CUSTOMER RESPONSIBlUTES

CLEAN/REPLACE SPARK PLUG

SERVICE AIR CLEANER

I A CAUTION: NEVER RUN THIS UNIT WITHOUTTHE 1

COMPLETE AIR CLEANER SYSTEM INSTALLED|

ON THE ENGINE. THIS COULD RESULT IN FRE-/

MATURE WEAR TO THE ENGINE. /

Your engine will not run properly and may be damaged if

you run it using a dirty air cleaner.

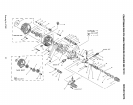

Clean or replace the air cleaner paper filter (Fig. 25) once

every 25 hours of operation or once a year, whichever'

comes first. Clean or replace more often if operating under

dusty or dirty conditions. Clean foam pre-filter every 25

hours of operation or sooner under dusty conditions.

FIG. 25

FOAM

COVER

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This willhelp your

engine to start easier and run better° Replace with Cham-

pion RC12YC or equivalent type spark plug.. Set spark plug

gap 0.030 inch (0.76mm).

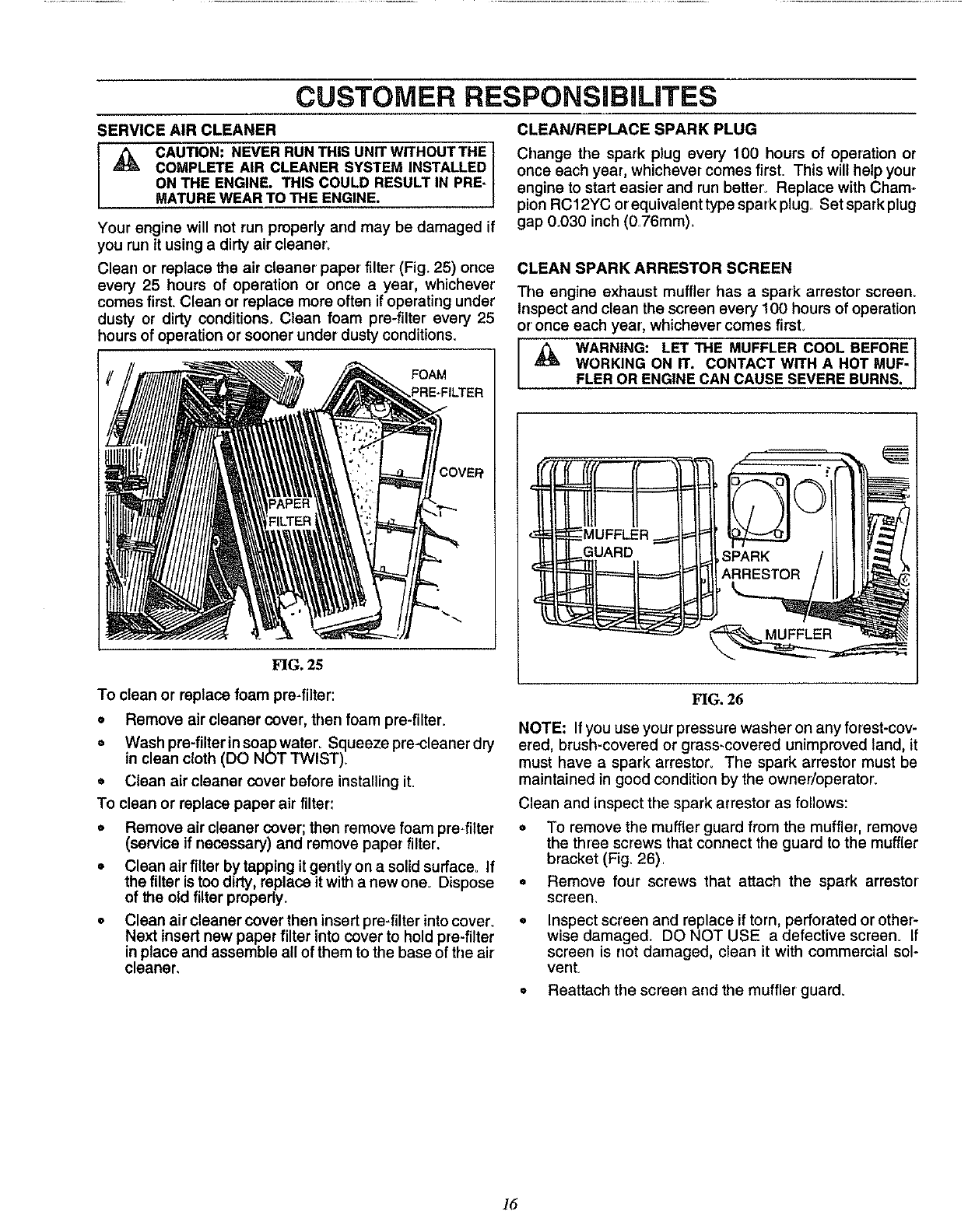

CLEAN SPARK ARRESTOR SCREEN

The engine exhaust muffler has a spark arrestor' screen.

Inspect and clean the screen every 100 hours of operation

or once each year, whichever comes first.

WARNING; LET THE MUFFLER COOL BEFORE l

WORKING ON IT. CONTACT WITH A HOT MUF-

FLER OR ENGINE CAN CAUSE SEVERE BURNS.

c

To clean or replace foam pre-filter:

= Remove air cleaner cover, then foam pre-filter.

,, Wash pre-filter insoap water. Squeeze pre-cleaner dry

in clean cloth (DO NOT TWIST).

,, Clean air cleaner cover before installing iL

To clean or replace paper air filter:

,, Remove air cleaner cover; then remove foam pre4ilter

(service if necessary) and remove paper filter.

,, CleanairfilterbytappingitgenUyonasolidsurface. If

the filter is too dirty, replace it with a new one. Dispose

of the old filter properly.

• Clean air cleaner cover then insert pre-filter into cover.

Next insert new paper filter into cover to hold pre-filter

in place and assemble all of them to the base of the air

cleaner.

FIG. 26

NOTE: If you use your pressure washer on any forest-cov-

ered, brush-covered or grass-covered unimproved land, it

must have a spark arrestor. The spark arrestor must be

maintained in good condition by the owner/operator.

Q

O

Clean and inspect the spark arrestor as follows:

o To remove the muffler guard from the muffler, remove

the three screws that connect the guard to the muffler

bracket (Fig. 26).

Remove four screws that attach the spark arrestor

screen.

Inspect screen and replace if torn, perforated or other_

wise damaged. DO NOT USE a defective screen° If

screen is not damaged, clean it with commercial sol-

vent

Reattach tile screen and the muffler guard,

16