7

Model 1609A Only

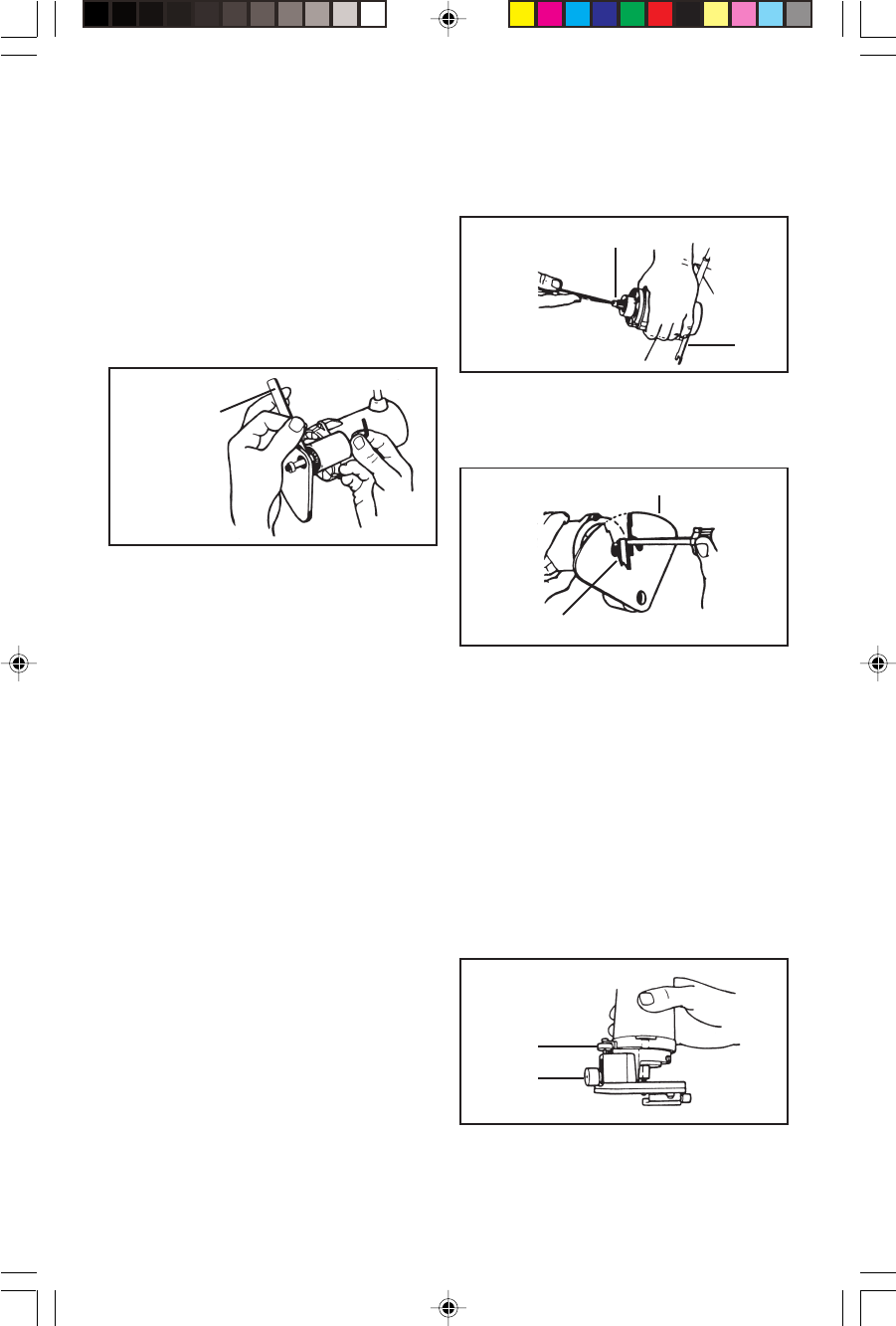

Insert the 4mm hex wrench supplied into the

hole in the top of the offset base to hold the

spindle in position, and loosen the collet in a

counterclockwise direction with one of the

combination wrenches supplied. Insert a lami-

nate trim bit into the collet as far as it will go,

and back out slightly until the cutters are 1/8"

to 1/4" away from the collet. Holding the

spindle firmly with the 4mm hex wrench,

tighten the collet in a clockwise direction with

the combination wrench to firmly grip the bit.

To remove bit, use the wrenches as described

above, and turn the collet in a counterclock-

wise direction until the bit can be pulled out.

Note that the collet is self-extracting; it is NOT

necessary to strike the collet to free the bit.

CAUTION! The minimum insertion of the bit

shank is 5/8" to ensure proper gripping and

minimize bit run-out.

Collet Care

With the router bit removed, continue to turn

the collet or collet nut counterclockwise until

it is free of the spindle and the collet can be

removed. To assure a firm grip, occasionally

blow out the collet with compressed air and

clean the taper in the spindle shaft with a tissue

or fine brush.

After cleaning, reinsert the collet and lightly

thread in place. To avoid damage, NEVER

tighten the collet or collet nut unless a bit is

inserted. Replace worn or damaged collets

immediately.

Assembling Motor to Base

All Models Except Model 1609A

Insert router motor into clamping ring 4. Ro-

tate motor to the desired position, and tighten

clamping ring screw 8 with a screwdriver. Be

sure clamping ring holds motor firmly before

turning tool "ON ", but do not overtighten the

ring.

Model 1609A Only

Remove collet and nut (if fitted) from motor

spindle as described earlier. Lock the armature

shaft with the combination wrench 14 fur-

nished, and screw the toothed pulley 15 in

place with a screwdriver. Remove the combi-

nation wrench, and with the clamping ring

loosened, slide the offset base assembly 16

into place on the motor as far as it will go.

As the base is installed, it is necessary to guide

the toothed belt 17 over the pulley by using a

screwdriver inserted through the U-shaped hole

in the sub-base. Position the motor in the base

in the most comfortable position to suit the

operator, and tighten the clamping ring firmly.

Do not overtighten.

Depth Adjustment

Model 1608, 1608LX Only

With the motor clamped in the base and the bit

installed, loosen knob 10 and raise or lower the

motor and cutter with adjusting screw 11 until

the desired amount of bit is exposed. Tighten

knob 10 and make a test cut in scrap material.

Repeat this procedure until the desired depth

of cut is achieved.

Fig. 6

16

17

Fig. 4

Wrench

Fig. 5

15

14

Fig. 7

10

11

BM 2610909755 7/01 7/26/01, 12:03 PM7