9

OPERATING INSTRUCTIONS

NOTE: Make sure you have a firm grip on the unit. The spinning

blade will contact the ground before the wheel does and

will create continuous forward thrust.

4. Walk slowly behind the unit while maintaining a firm grip on the unit.

TIPS FOR BEST EDGING RESULTS

• Do not force the edger. Edge the first time at a lesser depth,(No

more than 1/2” depth cut per pass), then do the area again with a

deeper setting.

• Walk the edger at a slow, even pace.

• Check the blade condition. As it wears it becomes smaller, thus

reducing the cutting depth performance. Replace with a new blade

when the blade has worn to the blade’s wear limit holes (Fig. 18).

ADJUST BELT TENSION

If blade fails to turn when the bail is pulled, then:

1. Locate small thumb wheel on top of the belt housing (Fig. 17).

2. Turn the wheel clockwise 1 revolution to increase the tension

on the belt.

3. Try pulling the bail and see if the blade turns. If not, repeat step

2 until the blade turns.

MAINTENANCE AND REPAIR INSTRUCTIONS

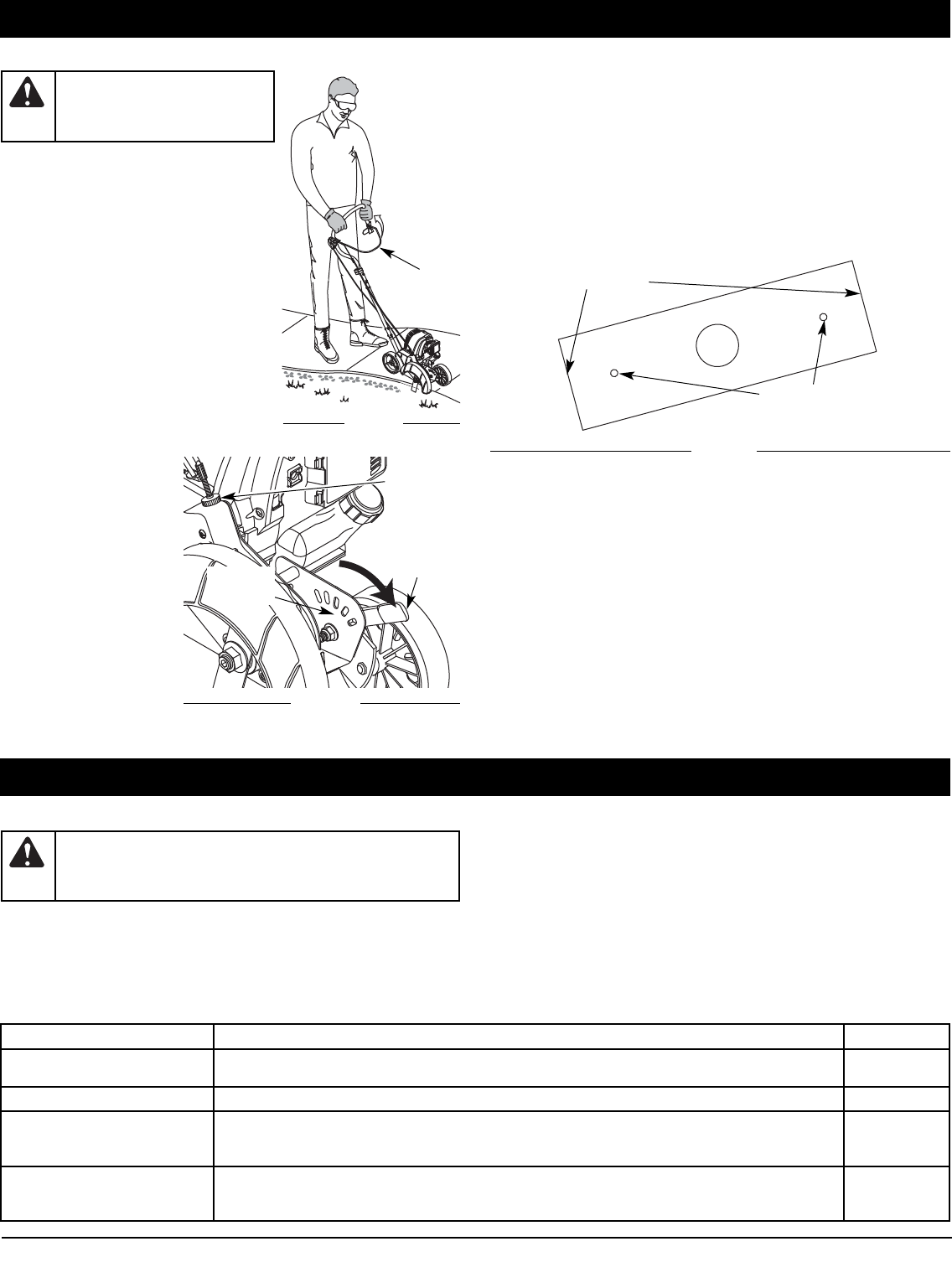

HOLDING THE UNIT

Before operating the unit, stand in the

operating position (Fig. 16). Check for the

following:

• The operator is wearing eye protection

and proper clothing.

• Both hands are holding the handle bar

firmly.

• The edger wheel adjusted for proper

cut depth as shown in Figure 17 and

edger positioned as shown in Fig. 16.

ADJUSTING EDGER CUTTING DEPTH

1. Grasp the depth adjustment lever

located beside the front wheel (Fig. 17).

2. To raise the cutting blade, move the

lever toward the front of the wheel

bracket (Fig. 17).

3. To lower the cutting blade, move the

lever toward the rear of the wheel

bracket.

OPERATING THE UNIT

Once the unit has started:

1. Tilt the unit back until

the blade is not in

contact with the

ground.

2. Lift the bail (Fig. 16)

and hold it against the

unit’s handle to

engage the blade and

keep it rotating.

3. Slowly lower the unit

