SECTION V

ASSEMBLY

IMPORTANT

Tighten all fasteners to specifications on Torque

Chart unless otherwise indicated.

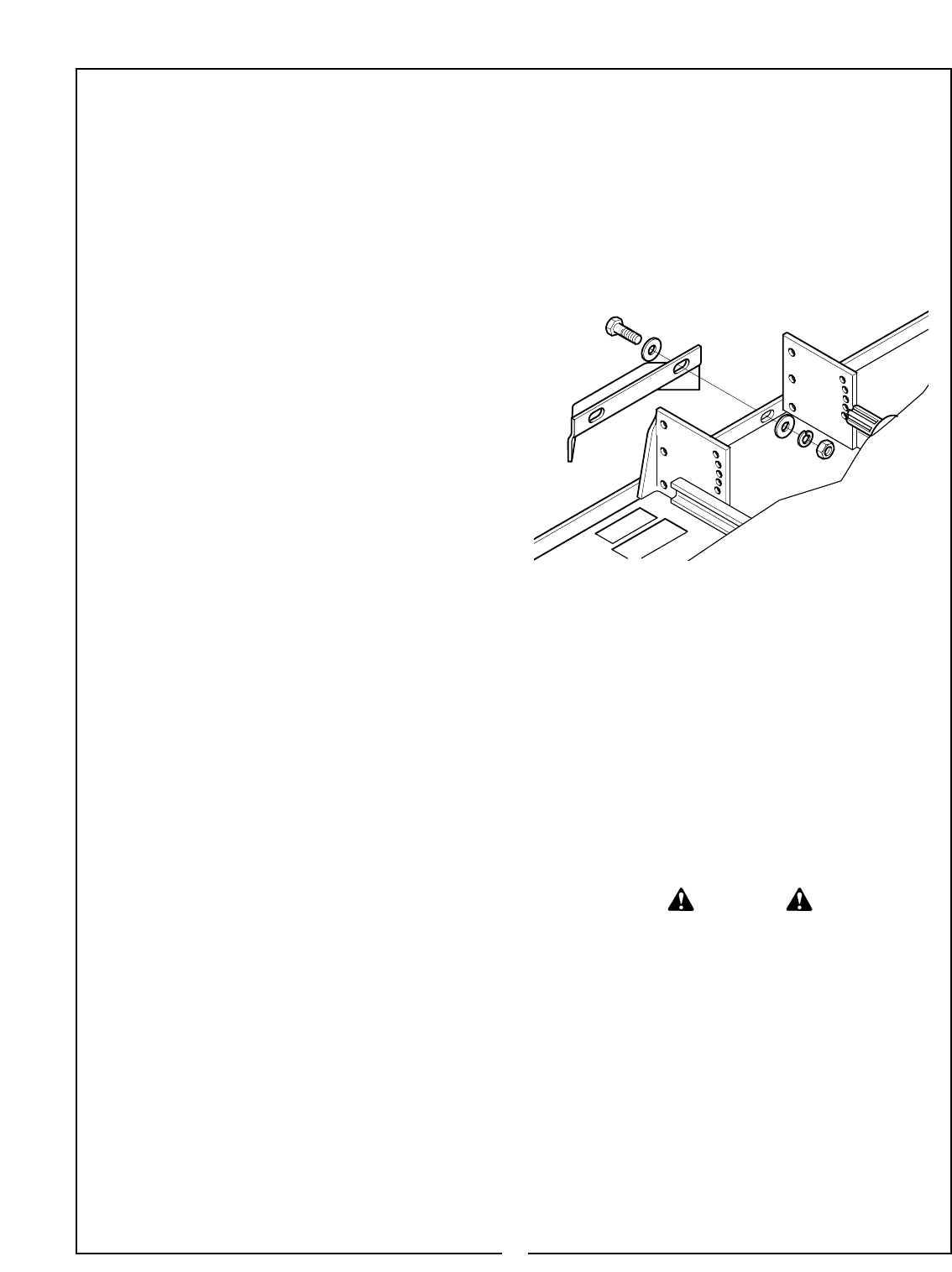

5-1 STANDARD 3-POINT HITCH (Figure 5-1)

To attach a standard duty hitch to your cutter:

Remove the lift pins and all bolts from the hitch.

