11

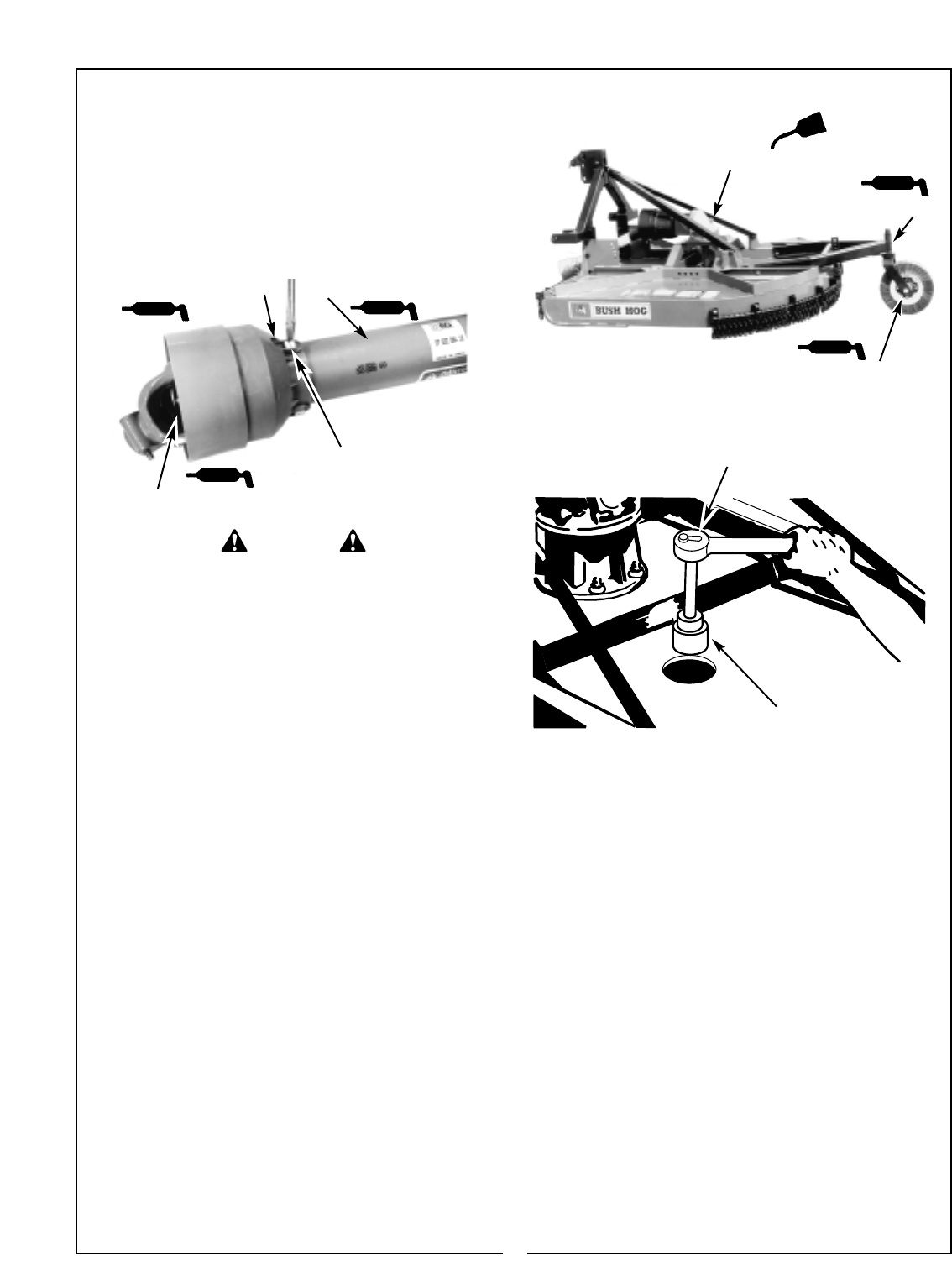

Figure 4-1 Lubrication

(3) Before Each Use

(2) Before Each Use

(6) Before Each Use

4-4 BLADE REPLACEMENT (Figure 4-2)

It is not necessary to remove the complete blade

holder assembly to replace the blades. Blade bolts

are accessible through a hole in the top of the cutter

deck. Always replace both blades on a spindle using

two blades having the same weight. Use only gen-

uine Bush Hog replacement parts.

A. Raise cutter and securely block in position.

Figure 4-2 Blade Nut Removal

5. PTO Driveline - Disconnect PTO driveline, pull

the two sections apart, apply thin coat of multi-

purpose grease to inside of outer (female) sec

tion. Reassemble sections and install. Pull each

section to be sure driveline and shields are

securely connected. Make certain PTO shielding

is in good condition.

6. Gearbox - Add EP80W-90 gear oil as necessary

to bring oil level to check plug on top of housing.

THE CUTTER CAN FALL FROM HYDRAULIC

SYSTEM FAILURE. TO AVOID SERIOUS

INJURY OR DEATH, SECURELY SUPPORT

CUTTER BEFORE WORKING UNDERNEATH.

WARNING

4-3 BLADE HOLDER ASSEMBLY

REMOVAL AND INSTALLATION

A. Remove the lower shaft nut and lockwasher.

B.Wearing heavy gloves, grasp blade holder and

pull off tapered shaft. If stuck, align bolt with access

hole in top of cutter deck. Using sledge hammer and

a piece of pipe, strike blade bar. Rotate pan to the

other blade bolt and strike blade bar. Repeat until

blade holder comes off. Care should be taken not to

damage blade bolt threads.

REPLACEMENT

A. Replace blade holder and tighten the lower

shaft nut to 600 ft./lbs. If a torque wrench is not

available, the nut should be tightened with a

wrench having a three foot handle, or a section

of pipe over the wrench handle, if a wrench of

this size is not available.

B. Strike the blade holder several times with a

heavy hammer and retighten lower shaft nut. This

should be repeated several times.

D. Assemble new blades to blade holder using

blade bolts, nuts and lockwashers. Tighten nuts to

450 ft./lbs. Strike blade bolt head with heavy ham-

mer to seat, then retighten.

E. Check to be sure blades swing 360° freely.

If blades will not swing freely, remove, locate

problem, and repair. Operating cutter when

blades will not swing freely will cause excessive

vibration, damaging implement.

4-5 SLIP CLUTCH OPERATIONAL CHECK

After implement had been stored for 30 days or

more, perform the following operational check:

A. Loosen eight nuts retaining clutch springs 1/3

turn or until spring can be turned with fingers.

B. With tractor at idle speed, engage tractor PTO

drive for 2-3 seconds. Clutch should slip without

(4) Before Each Use

(5) Before Each Use

(1) Before Each Use

1-11/16” Socket

B. Remove nuts from blade bolts using a 1-11/16”

socket through the access hole in the deck.

C. Inspect blade bolt shoulder for wear. Replace

if necessary.

To remove yoke shield:

Turn slotted head 90° with

screwdriver, remove turn screw

and slide cover back.