CALL TOLL FREE 1-800-DR-OWNER 23

CHAPTER 6

TROUBLESHOOTING

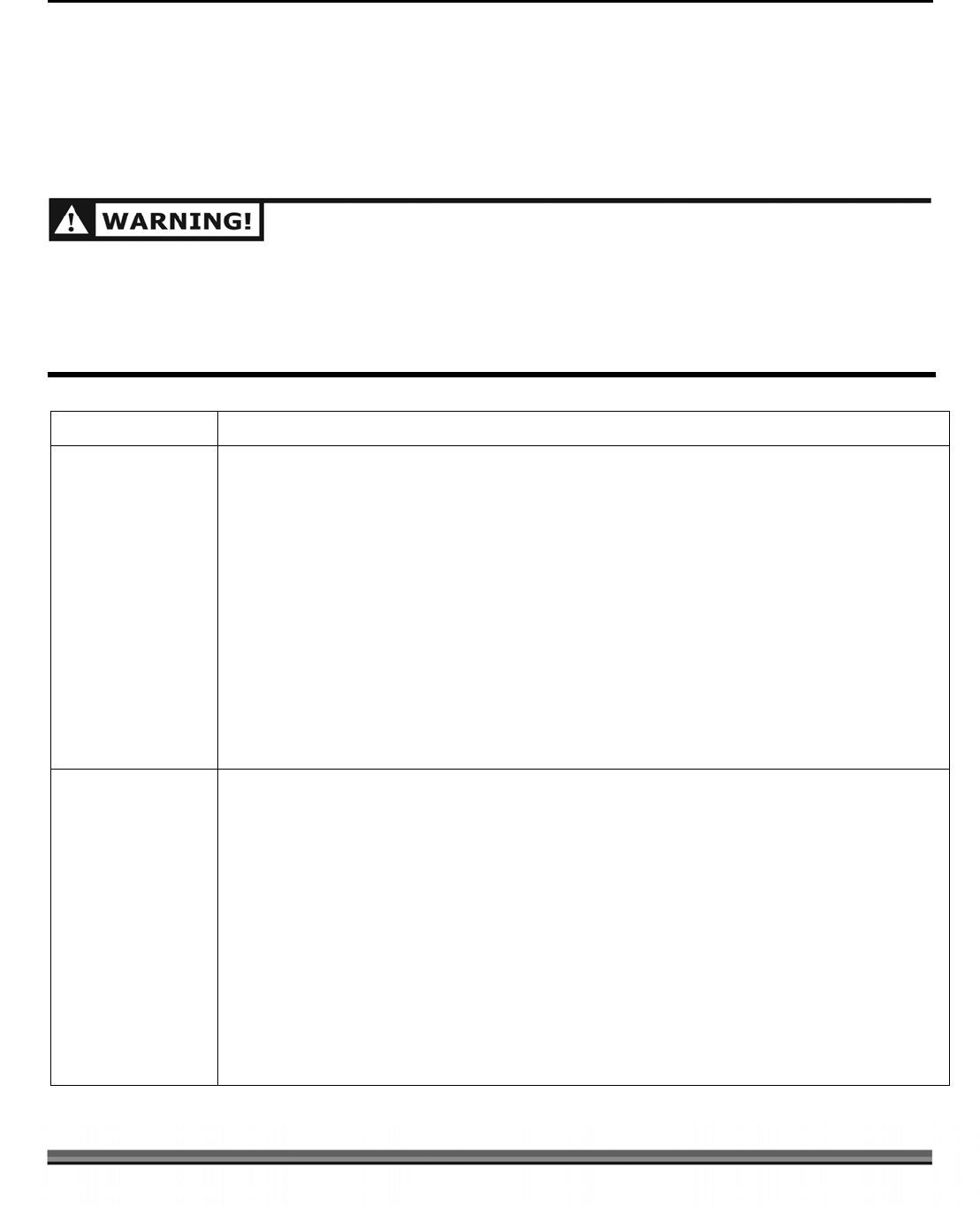

Consult the Troubleshooting Table below for common problems and their solutions. If you continue to

experience problems, call our Technical Support Representatives at 1-800-DR-OWNER.

Troubleshooting Table

• BEFORE PERFORMING ANY MAINTENANCE, YOU MUST UNPLUG THE WOOD SPLITTER FROM THE

POWER SOURCE. MAKE SURE THE HYDRAULIC SYSTEM IS DEPRESSURIZED (SEE PAGE 7), AND MAKE

SURE THE FLUID HAS COOLED.

• READ THE "GENERAL SAFETY RULES" (CHAPTER 2) OF THIS MANUAL BEFORE PERFORMING ANY

REPAIRS OR MAINTENANCE.

SYMPTOM POSSIBLE CAUSE

Ram will not move

or is slow to

respond.

⇒ The Air Bleed Screw may be open. See page 13, Step 3.

⇒ The motor Reset has tripped; push the Reset Button. See Figure 1 on page 10.

⇒ Bleed any accumulated air from the hydraulic system. See page 20, step 5.

⇒ The wood splitter may not be on a level surface. See page 13, step 1.

⇒ Make sure the voltage at the outlet or extension cord connection to the wood splitter

is at least 105VAC.

⇒ If you are using an extension cord, make sure that the cord is less than 33 feet long

and is not smaller than 12 AWG wire.

⇒ The hydraulic fluid may be low. Check and adjust the level as required; see page 20.

⇒ In extreme high temperature and heavy rapid use, the hydraulic fluid may have over

heated. Allow the machine to cool.

⇒ The wood you are splitting may be too hard, it has knots, or its fiber is very tough.

Log fails to split.

⇒ Check the possible causes for the previous Ram operation symptom.

⇒ Incorrect positioning of the log; re-position the log flat on the splitting beam with

the ends squarely against the Ram face and Splitting Wedge.

⇒ Log exceeds permitted dimensions or the wood is too hard for the capacity of the

machine. The maximum log length is 20" with a maximum diameter of 12" for the

DR 5 -TON ELECTRIC WOOD SPLITTER.

⇒ The wedge has burrs or nicks and needs sharpening; see page 20.

⇒ There may be a hydraulic fluid leak. Locate the leak using a piece of cardboard

under the machine and call 1-800-DR-OWNER (376-9637), or a qualified hydraulic

mechanic for assistance, to replace worn components.

⇒ Hydraulic pressure is too low. Call 1-800-DR-OWNER (376-9637), or a qualified

hydraulic mechanic for assistance to replace worn components.