ENGINE

Maintenance, repair, or replacement of

the emission control devices and sys-

tems, which are being done at the

customers expense, may be performed

by any non-road engine repair establish-

ment or individual.Warranty repairs must

be performed by an authorized engine

manufacturer'seawice outlet.

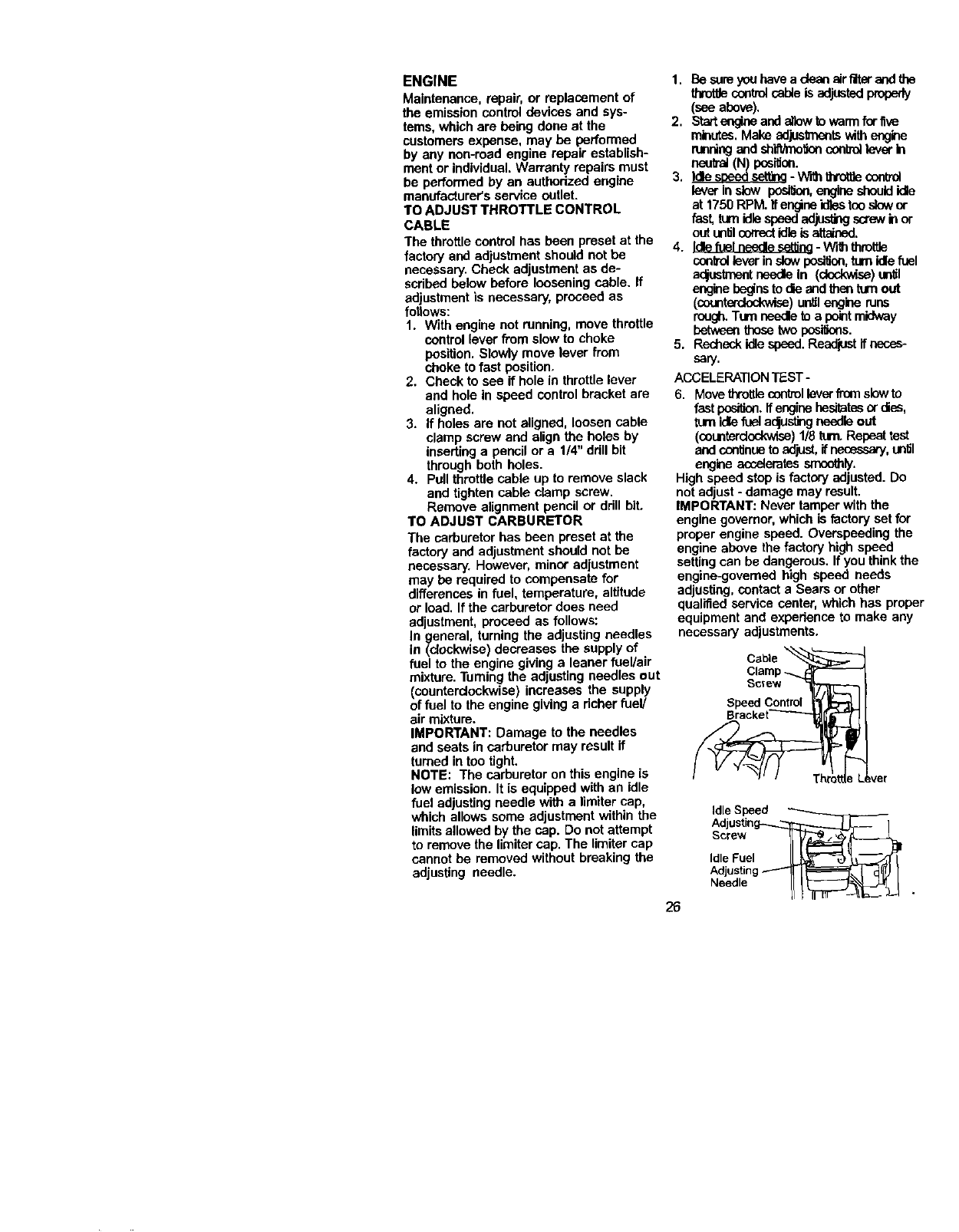

TO ADJUST THROTTLE CONTROL

CABLE

The throttlecontrol has been presetat the

factory and adjustment should not be

necessary. Check adjustment as de-

scribed below before loosening cable. If

adjustment is necessary, proceed as

fotiows:

1. With engine not running, move throttle

control lever from slow to choke

position. Slowly move lever from

choke to fast position,

2. Check to see if hole in throttle lever

and hole in speed control bracket are

aligned.

3. If holes are not aligned, loosen cable

clamp screw and alignthe holes by

inserting a pencil or a 1/4" drillbit

through both holes.

4. Pull throttlecable up to remove slack

and tighten cable clamp screw.

Remove alignment pencil or drillbit,

TO ADJUST CARBURETOR

The carburetor has been preset at the

factory and adjustment should not be

necessary. However, minor adjustment

may be required to compensate for

differences in fuel, temperature, altitude

or load. If the carburetor does need

adjustment, proceed as follows:

In general, turning the adjusting needles

in (dockwise) decreases the supply of

fuel tothe engine giving a leaner fuel/air

mixture.Turning the adjusting needles out

(counterclockwise) increases the supply

offuel to the engine givinga richerfuel/

air mixture.

IMPORTANT: Damage to the needles

and seats in carburetor may result if

turned intoo tight.

NOTE: The carburetor on this engine is

low emission. It is equipped with an idle

fuel adjustingneedle with a limiter cap,

which allows some adjustment within the

limitsallowed by the cap. Do not attempt

to remove the limitercap. The limiter cap

cannot be removed without breaking the

adjusting needle.

26

1. Be sureyouhavea dean airfilterandthe

throttlecontrolcableisadjustedproperly

(see above).

2. Startengtheand allewto warmfor five

minutes.Make acrjuslmentswithengine

runningand sh_lten conb'o_leverIn

neutral(N) position.

3. Idlesl_d ssttina -"W_ththrotaecontrol

leverin stow posilien,enginesbeuididle

at 1750 RPM. Ifengineidlestooslowor

fust, tam idlespeedadjustingscrewinor

outunf_lcorrect idleisattained.

4. Idlefuel needlesettina-WiththmttJe

ccoifd lever inslowpesilion, turnidlefuel

acjustmentneedle In (clockwise)until

enginebeginstod'=eandthenturnout

(counterclockwise) untilengineruns

rough. Turnneedleto apointmidway

betweenthose twopesi_ons.

5. Recheckidlespeed. Readjustif neces-

sary.

ACCELERATIONTEST -

6. Movethrottlecontrolleverfrom slowto

fastpeail_. Ifenginehesitatesor dies,

turnidlefuelaclustingneedleout

(counterdGd_dse)1/8turn.Repeattest

and continuetoadjust,ifnecessary,un_l

engineaccelerates smoothly.

Highspeed stopis factory adjusted. Do

notadjust - damage may result.

IMPORTANT: Nevertamper with the

engine governor,which is factory set for

proper engine speed. Overspeeding the

engine above the factory high speed

setting can be dangerous. If youthinkthe

engine-govemed high speed needs

adjusting,contact a Sears or other

qualified service center, which has proper

equipment and experience to make any

necessary adjustments.

Cable

Clamp -_

Screw

Speed Control

IdleSpeed

Adjustin_

Screw

IdleFuel

Needle