclockwise to unscrew

from the rocker arm cover.

• SLOWLY pour oil into the crankcase until the oil

level reaches the “FULL” mark on the dipstick.

• Insert the oil fill cap into the rocker arm cover and

turn clockwise until fully tightened. Reinsert the

dipstick into the engine and push firmly into

place.

IMPORTANT: The oil fill cap and dipstick must

always be installed securely in place when the engine

is running. Severe engine damage could result from

failure to do so.

Operating

Range

Dipstick

Oil Fill Cap

Rocker Arm

Cover