ASSEMBLY

Read these instructions and Operator's Manual in its en-

tirety before you attempt to assemble or operate your new

high pressure washer. Your high pressure washer has, for

the most part, been assembled at the factory, except those

parts left unassembled_ Before you can operate your new

high pressure washer, you must assemble the wheel kit and

properly connect the high pressure hose.

IF YOU HAVE ANY PROBLEMS WITH THE ASSEMBLY

OF YOUR PRESSURE WASHER, PLEASE CALL THE

PRESSURE WASHER HELPLINE AT 1-800-222-3136.

TOOLS REQUIRED FOR ASSEMBLY

,, Mallet

o 2 adjustable wrenches OR the following wrenches:

o 5/16" (8mm) combination wrench

* 1/2" (13mm) combination wrench

,, 11/16" (18ram) combination wrench

° 7/8" (22mm) combination wrench

o 15/16" (24mm) combination wrench

TO REMOVE PRESSURE WASHER FROM

CARTON

o Remove box for spray gun assembly and support legs

= Remove accessories box from carton.

° Remove wire basket (wrapped in plastic)

o Removeyour high pressure washer.

Refer to Page 6, "Contents of Hardware Pack" for an

illustrated listing of all items included with your pressure

washer. Become familiar with each piece before assem-

bling pressure washer. Check all contents against illustra-

tions on Page 6. If any parts are missing or damaged, call

Pressure Washer Helpline. at 1-800-222-3136.

HOW TO SET UP YOUR PRESSURE WASHER

TO INSTALL THE WHEEL KIT

Installing the wheel kit requires the tools listed above, the

guide handle and items included in the parts carton.

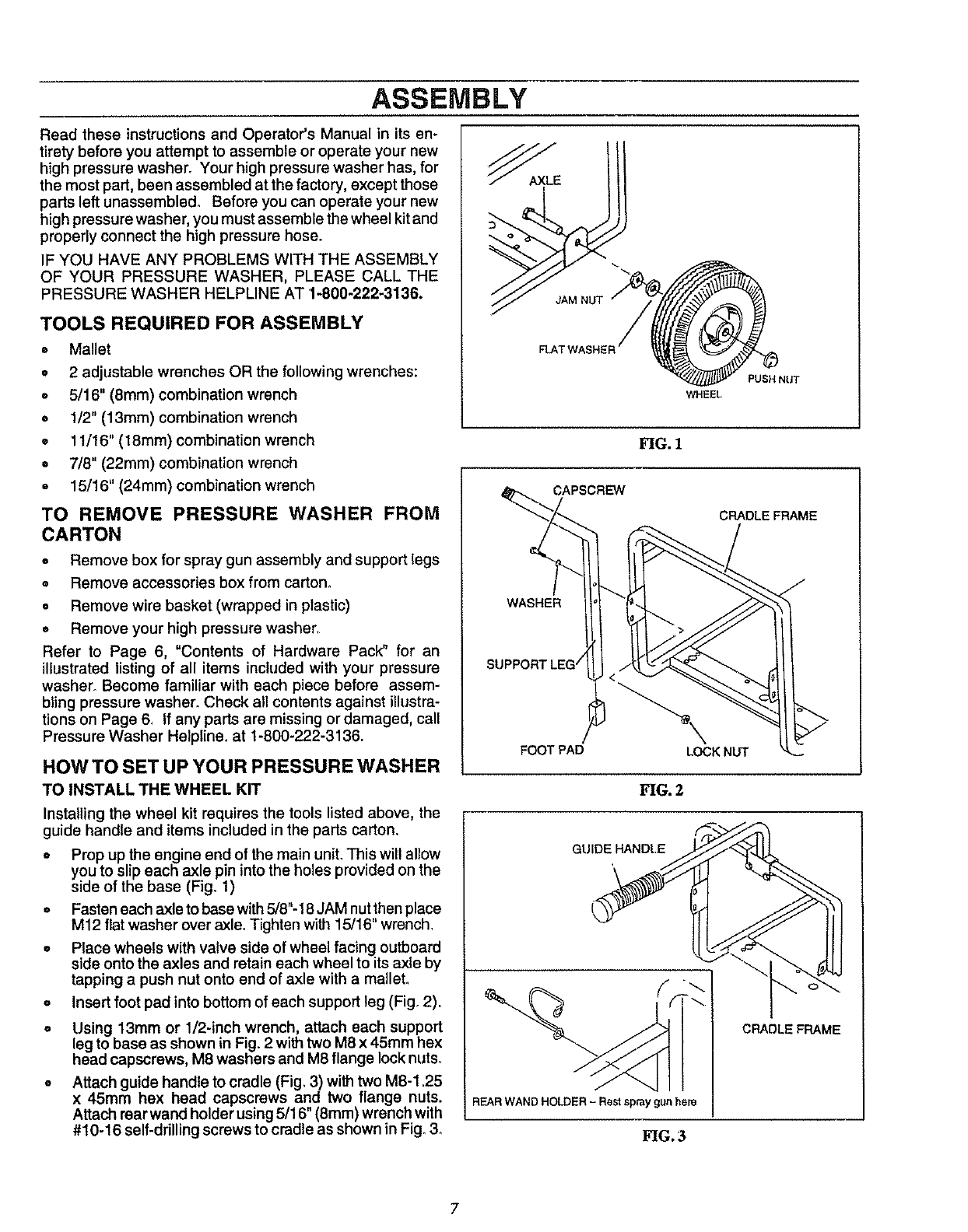

,, Prop up the engine end of the main uniL This will allow

you to slip each axle pin into the holes provided on the

side of the base (Fig. 1)

o Fasten each axle to base with 5/8"-18 JAM nut then place

M12 flat washer over axle. Tighten with 15/16" wrench.

= Place wheels with valve side of wheel facing outboard

side onto the axles and retain each wheel to its axle by

tapping a push nut onto end of axle with a malleL

o Insert foot pad into bottom of each support leg (Fig. 2).

= Using 13mm or 1/2-inch wrench, attach each support

leg to base as shown in Fig. 2 with two M8 x 45mm hex

head capscrews, M8 washers and M8 flange lock nuts.

o Attach guide handle to cradle (Fig. 3) with two M8-1.25

x 45mm hex head capscraws and two flange nuts.

Attach rear wand holder using 5/16" (8mm) wrench with

#10-16 self-drilling screws to cradle as shown in Fig. 3_

FIG. 1

QAPSCR_

HEEL

CRADLE FRAME

WASHER

FOOT PAD

/

<

GUIDE HANDLE

REARWAND HOLDER - Restspraygun here

FIG. 3

CRADLE FRAME

7