until the front wheel is

in contact with the

ground.

Fig. 16

Fig. 18

Blade Edges

Wear Limit

Holes

WARNING:

Always wear

eye, hearing, foot and body

protection to reduce the risk of

injury when operating this unit.

WARNING:

To prevent serious injury, never perform

maintenance or repairs with unit running. Always service

and repair a cool unit. Disconnect the spark plug wire to

ensure that the unit cannot start.

Perform these required maintenance procedures at the frequency

stated in the table. These procedures should also be a part of any

seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or

skills. If you are unsure about these procedures take your

unit to a Sears or other qualified service dealer.

NOTE: Maintenance, replacement, or repair of the emission control

devices and system may be performed by a Sears or other

qualified service dealer.

In order to assure peak performance of your engine, inspection of

the engine exhaust port may be necessary after 50 hours of

operation. If you notice lost RPM, poor performance or general lack

of acceleration, this service may be required. If you feel your engine

is in need of this inspection, refer service to a Sears or other

qualified service dealer for repair. DO NOT attempt to perform this

process yourself as engine damage may result from contaminants

involved in the cleaning process for the port.

FREQUENCY MAINTENANCE REQUIRED SEE

Before using

Fill fuel tank with fresh fuel

Check Oil

p. 7

p .10

Every 10 hrs Clean and re-oil air filter p. 10

After 1st 10 hrs

After 25 hrs & Every 25 hrs

Every 50 hrs

Change Oil

Change Oil

Clean Spark Arrestor

p. 10

p. 10

p. 12

Every 10 hrs

Every 25 hrs

Every 25 hrs

Check rocker arm to valve clearance and adjust

Check rocker arm to valve clearance and adjust

Check spark plug condition and gap

p. 11

p. 11

p. 12

• MAINTENANCE SCHEDULE •

Lift

Bail

Fig. 17

Thumb

Wheel

Wheel

Bracket

Depth

Adjustment

Lever