16

To Adjust Blade Spring

•

The tension of the blade adjust spring may be altered

to permit the blade to tilt forward to bypass solid

obstructions. To change the spring tension, adjust

the nuts at upper end of the spring bolt. Turn the nuts

counterclockwise to relieve tension and clockwise to

increase tension. Refer to fi gure 19 on page 12.

To Adjust Blade Shoes

•

The blade shoes at the ends of blade may be raised

for close work on smooth surfaces or lowered to raise

the blade to work on rough or uneven areas. Make

sure both shoes are set evenly and that the nuts are

tightened securely. See fi gure 28.

SERVICE AND ADJUSTMENTS

FIGURE 28

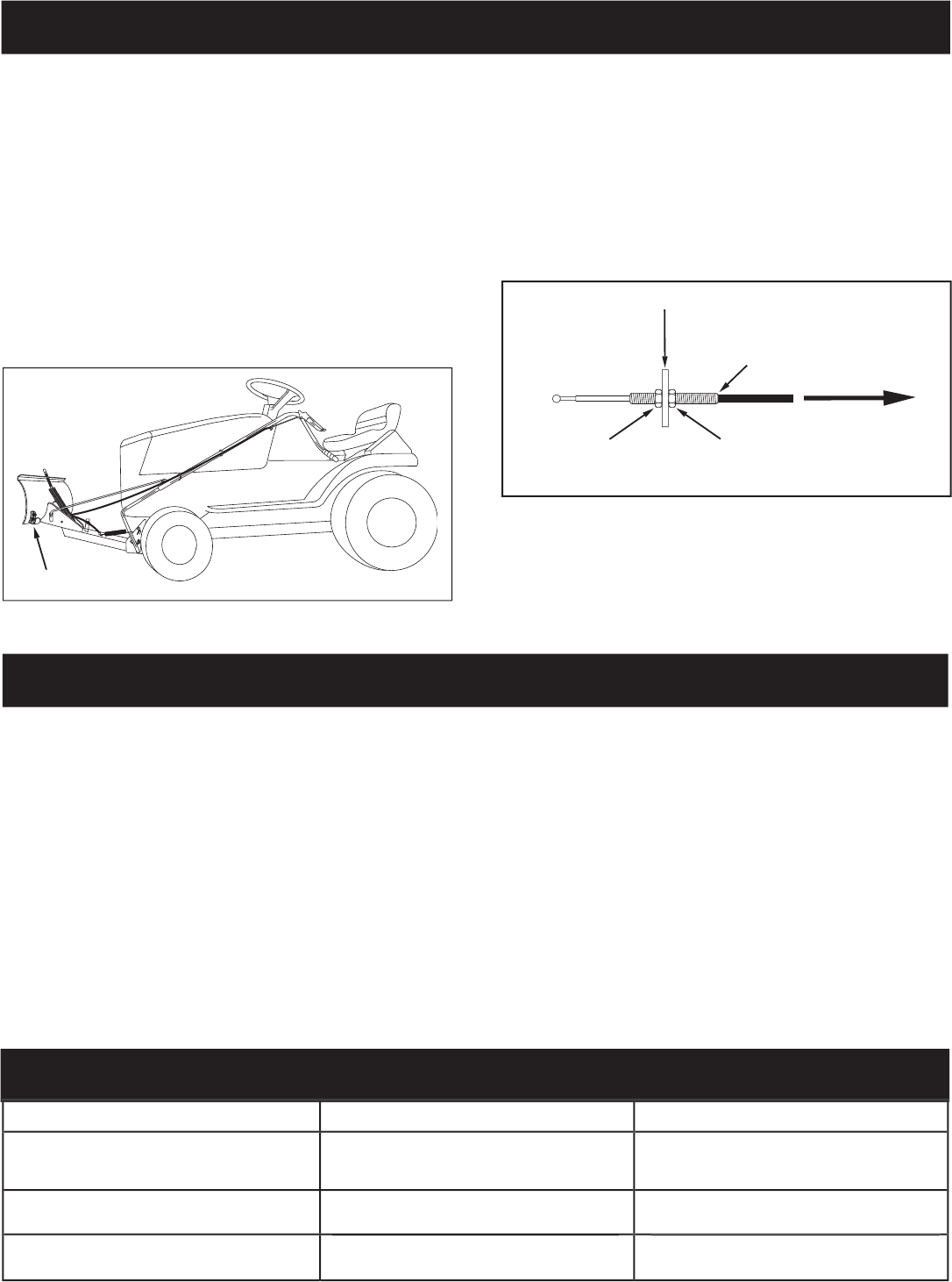

To Adjust the Blade Pivot Lock Mechanism

•

If the blade will not unlock and pivot, the angle lock

bars are not disengaging from the slots in the pivot

plate. To correct, adjust the 5/16" hex jam nuts to draw

the end of the control cable back towards the cable

mount bracket. The less the threaded end of the cable

extends through the bracket, the more the angle lock

bars can retract to disengage from the slots in the

pivot plate. See fi gure 29.

FIGURE 29

Recommendations When Storing

•

When the snow blade is not being used, remove all

dirt and rust and touch up with paint.

•

Touch up bare metal with paint or apply a light coat of

grease or rust preventive.

•

Lubricate all pivot points and all points shown in fi gure

27, page 15 in the maintenance section.

•

Store in a dry area, protected from weather.

STORAGE

To Remove Blade From Tractor

•

Lower the blade head to the ground with the blade in

the center (straight ahead) position.

•

Remove the two clevis pins which fasten the

blade's hanger brackets to the tractor's mower deck

suspension brackets (or frame brackets). See fi gure

11 on page 10.

•

Remove the clevis pin that fastens the blade's rear

mounting bracket to the tractor's drawbar and drop the

rear of the blade frame to the ground. See fi gure 10

on page 10.

•

Remove the frame brackets (if used). See fi gure 3 on

page 6.

•

Back the tractor off of the blade assembly.

TROUBLESHOOTING

CAUSE

Lift mechanism is binding

Handle tube is binding on lift rod.

Lock mechanism is out of adjustment

Lock mechanism is out of adjustment

and is not disengaging.

PROBLEM

Blade is diffi cult to raise.

Blade is diffi cult to pivot.

Blade will not unlock to pivot.

CORRECTION

Lubricate pivot points as shown in

fi gure 27 on page 15.

Lubricate lift handle rod as instructed

in fi gure 27 on page 15.

Refer to the Service and Adjustments

Refer to the Service and Adjustments

section on this page.

CABLE MOUNT BRACKET

5/16" HEX

JAM NUT

CONTROL

CABLE

5/16" HEX

JAM NUT

BLADE SHOE