Section 5: Maintenance 13

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to

come to a complete stop, disconnect spark plug wire and move wire away from spark plug.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

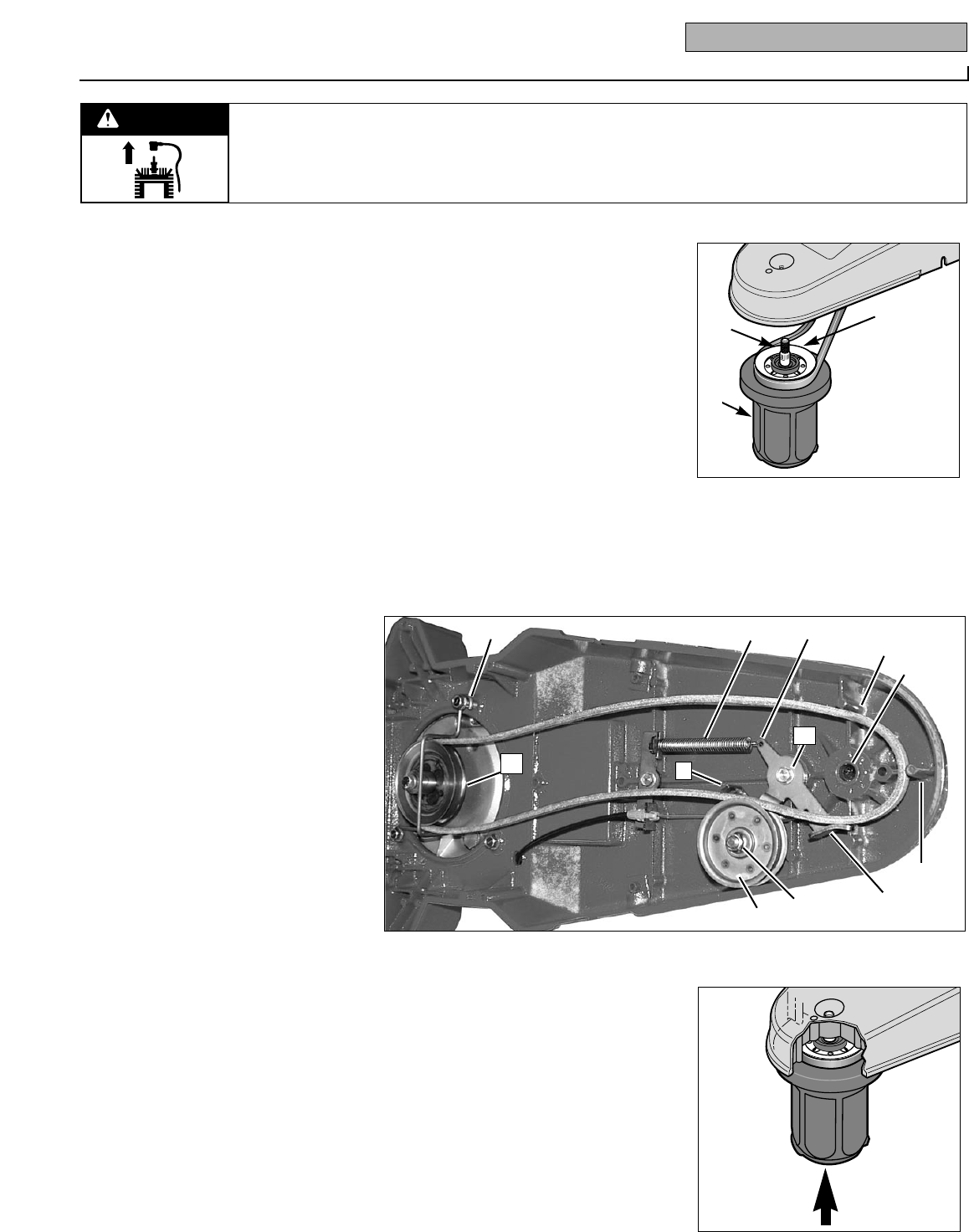

11. Using a 9/16" wrench and a 7/32" hex

(Allen) wrench, loosen the mounting nut

(G, Figure 5-6) and screw on the idler

pulley (I) a few turns, or until belt is free

to slip out between pulley and belt guide

(J). Remove belt.

12. Loosen rear belt guide screw (K,

Figure 5-6) enough to allow belt to be

removed from engine pulley (L). Remove

belt from unit.

BELT REPLACEMENT

1. Install belt on engine pulley (L, Figure

5-6) and retighten rear belt guide screw

(K) securely.

2. Route belt between idler pulley (I,

Figure 5-6) and belt guide (J), to inside of

brake arm (M), and next to die-cast belt

guides (N).

3. Securely tighten the mounting nut (G,

Figure 5-6) and screw in the idler pulley

(I).

4. Securely tighten the idler arm

mounting screw (S, Figure 5-6). After

tightening, check that idler arm is free to

rotate. If not, remove idler arm and check

for debris that may be interfering with

freedom of movement.

5. Look at the spindle head mounting

hole (O, Figure 5-6) and note the grooves

that are cut into the inner sides of the

hole. These grooves were formed by the

splines on the spindle shaft (E, Figure

5-5).

6. Install the belt on the spindle head

pulley (P, Figure 5-5) and insert the

spindle shaft (E) (with attached spindle

head assembly) into the spindle head

mounting hole (O, Figure 5-6). Rotate the

spindle head assembly to align the

splines on the spindle shaft with the

grooves in the mounting hole. Check

that the belt is still in the pulley groove

and is to the inside of the die-cast belt

guides (N, Figure 5-6).

7. Using a firm push on the spindle head

assembly (Figure 5-6A), seat the spindle

head assembly into the hole. Check that

the threaded end of the spindle shaft is

protruding through the bottom of the

hole.

8. Reinstall the flat washer (D, Figure 5-

4), Belleville washer (C) and nut (B) on

the spindle shaft. Note that the dished-in

side of the Belleville washer must face

the flat washer. Tighten the nut securely

(torque to 50 ft./lbs.), while checking fre-

quently to ensure that the spindle head

rotates freely. If the spindle head binds,

it could be due to the belt being pinched

between the spindle head and the belt

guides. If so, remove the spindle head

assembly and repeat steps 5-7.

9. Replace plastic plug (A, Figure 5-4).

10. Reattach the idler arm spring (R,

Figure 5-6) in the hole in the idler arm

(T).

11. A new belt may need to be adjusted

by following the Adjusting Trimmer Head

Engagement instructions in this Section.

Figure 5-5

Figure 5-6

E

F

P

R

T

K

N

N

O

M

G

I

S

J

L

Figure 5-6A