Install the A-frame struts of the assembly between

the mounting brackets on the base frame. Extend

the 3-point hitch yoke between the A-frame and the

brackets at the rear of the machine and bolt into

place. Replace lift pins and bolts at bottom of A-

frame struts, then tighten all bolts and lift pins

securely.

5-2 HEAVY DUTY 3-POINT HITCH

To attach a heavy duty hitch to your cutter:

Remove the bolts from the hitch. Install the mast

weldment between the mounting brackets on the

base frame. Extend the 3-point hitch yoke between

the top of the mast to the brackets at the rear of the

machine and bolt into place. Fasten the mast to the

deck brackets using 7/8 x 2-1/2” bolts, lockwashers

and nuts in the top holes and 5/8 x 2” bolts, lock-

washers and nuts in the bottom holes. Tighten all

bolts. Arrange the lift pins and flexible link according

to your tractor’s requirements. Refer to Figure 2-1.

5-3 TAILWHEEL ASSEMBLY

Connect your cutter to the tractor and lift it high

enough for the caster wheel assembly to clear the

ground. Install the tailwheel frame as shown. Insert

the caster fork up through the pivot tube. Fasten in

place with lock collar and roll pin. To adjust to

desired cutting height, bolt end of adjusting bracket

to lugs on base frame and fasten other end to tail-

wheel bracket using the desired adjusting hole.

Tighten all bolts securely.

5-4 GEARBOX INPUT SHIELD

Remove four existing bolts from around input

shaft in front of gearbox. Fasten metal shield bracket

to gearbox using these bolts. Fasten plastic shield

(with access opening to the top) to the shield bracket

using four 5/16 x 3/4” bolts, flatwashers, lockwash-

ers and nuts.

5-5 FRONT CHAIN GUARDS (Standard) &

REAR CHAIN GUARDS (Optional)

Position chain assembles against mainframe as

shown and fasten with 1/2 x 1-1/2” bolts, flatwash-

ers, lockwashers and nuts. (Figure 5-1)

5-7 DRIVELINE INSTALLATION

(Slip Clutch Optional)

A. Remove pivot bolt from spline end of clutch.

Remove inspection cover from clutch shield.

B. Slide clutch onto gearbox input shaft aligning

bolt holes with slot in input shaft. Fasten with clamp

bolts, lockwashers and nuts. Torque to 30 ft./lbs.

C. Loosen eight nuts retaining clutch springs

1/3 turn or until spring can be turned with fingers.

D. With tractor at idle speed, engage tractor

PTO drive 2-3 seconds. Clutch should slip with-

out turning blades.

E. Retighten nuts to original position. If adjust-

ment is necessary, refer to Section 4-6.

OVER-TIGHTENING SPRING NUTS MAY

CAUSE DAMAGE TO IMPLEMENT AND/OR

TRACTOR DUE TO INCORRECT SLIP

CLUTCH TORQUE SETTING. ALWAYS

FOLLOW THE PROPER ADJUSTMENT PRO-

CEDURE.

IMPORTANT

Before operation,fill gearbox with EP80W-90

gear oil to check plug on rear of gearbox. Allow

time for oil to seep through bearings into lower

housing, then recheck oil level. Insure that vent

hole in fill plug is open to allow pressure to

escape from gearbox during operation.

WARNING

15

5-6 FRONT GUARD ASSEMBLY (Optional)

Fasten guard to center front of mainframe

using1/2 x 1-1/2” bolts, flatwashers, lockwashers

and nuts.

Figure 5-2 Front Guard